CB Light Tie Rod Hydraulic Cylinder with Pin

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

CB Light Tie Rod Hydraulic Cylinder with Pin

The CB Light Tie Rod Hydraulic Cylinder with Pin is a cutting-edge solution that delivers exceptional performance and versatility across various industrial applications. Featuring a unique pin design and lightweight construction, this hydraulic cylinder ensures precise linear motion control and enhances operational efficiency. Whether deployed in manufacturing equipment, construction machinery, or material handling systems, the CB Light Tie Rod Hydraulic Cylinder with Pin is a reliable choice for optimizing productivity and ensuring seamless operations.

Key Features of the CB Light Tie Rod Hydraulic Cylinder with Pin:

- Innovative Pin Design: Our cylinder incorporates a user-friendly pin design that simplifies installation and disassembly. These pins create a secure connection between the cylinder and the mounting structure, maximizing stability and minimizing the risk of misalignment during operation.

- Lightweight Construction: The light tie rod structure utilizes advanced materials, such as aluminum or composite piston rods, significantly reducing the overall weight of the cylinder. This lightweight design not only enables faster movement but also enhances energy efficiency, ultimately lowering operating costs.

- Precision in Motion: The CB Light Tie Rod Hydraulic Cylinder with Pin is engineered for exact linear motion control. It guarantees accurate positioning, smooth operation, and outstanding repeatability—making it the perfect choice for applications that demand high precision and reliability.

CB Light Tie Rod Hydraulic Cylinder with Pin Parameter:

Bolt Outline Installation Dimension Drawing:

CB Light Tie Rod Hydraulic Cylinder with Pin Usage Method:

Mounting: Attach the cylinder to the mounting structure using the supplied pins. During operation, ensure that the pins are inserted correctly and securely to prevent movement or misalignment.

Hydraulic Connection: Connect the hydraulic line to the designated port on the cylinder, ensuring proper alignment and securing of the joint to prevent leakage. Follow the guidelines for hydraulic systems and consult the manufacturer’s instructions for appropriate hydraulic connections.

Power Supply: Connect the light tie rod hydraulic cylinder to a reliable power source, such as a pump or power unit, through appropriate hydraulic lines. Ensure that the power supply complies with cylinder specifications and operating requirements.

Control And Test: Use the control valve to regulate the flow of hydraulic oil to and from the cylinder. The movement of the cylinder is tested by starting the hydraulic system and observing the linear trend. Ensure the cylinder runs smoothly and accurately without abnormal sound or vibration.

CB Light Tie Rod Hydraulic Cylinder with Pin Maintenance:

Regular maintenance is crucial to ensure optimal performance and prolong the lifespan of the CB With Pin Light Tie Rod Hydraulic Cylinder’s lifespan. Here are some maintenance guidelines:

- Regular Inspections: Check the cylinder regularly for signs of wear, damage, or leaks. Check pins, seals, tie rods, and other components for abnormalities. Resolve any issues promptly to prevent further injury or operational inefficiencies.

- Lubrication: Apply the recommended lubricant to the moving parts of the cylinder, including tie rods and seals. Regular lubrication minimizes friction, reduces wear, and ensures smooth operation: proper lubrication interval and lubricant type by manufacturer’s guidelines.

- Seal Replacement: If seals are found to be deteriorating or leaking, replace seals with genuine parts approved by the manufacturer. Incorrect or worn seals can compromise cylinder performance and lead to hydraulic oil leakage.

- Cleaning: Clean light tie rod hydraulic cylinders by removing dirt, debris, and other contaminants. Before reassembling, use a non-abrasive cleaner and make sure all parts are arid. A clean cylinder promotes optimal performance and prevents premature wear or damage.

How To Disassemble A Hydraulic Cylinder?

Disassembling a hydraulic cylinder requires careful attention and adherence to proper procedures to ensure safe and effective disassembly. Here is a general guide on how to disassemble a hydraulic cylinder:

- Safety Precautions: Before beginning the disassembly process, ensure the hydraulic system is depressurized and the equipment is securely stabilized to prevent accidental movement or injury. Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses.

- Identify the Cylinder: Familiarize yourself with the specific type and model of hydraulic cylinder you are working on. Refer to the manufacturer’s documentation or technical specifications for disassembly instructions or precautions.

- Drain Hydraulic Fluid: Position a suitable container beneath the cylinder to catch any hydraulic fluid draining during disassembly. Loosen the fittings or plugs on the cylinder to allow the liquid to drain completely.

- Secure the Cylinder: Use appropriate clamps or fixtures to hold the cylinder securely during disassembly. This ensures stability and prevents any accidental movement or damage.

- Remove External Components: Remove any external components attached to the cylinder, such as mounting brackets, end caps, or covers. Use the appropriate tools, such as wrenches or sockets, to loosen and remove fasteners or retaining bolts.

- Disassemble the Head and Cap: Carefully remove the head and cap of the cylinder. Depending on the cylinder design, these may be secured by bolts or threaded connections. Loosen the fasteners or unscrew the links, not damaging any sealing surfaces.

- Extract the Piston and Tie Rod: Once the head and cap are removed, the piston and tie rod assembly can be extracted from the cylinder barrel. Slowly and evenly push or pull the piston and tie rod out of the barrel, ensuring it remains aligned and does not bind or get stuck.

- Inspect and Clean Components: Inspect all disassembled components for signs of wear, damage, or contamination. Clean the parts using an appropriate solvent or cleaner to remove dirt, debris, or hydraulic fluid residue. Use lint-free cloths or brushes for cleaning.

- Replace Seals and Worn Parts: If any seals or other components show signs of wear or damage, replace them with genuine manufacturer-approved parts. Ensure that the replacement parts match the specifications of the original features.

- Reassembly or Further Maintenance: If you are conducting maintenance or repairs on specific cylinder components, follow the appropriate procedures. Otherwise, reverse the disassembly steps if you need to reassemble the cylinder, ensuring all members are properly aligned and tightened according to the manufacturer’s specifications.

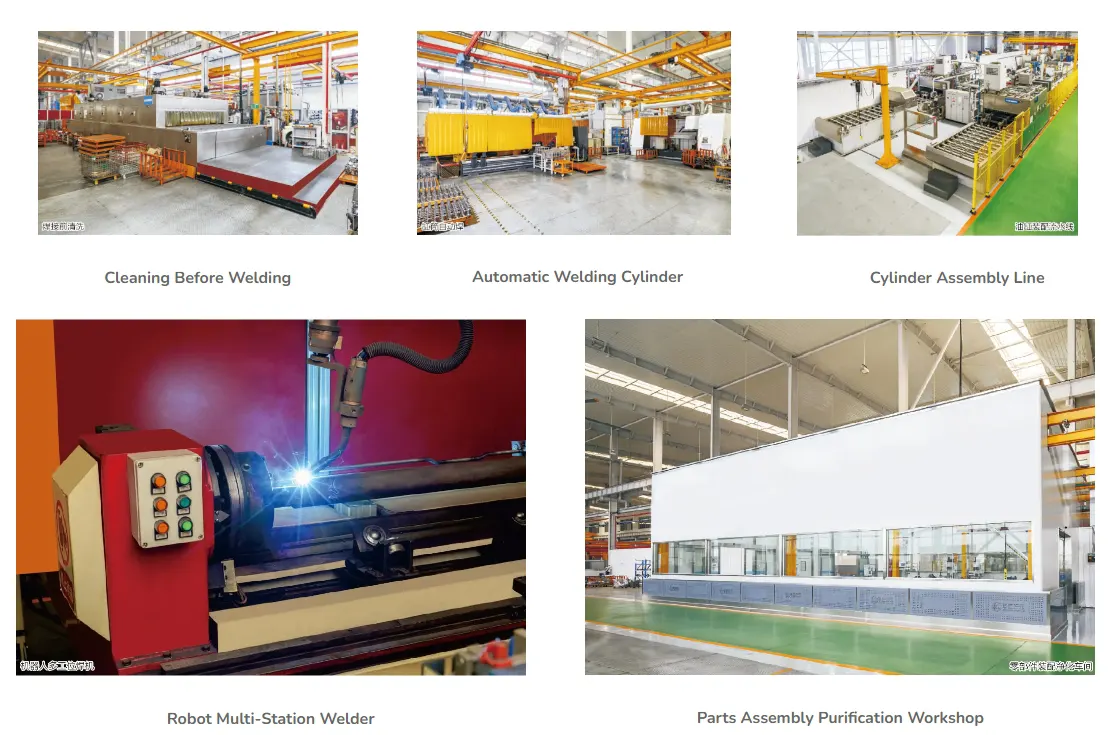

Capability & Capacity Of Factory:

(1) Assembly

Our facility boasts a top-tier independent research and development assembly platform dedicated to hydraulic cylinder production. We operate four semi-automatic lifting cylinder assembly lines and one fully automatic tilt cylinder assembly line, with an impressive annual production capacity of 1 million cylinders.

In our specialized cylinder workshop, we utilize a semi-automatic cleaning assembly system designed for various specifications, capable of producing 200,000 cylinders annually. Our workshop is equipped with advanced CNC machining equipment, a machining center, high-precision cylinder processing tools, robot welding machines, automatic cleaning systems, and an automated cylinder assembly line. Additionally, we have a fully automated painting production line.

With over 300 pieces of critical equipment, our optimal resource allocation ensures that we meet the strict accuracy and quality standards required by our clients. This commitment to efficiency and precision positions us as a leader in the hydraulic cylinder industry.

(2) Machining

Our machining shop features state-of-the-art equipment, including a customized inclined rail turning center, a precision machining center, a high-speed honing machine, and advanced welding robots. This sophisticated setup enables us to efficiently process cylinder tubes with a maximum inner diameter of 400mm and a length of up to 6 meters.

With our cutting-edge technology, we ensure high-quality machining that meets the diverse needs of hydraulic cylinder production.

(3) Welding

(4) Painting & Coating

Our facility features advanced automatic water-based paint coating lines specifically designed for small and medium-sized cylinders. These lines utilize robotic technology for efficient loading, unloading, and spraying, achieving a remarkable production capacity of 4,000 pieces per shift.

In addition, we operate a semi-automatic paint production line for large cylinders, powered by a robust power chain, with a designed capacity of 60 cases per shift. This combination of automation and efficiency ensures high-quality finishes for all our hydraulic cylinders.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are a renowned manufacturer of hydraulic cylinders, recognized as one of the best in the industry. Our extensive product line includes a wide range of hydraulic cylinders tailored to meet various applications. In addition to hydraulic cylinders, we also provide high-quality agricultural gearboxes, ensuring our customers have access to comprehensive solutions for their machinery needs.

With a commitment to excellence, we have successfully exported our products to clients worldwide, earning a strong reputation for superior product quality and exceptional after-sales service. Our dedication to customer satisfaction has positioned us as a trusted partner in both domestic and international markets.

Why Choose the CB Light Tie Rod Hydraulic Cylinder?

- Enhanced Performance: The CB Light Tie Rod Hydraulic Cylinder is designed for optimal performance, providing smooth and efficient operation in various applications.

- Cost-Effective Solution: With its durability and low maintenance requirements, this hydraulic cylinder offers a cost-effective solution for businesses looking to improve their hydraulic systems.

- Availability: You can easily find the CB Light Tie Rod Hydraulic Cylinder for sale through various suppliers, ensuring you can acquire this essential component when needed.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: