HP4VG Series Axial Piston Variable Displacement Hydraulic Pump

Jako jeden z producentów, dostawców i eksporterów produktów mechanicznych, oferujemy cylindry hydrauliczne i wiele innych produktów.

Prosimy o kontakt w celu uzyskania szczegółowych informacji.

Poczta:sales@hydraulic-cylinders.net

Producent dostawca eksporter siłowników hydraulicznych.

HP4VG Series Axial Piston Variable Displacement Hydraulic Pump

The HP4VG series axial piston variable displacement hydraulic pump is a powerful and efficient solution designed to meet the demanding needs of modern hydraulic systems. With advanced technology and exceptional performance, this pump delivers precise control, superior power transmission, and optimum energy efficiency. This article will explore the key features, usage methods, and maintenance guidelines for the HP4VG series axial piston variable displacement hydraulic pump.

The HP4VG series axial piston variable displacement hydraulic pump is a powerful and efficient solution for hydraulic systems. With its variable displacement capability, high-pressure performance, and versatile applications, this pump delivers exceptional performance in diverse industries. By following the recommended usage methods and adhering to regular maintenance practices, the HP4VG series pump will continue to provide outstanding performance, contributing to the success of hydraulic systems. Harness the power and efficiency of the HP4VG series axial piston variable displacement hydraulic pump to unlock the full potential of your hydraulic system.

HP4VG Series Axial Piston Variable Displacement Hydraulic Pump Key Characteristics:

- Variable Displacement Capability: The HP4VG series pump is equipped with advanced variable displacement technology, allowing for precise adjustment of the pump’s output volume. This feature enables efficient power delivery, reducing energy consumption and enhancing overall system performance.

- High-Pressure Performance: The HP4VG series pump excels in high-pressure applications with its robust axial piston design. It delivers consistent performance under demanding conditions, ensuring reliable operation and efficient power transmission.

- Wide Range of Applications: The HP4VG series pump is highly versatile, making it suitable for various industries and applications. This pump performs exceptionally well in diverse hydraulic systems, from construction and agriculture to material handling and industrial machinery.

- Compact and Lightweight Design: The compact and lightweight design of the HP4VG series pump offers installation flexibility, especially in applications with space constraints. Its compact size allows easy integration into existing hydraulic systems without compromising performance.

HP4VG Series Axial Piston Variable Displacement Hydraulic Pump Parameter:

| Specification | 45 | 60 | 75 | 100 | 135 | 145 | 175 | 215 | 280 | |

| Displacement cc/rev | 45 | 60 | 75.6 | 100 | 135 | 145.3 | 175.4 | 215.7 | 280 | |

| Shaft speed | Rated rpm | 3300 | 3600 | 3300 | 3000 | 2850 | 2850 | 2650 | 2500 | 2400 |

| Maximum rpm | 3550 | 3900 | 3600 | 3300 | 3250 | 3000 | 2800 | 2650 | 2550 | |

| Minimum rpm | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| System pressure | Rated bar | 420 | 400 | 400 | 400 | 400 | 450 | 450 | 450 | 450 |

| Maximum bar | 450 | 450 | 450 | 450 | 450 | 500 | 500 | 500 | 500 | |

| Minimum low loop pressure (bar) (Above charge pump) |

10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | |

| Charge pump Displacement cc/rev | 8.6/11.6 | 11.6 | 17/21/27 | 28.3 | 32 | 26/39 | 47 | 60 | ||

| Charge pressure (relative to Charge pump) |

Max. (bar) | 35 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Shell pressure bar | Continuous pressure bar | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Max.(At cold start) bar | 3.0 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | |

| Suction pressure (absolute pressure) bar | Rated bar Oil viscosity ≤ 30mm2/s |

0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.5 | 0.8 |

| Maximum bar | 5 | 5 | 5 | 5 | 5 | 6 | 6 | 5 | 5 | |

| Oil viscosity mm2/s | 10-1000,Best range: 16~36 | |||||||||

| Oil temperature ℃ | -20~95 | |||||||||

| Oil cleanliness | ISO 4406 level 20/18/15 or higher | |||||||||

| Weight (excluding auxiliary flange) | 33 | 38 | 58 | 62 | 80 | 110 | 115 | 146 | 179.4 | |

| Permissible input and through-drive torques | |||||||||||

| Size | 45 | 60 | 75 | 100 | 135 | 145 | 175 | 215 | 208 | ||

| Torque at Vg max and Δp = 400 bar Nm | 287 | 255 | 477 | 636 | 859 | ||||||

| at Vg max and Δp = 450 bar Nm | 1253 | 1253 | 1540 | 2005 | |||||||

| Maximum input torque at drive shaft (Nm) | |||||||||||

| ANSIB92.1a–1976 | S0 | 1 in 15T 16/32DP | 272 | ||||||||

| S1 | 1 1/4 in 14T 12/24 DP | 552 | 602 | 650 | 650 | ||||||

| S2 | 1 3/8 in 21T 16/32 DP | 970 | 970 | 970 | |||||||

| S3 | 1 1/2 in 23T 16/32 DP | 1305 | 1305 | ||||||||

| S4 | 1 3/4 in 13T 8/16 DP | 1640 | 1640 | 1640 | 1640 | ||||||

| S5 | 2 1/4 in 17T 8/16 DP | 4070 | 4070 | 4070 | |||||||

| S6 | 27T 16/32 DP | 1830 | |||||||||

| S7 | 2 in 15T 8/16DP | 2670 | |||||||||

| DIN 5480 | T1 | W30×2×14×9g | 522 | ||||||||

| T2 | W35×2×16×9g | 912 | 912 | 912 | |||||||

| T3 | W45×2×21×9g | 2190 | |||||||||

| T4 | W50×2×24×9g | 3140 | |||||||||

| T5 | W40×2×18×9g | 1460 | 1460 | 1460 | |||||||

| T6 | W55×2×26×9gw | 4350 | 4350 | ||||||||

| Maximum through-drive torque (Nm) | 314 | 314 | 660 | 822 | 1110 | 1760 | 1760 | 2641 | 2641 | ||

HP4VG Series Axial Piston Variable Displacement Hydraulic Pump Advantages:

• The swash plate is designed with an axial piston variable pump for closed-circuit hydrostatic transmission.

• When the swash plate passes the neutral position, the flow direction of the hydraulic oil will change smoothly.

• Two pressure relief valves are installed on the high-pressure side to prevent overload.

• The built-in charge pump acts as a charge pump and control.

• The built-in low-pressure relief valve limits the maximum charge pressure.

• Brand new slewing components and bearings improve the transmission efficiency and the input speed.

• One-piece design at the rear of the shell reduces leakage points.

• Optimized shell design to reduce vibration and noise.

• Electric proportional displacement control to meet the application requirements of multiple industries.

• 45° oil outlet design to optimize pipeline connection.

• Optional flush valve, directly installed on the pump body.

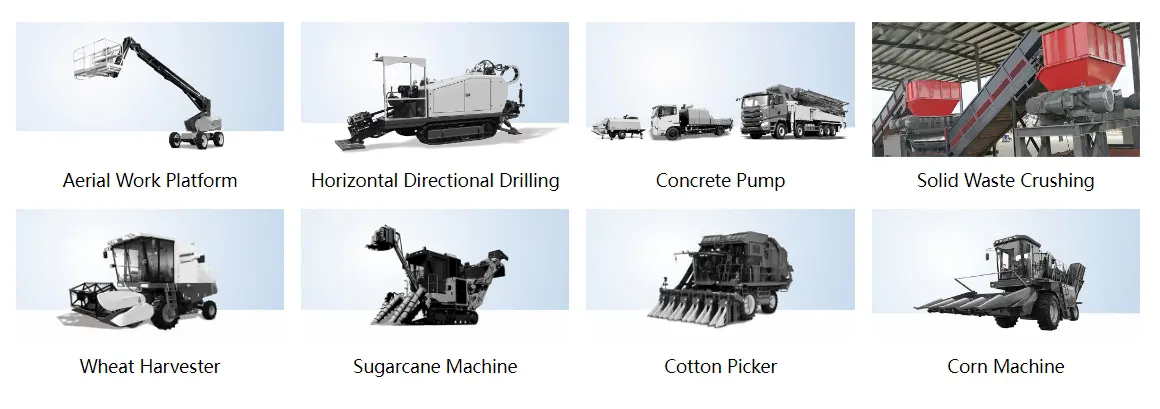

HP4VG Series Axial Piston Variable Displacement Hydraulic Pump Application:

Usage Method Of HP4VG Series Axial Piston Variable Displacement Hydraulic Pump:

- Pump Installation: Select an appropriate location in the hydraulic system to install the HP4VG series axial piston variable displacement pump. Ensure proper alignment and securely attach the pump to the system’s structure using suitable mounting brackets or accessories.

- Fluid Compatibility: Verify that the hydraulic fluid used in the system is compatible with the HP4VG series pump. Refer to the manufacturer’s recommendations for the appropriate fluid type, viscosity, and temperature range. Regularly monitor and maintain the hydraulic fluid to ensure proper pump operation and longevity.

- Integration with Hydraulic System: Connect the pump to the hydraulic system using compatible hoses, fittings, and valves. Ensure all connections are secure, leak-free, and adequately tightened for optimal hydraulic performance.

- Operational Parameters: Familiarize yourself with the pump’s control options and adjust the operating parameters according to the specific requirements of the hydraulic system. Monitor and change the pump’s displacement settings to optimize performance and energy efficiency.

How To Find Seal Kit For Hydraulic Cylinder?

Finding the appropriate seal kit for a hydraulic cylinder involves a few steps. Follow this guide to help you locate the suitable seal kit for your specific hydraulic cylinder:

- Gather Information: Before starting your search, gather essential information about the hydraulic cylinder. This includes the cylinder’s make, model, and any identifying serial numbers or part numbers. Note down the dimensions of the cylinder, such as the bore diameter, rod diameter, and stroke length. Having these details readily available will make finding the correct seal kit easier.

- Manufacturer’s Resources: Begin your search by checking the manufacturer’s resources. Visit the manufacturer’s website or contact customer support to explore if they offer seal kits specifically designed for your hydraulic cylinder. Many manufacturers provide detailed product catalogs, parts lists, or online search tools to help customers find the appropriate seal kits.

- Online Suppliers: Look for reputable suppliers specializing in hydraulic seals and seal kits. Use search engines or online marketplaces to find suppliers that offer a wide range of hydraulic seal kits. Some popular suppliers include hydraulic component distributors, industrial supply companies, and specialized hydraulic seal manufacturers. Make sure to filter your search results based on your cylinder’s make, model, and dimensions to narrow down the options.

- Seal Kit Specifications: Once you identify potential seal kits, review their specifications and compare them to the information you gathered about your hydraulic cylinder. Check if the seal kit includes all the necessary seals, such as rod seals, piston seals, and gland seals. Verify that the dimensions and specifications of the seals match those of your cylinder.

- Cross-Reference Guides: Some suppliers or manufacturers provide cross-reference guides or compatibility charts to assist in finding the right seal kit. These guides allow you to match your cylinder’s part numbers or specifications with the corresponding seal kit. Consult these resources if available to ensure an accurate match.

- Seek Expert Advice: If you’re having difficulty finding the appropriate seal kit, consider seeking advice from hydraulic experts or technicians. They possess extensive knowledge and experience in hydraulic systems and can guide you in selecting the correct seal kit for your specific cylinder. Local hydraulic repair shops, distributors, or manufacturers’ technical support teams can be valuable resources.

- Custom Seal Manufacturing: In some instances, finding a seal kit that precisely matches your hydraulic cylinder’s specifications may be challenging. In such situations, you might consider contacting specialized seal manufacturers who offer custom seal manufacturing services. They can create seals tailored to your cylinder’s unique requirements.

Możliwości i pojemność fabryki:

(1) Montaż

Dysponujemy najwyższej klasy niezależną platformą badawczo-rozwojową. Warsztat produkcji siłowników hydraulicznych posiada cztery półautomatyczne linie montażowe siłowników podnoszących i jedną automatyczną linię montażową siłowników przechyłu, o projektowanej rocznej zdolności produkcyjnej 1 miliona sztuk. Specjalny warsztat cylindrów jest wyposażony w różne specyfikacje półautomatycznego systemu montażu czyszczącego o projektowanej rocznej zdolności produkcyjnej 200 000 i wyposażony w słynny sprzęt do obróbki CNC, centrum obróbcze, specjalny sprzęt do precyzyjnej obróbki cylindrów, robot spawalniczy, automatyczna maszyna czyszcząca, automatyczna maszyna do montażu cylindrów i automatyczna linia produkcyjna do malowania. Istniejący krytyczny sprzęt składa się z ponad 300 zestawów. Optymalna alokacja i efektywne wykorzystanie zasobów sprzętowych zapewniają wymagania dotyczące dokładności produktów i spełniają potrzeby wysokiej jakości produktów.

(2) Obróbka

Warsztat obróbki skrawaniem jest wyposażony w niestandardowe centrum tokarskie z pochyloną szyną, centrum obróbcze, szybkobieżną honownicę, robota spawalniczego i inny powiązany sprzęt, który może obsługiwać przetwarzanie rur cylindrycznych o maksymalnej średnicy wewnętrznej 400 mm i maksymalnej długości 6 metrów.

(3) Spawanie

(4) Malowanie i powlekanie

Z małymi i średnimi automatycznymi liniami do powlekania farbami na bazie wody, w celu osiągnięcia automatycznego załadunku i rozładunku robota oraz automatycznego natryskiwania, wydajność projektowa 4000 sztuk na zmianę;

Posiadamy również półautomatyczną linię do produkcji farb do dużych cylindrów napędzaną łańcuchem napędowym, o wydajności 60 skrzyń na zmianę.

(5) Testowanie

Dysponujemy najwyższej klasy urządzeniami kontrolnymi i stanowiskami testowymi, aby zapewnić, że wydajność cylindra spełnia wymagania.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding przekładnie rolnicze. Eksportowaliśmy nasze produkty do klientów na całym świecie i zdobyliśmy dobrą reputację dzięki najwyższej jakości produktów i usług posprzedażnych. Zapraszamy klientów w kraju i za granicą do kontaktu z nami w celu negocjacji biznesowych, wymiany informacji i współpracować z nami!

Zapraszamy na wycieczkę po naszej fabryce VR:

Wybierz się na wycieczkę po naszej fabryce VR z następującymi elementami

Siłownik hydrauliczny Zastosowanie: