Replacement Of AHC10282 Hydraulic Cylinder

Als één van de fabrikanten, de leveranciers en de exporteurs van van de hydraulische cilinders mechanische producten, bieden wij hydraulische cilinders en veel andere producten aan.

Neem contact met ons op voor meer informatie.

Mail:sales@hydraulic-cylinders.net

Fabrikant leverancier exporteur van hydraulische cilinders.

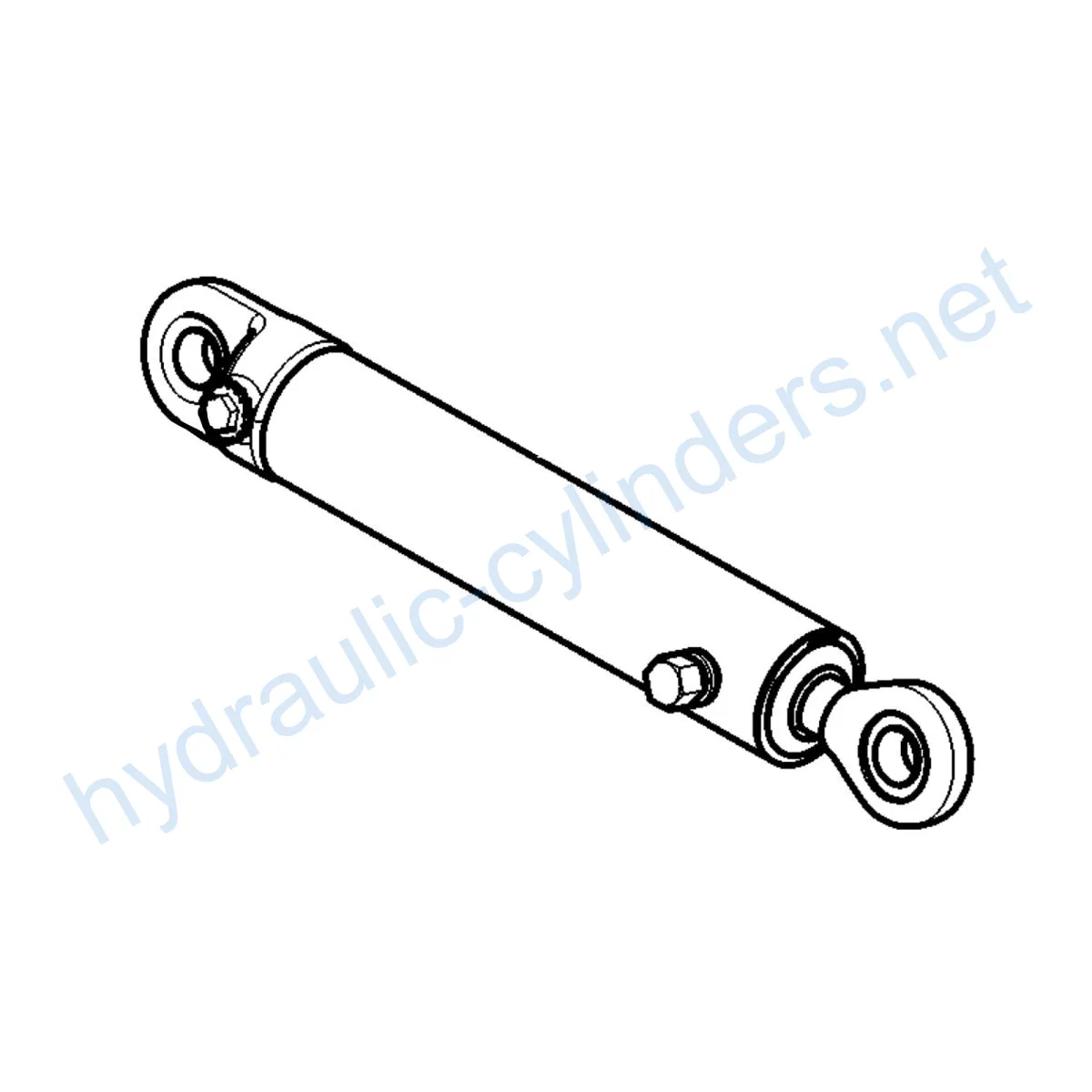

Replacement Of AHC10282 Hydraulic Cylinder

The Replacement Of AHC10282 Hydraulic Cylinder is a vital component used in various models of S7 700, S7 800, S7 850, S7 900, S670, S670 PRECISION UPGRADES, S670H, S680, S680H, S685, S685H, S690, S690 PRECISION UPGRADES, S690H, S770, S780, S780 PRECISION UPGRADES, S785, S790, and S790 PRECISION UPGRADES. This hydraulic cylinder weighs 11.15 lb and has a height of 2.25 in, a width of 3.5 in, and a length of 18.5 in.

Introduction to the Replacement Of AHC10282 Hydraulic Cylinder

The Replacement Of AHC10282 Hydraulic Cylinder is an essential part used in various industrial applications. It is designed to provide hydraulic power and mechanical force to enable the smooth operation of machinery. This cylinder plays a crucial role in converting fluid power into linear mechanical force, allowing for precise control and movement.

Specifications and Models

The Replacement Of AHC10282 Hydraulic Cylinder is available in different models, including S7 700, S7 800, S7 850, S7 900, S670, S670 PRECISION UPGRADES, S670H, S680, S680H, S685, S685H, S690, S690 PRECISION UPGRADES, S690H, S770, S780, S780 PRECISION UPGRADES, S785, S790, and S790 PRECISION UPGRADES. With a weight of 11.15 lb, a height of 2.25 in, a width of 3.5 in, and a length of 18.5 in, this cylinder is designed to fit specific equipment models and provide optimal performance.

Features of the Replacement Of AHC10282 Hydraulic Cylinder

- Improved Equipment Performance: Replacing damaged or worn hydraulic cylinders can restore the normal operation capability of equipment, ensuring its performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: Newly designed cylinders often include better overload protection mechanisms, enhancing safety.

- Quick Installation: Modern hydraulic cylinders are designed with easy installation and replacement in mind, reducing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts in the market.

Application Scenarios

The Replacement Of AHC10282 Hydraulic Cylinder finds application in various industries and equipment. Here are a few examples:

- Excavators: In excavators, the hydraulic cylinders in the boom or bucket may get damaged due to prolonged use or overload, requiring replacement to restore normal operation.

- Cranes: The lifting arm hydraulic cylinders in cranes are prone to wear and tear during frequent lifting and lowering processes, necessitating regular replacement for safety.

- Tractors: Hydraulic cylinders in front-end loaders of tractors may experience leaks or performance degradation during constant lifting and tilting operations, requiring replacement.

- Harvesters: The hydraulic system in harvesters operates under high pressure, and cylinders may get damaged due to fatigue, necessitating timely replacement to maintain operational efficiency.

- Automated Production Lines: Hydraulic cylinders are used to control robotic arms and other automated equipment. Cylinder failures can impact production efficiency, requiring immediate replacement.

- Die Casting Machines: In high-pressure and high-temperature environments, hydraulic cylinders may experience performance degradation. Regular replacement ensures product quality.

- Mining Equipment: Hydraulic cylinders are used for lifting and moving heavy loads in mining equipment. Due to the harsh working conditions, regular inspection and replacement are necessary to avoid equipment failures.

- Bulldozers: Wear of hydraulic cylinders in a bulldozer’s blade can lead to a decrease in pushing ability, requiring timely replacement to maintain operational efficiency.

Maintenance Tasks

Proper maintenance of the Replacement Of AHC10282 Hydraulic Cylinder is crucial to ensure its longevity and optimal performance. Here are three common maintenance tasks:

- Regular Inspection: Periodic inspections help identify any signs of damage or wear in the hydraulic cylinder. It allows for early detection of potential issues.

- Proper Lubrication: Adequate lubrication ensures smooth operation and reduces friction between moving parts, extending the lifespan of the cylinder.

- Seal Replacement and Calibration Check: Regularly replacing seals and checking the calibration of the cylinder ensures a tight and efficient hydraulic system.

During installation, it is essential to provide proper alignment guidance and recommend using suitable installation brackets to secure the cylinder. Recommended inspection, repair, and replacement procedures, along with the availability of replacement parts and rebuilding services, contribute to extending the lifespan of the Replacement Of AHC10282 Hydraulic Cylinder.

Safety Considerations and Environmental Factors

When using the Replacement Of AHC10282 Hydraulic Cylinder, safety precautions are of utmost importance. Adhering to safety measures while handling hydraulic components ensures the well-being of operators and prevents accidents. Additionally, considering environmental factors and implementing environmentally friendly practices contribute to sustainable operations.

Fault Diagnosis and Common Issues

It is crucial to diagnose and address any faults or issues promptly to minimize downtime and maintain equipment performance. Here are some common fault diagnoses and associated problems:

- Leakage: Hydraulic fluid leaks can lead to decreased performance and potential damage to other components.

- Seal Failure: Faulty seals can result in fluid leakage and reduced hydraulic system efficiency.

- Internal Damage: Internal damage to the cylinder can affect its overall performance and compromise equipment safety.

- Component Wear: Continuous use can cause wear and tear on various components, leading to decreased efficiency and potential failure.

For effective fault handling and issue resolution, providing troubleshooting tips and solutions is essential. Offering preventive measures helps minimize potential problems and ensures the longevity of the Replacement Of AHC10282 Hydraulic Cylinder.

Design Considerations and Selection Criteria

When selecting a hydraulic cylinder, various design considerations and selection criteria should be taken into account. Here are some key points to consider:

- Load

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: