Steel Mill

Hydraulic Cylinder

What Are Steel Mill Hydraulic Cylinders?

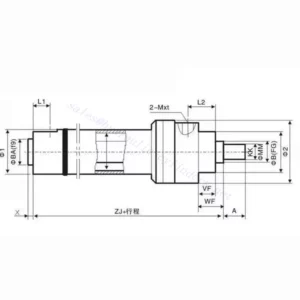

Steel mill hydraulic cylinders, encompassing furnace cylinders and metallurgical hydraulic cylinders, are robust actuators that convert hydraulic fluid energy into linear mechanical force, tailored for the severe demands of steel production. Constructed from high-strength steel with heat-resistant coatings, these hydraulic cylinders for steel mills endure pressures up to 5000 PSI, high ambient temperatures, and abrasive dust, ensuring durability in applications like furnace tilting, continuous casting mold oscillation, and automatic gauge control (AGC) in rolling mills.

Compliant with ISO and DIN standards, our heavy-duty steel mill hydraulic cylinders feature low-friction seals (e.g., Hunger DFE seals) for stick-slip-free operation and integrated position measuring systems for precision. Customizable bore sizes (up to 1400mm), stroke lengths, and mounting options (e.g., flange, earring, tripod) meet specific steel mill requirements, while energy-efficient designs reduce power consumption. From steel smelting to rail beam production, our energy-efficient furnace cylinders and custom metallurgical hydraulic cylinders enhance operational reliability and longevity.

Steel Mill Hydraulic Cylinders For Sale

-

Metallurgisk hydraulikksylinder av orkidétype med hodemetode

-

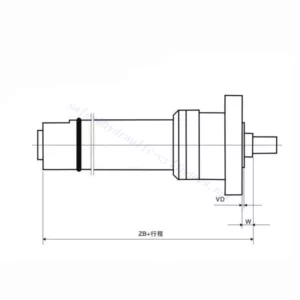

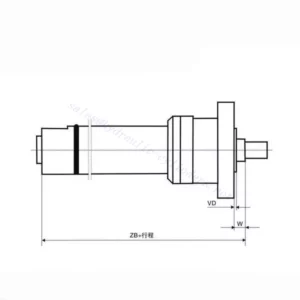

Metallurgisk hydraulikksylinder med hodestift

-

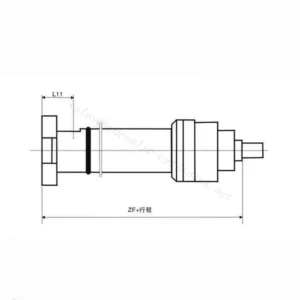

Metallurgisk hydraulikksylinder med rektangulær flens og hode

-

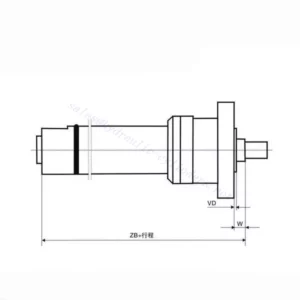

Metallurgisk hydraulikksylinder med rund flens på hodet

-

Metallurgisk hydraulikksylinder av orkidétype med bakre metode

-

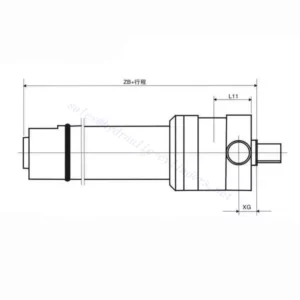

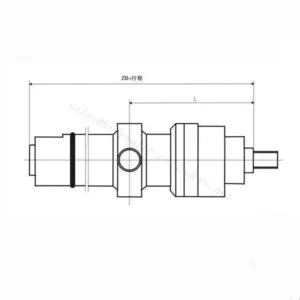

Metallurgisk hydraulikksylinder med midtstift

-

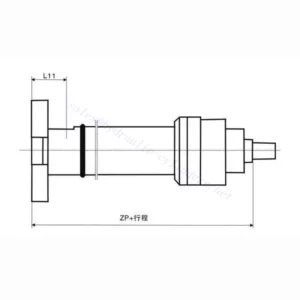

Metallurgisk hydraulikksylinder med bakre tapp

-

Rektangulær metallurgisk hydraulikksylinder med bakre rektangulær flens

-

Metallurgisk hydraulikksylinder med rund bakre flenser

-

Y-HG1 Noraml metallurgisk hydraulikksylinder

-

Y-HG1 Metallurgical Hydraulic Cylinder

-

Bakre metallurgisk hydraulikksylinder med en enkelt ørering

Steel Mill Hydraulic Cylinders Application

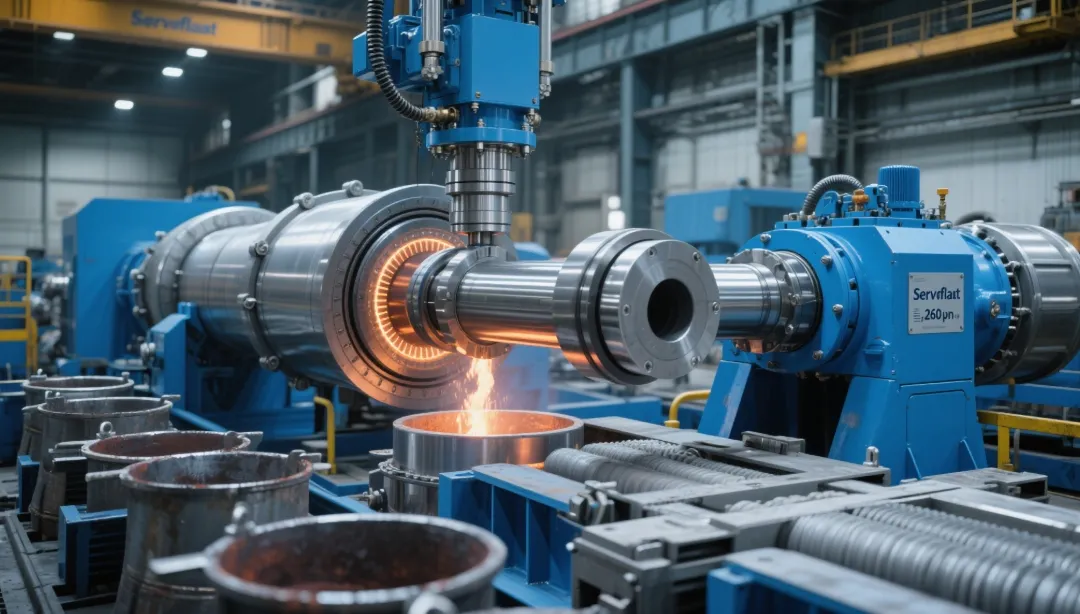

Furnace cylinders, a type of steel mill hydraulic cylinder, power furnace tilting systems in electric arc furnaces and blast furnaces, enabling precise tilting to pour molten steel. They operate in extreme heat (>100°C) and dusty environments, ensuring smooth, stick-slip-free movement.A steel smelting plant increased furnace tilting precision by 18% and reduced downtime by 12% with our durable steel mill hydraulic cylinders for furnace tilting.

Furnace Cylinder: Furnace Tilting Applications

Metallurgical hydraulic cylinders drive mold oscillation in continuous casting plants, preventing molten steel from sticking to the mold’s inner walls at frequencies up to 3 Hz. They ensure high-precision oscillation for superior steel surface quality.A continuous casting plant improved steel strand quality by 15% and extended cylinder service life to 6 years with our high-pressure metallurgical hydraulic cylinders for continuous casting.

Metallurgical Hydraulic Cylinder: Continuous Casting Mold Oscillation Applications

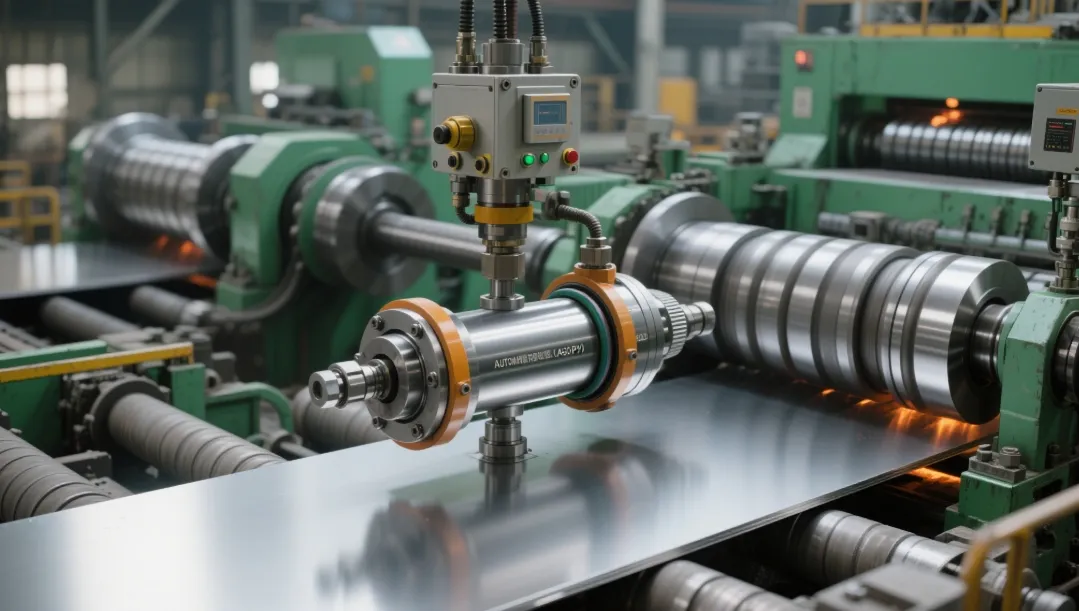

Metallurgical hydraulic cylinders, such as AGC cylinders, control roller adjustments in hot and cold rolling mills, achieving thickness accuracies of a few hundredths of a millimeter for sheet metal and rail beams. They withstand high-frequency operation and dusty conditions.A hot rolling mill reduced thickness deviations by 20% and improved production efficiency by 15% with our energy-efficient metallurgical hydraulic cylinders for hot rolling.

Metallurgical Hydraulic Cylinder: Automatic Gauge Control (AGC) Applications

Steel Mill Hydraulic Cylinder Maintenance Guide

Extend the lifespan of your steel mill hydraulic cylinder, including furnace cylinders and metallurgical hydraulic cylinders, with these expert tips, ensuring reliability in harsh steel mill environments. Regular maintenance minimizes downtime and optimizes performance.

1

Inspect Regularly

Inspect your steel mill hydraulic cylinder quarterly for wear, corrosion, or damage on seals, rods, and fittings, focusing on dust or heat damage in furnace or rolling mill areas. Use a flashlight and magnifying glass to detect micro-cracks or leaks, and maintain a log.

2

Clean Thoroughly

Clean your furnace cylinder or metallurgical hydraulic cylinder after use with a low-pressure washer (1000-1500 PSI) to remove dust, slag, or grease. Dry with a microfiber cloth to prevent corrosion. Avoid high-pressure washing to protect heat-resistant seals.

3

Lubricate Properly

Apply high-temperature grease (e.g., Shell Gadus S3 V220C, Mobilgrease XHP 222) to rods, seals, and pivot points to minimize friction in high-heat environments. Ensure even coverage without over-application to avoid dust attraction. Reapply after cleaning or prolonged use.

4

Protect Against Environmental Damage

Apply corrosion-inhibiting spray to rods and exposed surfaces after use to shield against rust in dusty, high-heat steel mills. Store spare cylinders in a dry, covered area, using waterproof covers and retracting rods to minimize exposure.

5

Schedule Professional Service

Annual servicing by certified technicians ensures your metallurgical hydraulic cylinder operates efficiently. Professionals perform pressure tests, seal replacements, and fluid analysis (replacing filters as needed). Schedule during planned downtime to avoid disruptions.

Hydraulic Cylinder Production Area

We are a leading manufacturer specializing in hydraulic cylinders and hydraulic systems, dedicated to delivering high-tech solutions. Our company primarily serves OEMs in industries such as construction machinery, aerial work platforms, sanitation vehicles, wind power, and agricultural machinery. We offer a versatile range of hydraulic cylinders with inner diameters ranging from +20 to 500 mm, boasting an impressive annual design capacity of 1.2 million units.

Our state-of-the-art facilities include a provincial research institute, a high-tech R&D center, and a specialized hydraulic product testing laboratory. We utilize advanced equipment such as dedicated turning centers, high-speed cutting and polishing machines, automatic processing and welding systems, automatic cleaning and assembly lines, fully automated flexible painting lines, and intelligent logistics assembly lines. This comprehensive production and testing capability enables us to maintain a strong technological development capacity, ensuring our manufacturing processes and product quality meet advanced national standards.

Visit our VR hydraulic cylinder factory:

Production and Processing Workshop

Loading and Unloading Robots For Paint Lines

Product Testing Center

Cylinder Composite Machining Center

Automatic Cylinder Assembly Machine

With a robust quality assurance system in place, we have achieved ISO 9001 certification for quality management, as well as ISO 45001 for occupational health and safety, and ISO 14001 for environmental management. Our efficient, standardized processes and self-developed high-end equipment guarantee that our hydraulic cylinders are durable, pressure-resistant, leak-proof, and highly stable, with performance metrics that meet international benchmarks.

The “Huachang” series hydraulic cylinders are designed with a focus on structural integrity, reliable performance, and ease of maintenance. Their diverse structural forms allow for tailored solutions to meet specific customer needs. Coupled with our digital production management system, we respond quickly and effectively to customer requirements, ensuring that we exceed your expectations.

Choose us for high-quality hydraulic solutions that enhance your machinery’s performance and reliability.

Frequently Asked Questions

Partner with us for steel mill hydraulic cylinders, furnace cylinders, and metallurgical hydraulic cylinders that deliver durability, efficiency, and value for steel mill operations. Here’s why steel mill operators and manufacturers choose us:

Proven Reliability

Our steel mill hydraulic cylinders are engineered for reliability, using high-strength steel, heat-resistant Viton seals, and corrosion-resistant coatings to withstand high-temperature, dusty steel mill conditions. Tested to ISO and DIN standards, they ensure performance in furnace tilting, continuous casting, and rolling mills.

Custom Engineering

We offer tailored custom furnace cylinders and custom metallurgical hydraulic cylinders, with bespoke bore sizes (up to 1400mm), stroke lengths, and mounting configurations. From furnace tilting to AGC applications, we meet your needs for hydraulic cylinders for steel mills.

Fast Delivery

Streamlined production ensures quick delivery of steel mill hydraulic cylinders, minimizing delays in critical steel mill operations. We keep your production on schedule.

Competitive Pricing

We provide cost-effective metallurgical hydraulic cylinders without compromising quality. Optimized production and high-quality materials ensure affordability for steel smelting, rolling, and casting applications.

Expert Support

Our 24/7 technical assistance supports installation, operation, and hydraulic cylinder repair and troubleshooting for steel mills. Certified experts ensure your furnace cylinders and metallurgical hydraulic cylinders run smoothly.

Frequently Asked Questions

Answers to common questions about steel mill hydraulic cylinders, furnace cylinders, and metallurgical hydraulic cylinders, helping steel mill operators and engineers understand durability, customization, and maintenance.

Our steel mill hydraulic cylinders feature high-strength steel, heat-resistant Viton seals, and corrosion-resistant coatings, ensuring performance in high-temperature (>100°C), dusty steel mill environments. Low-friction seals (e.g., Hunger DFE) and robust rods resist wear, extending the lifespan of furnace cylinders and metallurgical hydraulic cylinders.

Yes, we offer custom furnace cylinders tailored for furnace tilting, with bespoke bore sizes (up to 800mm), stroke lengths, and mounting configurations (e.g., flange, earring). Our custom metallurgical hydraulic cylinders meet specific continuous casting or AGC requirements, ensuring compatibility with hydraulic cylinders for steel mills.

Follow our steel mill hydraulic cylinder maintenance guide: inspect seals and rods quarterly for dust or heat damage, clean with a low-pressure washer, lubricate with high-temperature grease (e.g., Shell Gadus S3 V220C), and schedule annual professional service with fluid analysis for metallurgical hydraulic cylinder reliability.