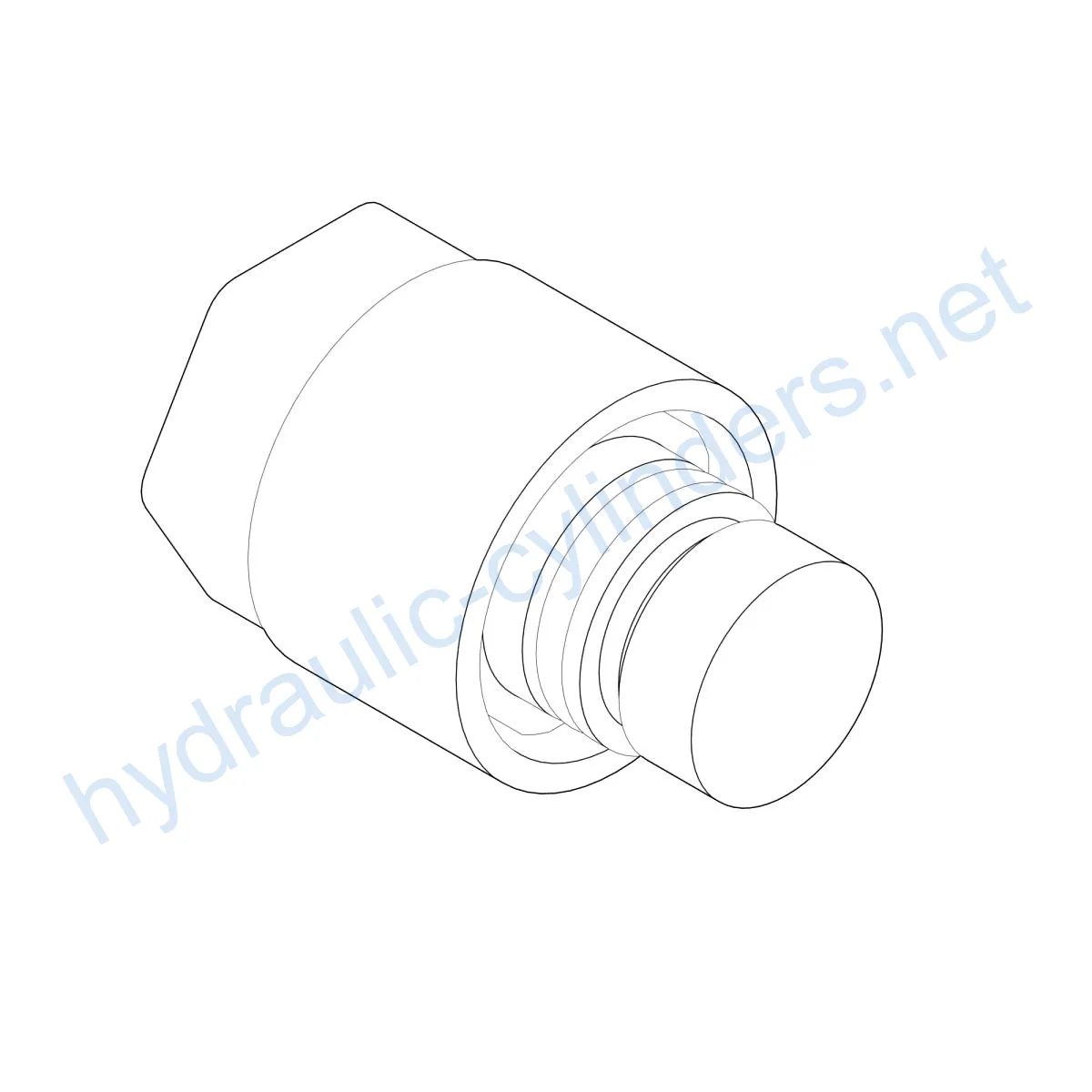

Replacement Of AT178930 Hydraulic Cylinder Port

Jako jeden z producentów, dostawców i eksporterów produktów mechanicznych, oferujemy cylindry hydrauliczne i wiele innych produktów.

Prosimy o kontakt w celu uzyskania szczegółowych informacji.

Poczta:sales@hydraulic-cylinders.net

Producent dostawca eksporter siłowników hydraulicznych.

Replacement Of AT178930 Hydraulic Cylinder Port

Replacement Of AT178930 Hydraulic Cylinder Port is a hydraulic cylinder designed to replace the original AT178930 port. It is a vital component in various models of machinery, including 310G, 310J, 310L, 310SG, 310SJ, 310SL, 310SL HL, 310TJ, 315J, 315SG, 315SL, 317, 320, 325, 325J, 328, 332, 410G, 410J, 410L, 670C, 670C II, 670CH, 670CH II, 672CH, 710G, 710J, 770C, 770C II, 770CH, 770CH II, 772CH, 772CH II, CT322, and CT332.

Product Specifications

- Weight: 0.03 lb

- Height: 0.7 in

- Width: 3.5 in

- Length: 5.7 in

Product Features

- Improved Equipment Performance: Replacing damaged or worn hydraulic cylinders can restore the normal operational capabilities of the equipment, ensuring its performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: New cylinder designs often incorporate better overload protection mechanisms, improving safety.

- Quick Installation: Modern hydraulic cylinders are designed with easy installation and replacement in mind, reducing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts in the market.

Our company specializes in manufacturing replacement hydraulic cylinders that perfectly fit and replace the mentioned models. We offer high-quality products that meet industry standards and provide reliable performance.

Applications

Replacement Of AT178930 Hydraulic Cylinder Port finds its application in various scenarios, including:

- Excavators: Replacing damaged or worn hydraulic cylinders in the excavator’s arm or bucket can restore normal operation and functionality.

- Cranes: Crane boom hydraulic cylinders can experience wear and tear during frequent lifting and lowering operations, requiring regular replacement for safety.

- Tractors: Front-end loader hydraulic cylinders in tractors may leak or lose performance over time due to continuous lifting and tilting operations, necessitating replacement.

- Harvesters: Hydraulic cylinders in harvesting equipment are subjected to high pressure during the harvesting process. Regular replacement ensures efficient operation.

- Automated Production Lines: Hydraulic cylinders are used to control robotic arms and other automated equipment. Timely replacement is crucial to maintain production efficiency.

These applications showcase the versatility and importance of Replacement Of AT178930 Hydraulic Cylinder Port in various industries.

Maintenance Tasks

Regular maintenance tasks for Replacement Of AT178930 Hydraulic Cylinder Port include:

- Regular Inspection: Inspecting the hydraulic cylinder for any signs of damage or wear ensures early detection of potential issues.

- Proper Lubrication: Adequate lubrication of the cylinder’s components helps reduce friction and prolong its lifespan.

- Seal Replacement and Calibration Check: Periodically replacing worn seals and checking the calibration of the cylinder ensures optimal performance.

Proper installation, lubrication, and adjustment are crucial for the reliable operation of Replacement Of AT178930 Hydraulic Cylinder Port. Providing alignment guidance during installation and recommending the use of appropriate mounting brackets to secure the cylinder are essential.

Our company offers inspection, repair, and replacement services to enhance the lifespan of the hydraulic cylinder. We provide high-quality replacement parts and rebuilding services to meet the specific needs of our customers.

Safety Considerations and Environmental Factors

When using Replacement Of AT178930 Hydraulic Cylinder Port, it is important to prioritize safety measures. Ensuring the proper use of safety equipment and following recommended procedures minimizes the risk of accidents or injuries.

Environmental factors should also be taken into account when operating hydraulic cylinders. Proper disposal of used hydraulic fluids and adherence to environmental regulations contribute to a sustainable and eco-friendly approach.

Troubleshooting and Common Issues

When troubleshooting hydraulic cylinder issues, it is important to consider the following common problems:

- Leakage: Check for any signs of hydraulic fluid leakage, which may indicate a faulty seal or damaged component.

- Slow or Inconsistent Operation: If the cylinder operates slowly or exhibits inconsistent movement, it may be due to insufficient lubrication or internal wear.

- Excessive Noise or Vibrations: Unusual noise or vibrations during operation may indicate misalignment, worn components, or an issue with the mounting.

To address these issues, it is recommended to inspect the cylinder thoroughly, replace any damaged parts, and ensure proper lubrication. Performing regular maintenance tasks and adopting preventive measures can minimize potential problems.

Design Considerations and Selection Criteria

When selecting Replacement Of AT178930 Hydraulic Cylinder Port, it is important to consider the following design considerations:

- Load-Bearing Capacity: Ensure that the hydraulic cylinder can handle the intended workload without compromising performance.

- Sealing Performance: Optimal sealing properties are crucial to prevent leaks and maintain efficient operation.

- Durability: The cylinder should be constructed with durable materials to withstand various operating conditions and ensure a long lifespan.

- Safety: The design should incorporate safety features to prevent accidents and ensure operator protection.

- Maintainability: Easy access for maintenance and repair, as well as the availability of replacement parts, contribute to the cylinder’s overall performance.

Replacement Of AT178930 Hydraulic Cylinder Port utilizes various sealing components such as piston seals and rod seals, which are made of wear-resistant materials like polyurethane and nitrile rubber. The cylinder body and threaded ends are precisely treated to enhance wear resistance. Regular lubrication with appropriate hydraulic oil is necessary to ensure smooth operation.

Regular Inspection and Preventive Maintenance

To maintain optimal performance, it is essential to perform regular inspections and preventive maintenance tasks on Replacement Of AT178930 Hydraulic Cylinder Port. These tasks include:

- Inspecting the cylinder for any

Zapraszamy na wycieczkę po naszej fabryce VR:

Wybierz się na wycieczkę po naszej fabryce VR z następującymi elementami

Siłownik hydrauliczny Zastosowanie: