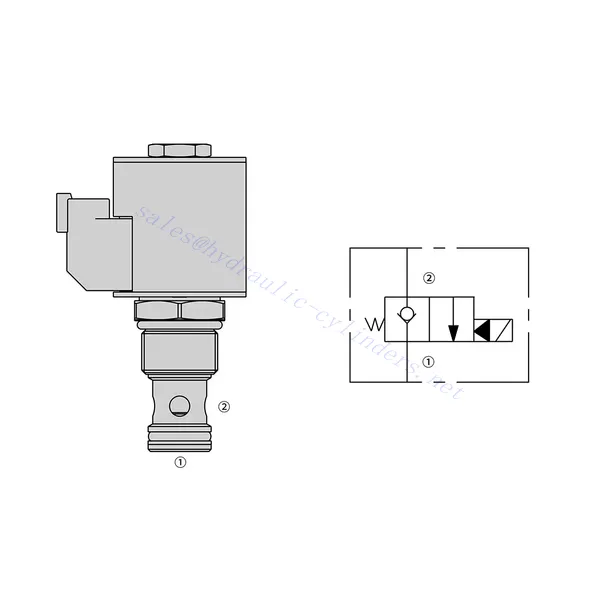

35SD12-20 Solenoid Directional Valve

Als één van de fabrikanten, de leveranciers en de exporteurs van van de hydraulische cilinders mechanische producten, bieden wij hydraulische cilinders en veel andere producten aan.

Neem contact met ons op voor meer informatie.

Mail:sales@hydraulic-cylinders.net

Fabrikant leverancier exporteur van hydraulische cilinders.

35SD12-20 Solenoid Directional Valve

The 35SD12-20 solenoid directional valve is a cutting-edge hydraulic component designed to provide precise control and efficient operation in hydraulic systems. With its advanced solenoid technology and robust construction, this valve offers a range of features and benefits that make it an essential choice for various industrial applications.

The 35SD12-20 solenoid directional valve offers precise control, durability, and versatility for efficient hydraulic systems. Its advanced solenoid technology, compact design, and customizable functionality make it an indispensable component in various industrial applications. By understanding its characteristics, proper usage methods, and maintenance requirements, users can optimize the performance and reliability of their hydraulic systems. Embrace the 35SD12-20 solenoid directional valve and experience enhanced control and efficiency in your hydraulic applications.

35SD12-20 Solenoid Directional Valve Characteristics:

- Advanced Solenoid Technology: The 35SD12-20 valve incorporates advanced solenoid technology, allowing for precise control and quick response times. This technology ensures accurate positioning and efficient operation of hydraulic actuators.

- Durable Construction: This directional valve is built with high-quality materials, ensuring durability and reliability in demanding environments. The valve body, seals, and internal components are designed to withstand high pressures and provide long-lasting performance.

- Compact and Lightweight Design: The 35SD12-20 valve features a compact and lightweight design, making it easy to install and integrate into hydraulic systems. Its small footprint allows for space-saving installations without compromising performance.

- Versatile Functionality: This solenoid directional valve offers versatile functionality, including various flow control options and multiple mounting configurations. It can be customized to meet specific application requirements, providing flexibility and adaptability.

35SD12-20 Solenoid Directional Valve Parameter:

| Rated pressure | 240 bar (3500 psi) | |

| Peak flow | See performance chart | |

| Internal Leakage | ≤3 drops/min@240bar | |

| Coil Duty Rating | Continuous from 85% to 115% of nominal voltage | |

| Initial Coil Current Draw at 20℃ | E-coil | 1.7A at 12VDC; 0.85A at 24VDC |

| D-coil | 1.67A at 12VDC; 0.83A at 24VDC | |

| Minimum pull-in voltage | 85% of nominal at 207 bar | |

| Cavity | VC12-2 | |

| Fluid | Mineral-based or synthetics with lubricating properties | |

| Fluid temperature range ℃ | -40 to 100 ℃ (Buna N seals) | |

| -26 to 204 ℃ (Fluorocarbon seals) | ||

| Viscosity range | 7.4 to 420 mm2/s | |

| Degree of contamination | The minimum pollution level is ISO4406 level 20/18/14, and level 17/15/13 is recommended to prolong the service life | |

35SD12-20 Solenoid Directional Valve Advantages:

• Continuous-duty rated coil

• Cartridges are voltage interchangeable

• Optional waterproof E-Coils rated up to IP69K

• Efficient wet-armature construction

• Industry common cavity

• Hardened parts for long life

Usage Method Of 35SD12-20 Solenoid Directional Valve:

Installation: Before installation, carefully read the manufacturer’s guidelines and ensure that the valve is compatible with the hydraulic system. Properly secure the valve using appropriate fittings and connectors, ensuring leak-free connections.

System Integration: Integrate the 35SD12-20 valve into the hydraulic system by connecting it to the main hydraulic lines. Ensure that the valve is correctly aligned and positioned for optimal performance.

Electrical Connection: Connect the solenoid valve to the electrical control system using the specified voltage and wiring configuration. Follow the manufacturer’s instructions for proper electrical connections to ensure safe and reliable operation.

Control and Operation: The 35SD12-20 valve is typically controlled by an electrical signal. Utilize a control device, such as a switch or PLC, to send signals to the valve, activating specific hydraulic functions. The valve allows for precise control of fluid direction and flow rate, enabling efficient operation of hydraulic actuators.

How To Repair Moen Shower Valve Cartridge?

Repairing a Moen shower valve cartridge can help resolve issues such as leaks, inconsistent water flow, or difficulty in adjusting the temperature. Follow these steps to repair a Moen shower valve cartridge:

- Gather the necessary tools: You will need an adjustable wrench, a flathead screwdriver, a Phillips screwdriver, a cartridge puller tool (specifically designed for Moen cartridges), and a replacement cartridge (if needed).

- Turn off the water supply: Locate the main water shut-off valve for your home and turn it off to prevent water from flowing while you work on the shower valve.

- Remove the handle and trim: Use a screwdriver or Allen wrench (depending on the type of handle) to remove the handle. Next, remove the trim plate by unscrewing any visible screws. This will expose the valve cartridge.

- Remove the cartridge: Use the cartridge puller tool to grip the cartridge and carefully pull it straight out. If the cartridge is stuck, you may need to use pliers or a cartridge removal tool provided by Moen. Make sure to follow the manufacturer’s instructions for your specific cartridge model.

- Inspect and clean the cartridge: Examine the cartridge for any damage, cracks, or mineral buildup. If the cartridge appears damaged or worn, it is recommended to replace it with a new one. If the cartridge is in good condition, clean it thoroughly with a mixture of warm water and vinegar or a mild cleaning solution. Use a soft brush to remove any debris or mineral deposits.

- Install the new cartridge: Slide the new cartridge into the valve body, making sure it aligns properly. Push it all the way in until it sits flush with the valve body.

- Reassemble the shower valve: Reattach the trim plate and secure it with the screws. Place the handle back onto the cartridge stem and tighten any screws or Allen bolts.

- Turn on the water supply: Once everything is securely reassembled, turn the main water supply back on and test the shower valve. Check for any leaks, and ensure that the water flow and temperature adjustments are functioning correctly.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: