Forklift Lift Cylinder Main Lift Cylinder On Forklift

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

Forklift Lift Cylinder Main Lift Cylinder On Forklift

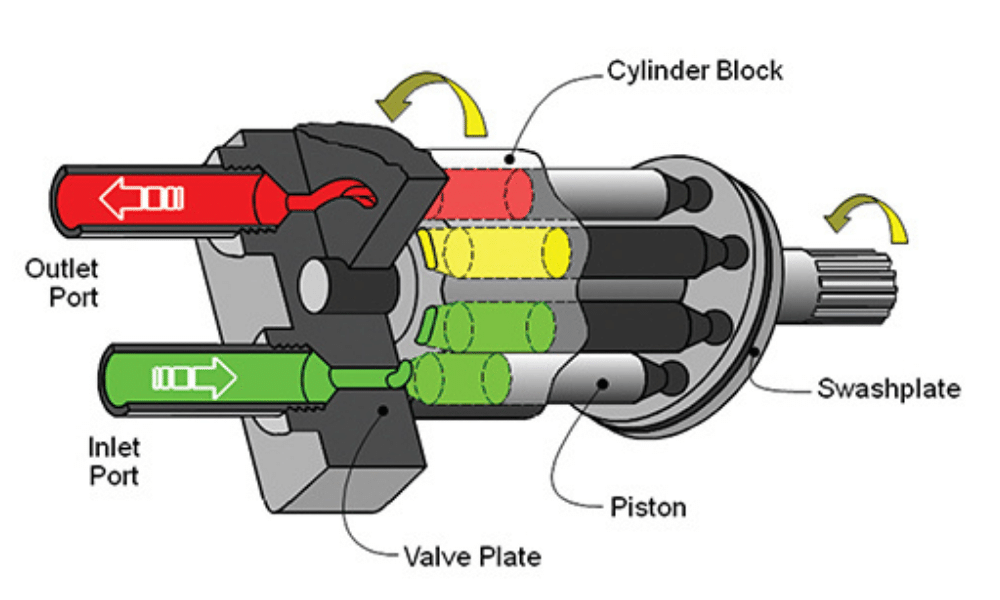

A forklift hydraulic lift cylinder is an essential component for lifting the forklift fork, playing a vital role in the overall functionality of the machine. This forklift main lift cylinder operates as a single-acting cylinder, meaning it works in one direction. Hydraulic oil is pumped in to extend the piston, effectively lifting the fork to elevate loads. When the hydraulic fluid is released, the piston retracts, lowering the fork back down.

Typically constructed from durable steel, the forklift hydraulic lift cylinder features a hardened steel piston rod and a reliable piston seal designed to prevent hydraulic oil leakage. This robust construction ensures longevity and optimal performance under various operating conditions.

The size and capacity of the forklift main lift cylinder can vary significantly based on the type of forklift and the weight of the load it is engineered to lift. For example, a small forklift intended for lighter loads will have a smaller hydraulic lift cylinder, while a larger forklift designed for heavier loads will be equipped with a more substantial cylinder.

Understanding the specifications and capabilities of your forklift hydraulic lift cylinder is crucial for safe and efficient operation. This component enables operators to lift and lower loads with precision, which is vital for various industrial applications from warehousing to construction sites.

Forklift Lift Cylinder Parameter:

| Cylinder Name | drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| Lifting cylinder | N30M300-5/400000-000 | Φ56 | Φ45 | 1500 | 1658 | 18.1MPa | G1/2 | 32.6kg |

| Lifting cylinder | A2A30M300-400000-000 | Φ56 | Φ45 | 1500 | 1658 | 18.1MPa | M22*1.5 | 36kg |

| Lifting cylinder | 3.5N4.5H-400000-003 | Φ60 | Φ45 | 1505 | 1780 | 17.5MPa | M22*1.5 | 41kg |

| Lifting cylinder | N35M300-5/400000-001A | Φ60 | Φ45 | 1500 | 1808 | 18.1MPa | G1/2 | 46kg |

| Lifting cylinder | A2A35M300-400000-000 | Φ60 | Φ45 | 1500 | 1808 | 18.1MPa | M22*1.5 | 50kg |

Key Features and Characteristics Of Forklift Lifting Hydraulic Cylinder:

Robust Construction: The forklift lift cylinder features a strong design that can withstand high pressures and heavy loads. Made from durable materials, it ensures longevity and reliability, even in demanding environments. This cylinder is engineered for consistent performance, making it a valuable asset in various applications.

Precision Control: With exceptional precision, the forklift lift cylinder allows accurate movement and force control. Whether lifting, pushing, pulling, or rotating, this cylinder provides smooth and precise operation, ensuring optimal performance and productivity.

Versatile Application: The forklift lift cylinder is used across multiple industries, including construction, manufacturing, agriculture, and more. This versatile device handles a wide range of tasks, from operating heavy machinery to powering hydraulic presses, making it an indispensable component of hydraulic systems.

Main Lift Cylinder On Forklift Application:

What Are The Common Causes Of A Forklift Lift Cylinder Leaking?

Certainly! Here’s a more detailed exploration of the common causes of a forklift lift cylinder leaking:

1. Worn Seals

Material Degradation: Seals are typically made of rubber or other elastomers that can degrade over time due to heat, pressure, and hydraulic fluid exposure. This degradation can lead to cracks or hardening, compromising their sealing ability.

Environmental Factors: Exposure to extreme temperatures, UV light, or harsh chemicals can accelerate seal wear, increasing the likelihood of leaks.

2. Damaged Cylinder Rod

Surface Imperfections: Any scratches, nicks, or corrosion on the cylinder rod can create a pathway for hydraulic fluid to escape. These imperfections can occur from improper handling, contact with debris, or general wear.

Rod Misalignment: If the cylinder rod is not aligned correctly, it can cause uneven wear on the seals, leading to premature failure and leaks.

3. Loose Fittings

Vibration and Movement: Forklifts are subjected to constant vibrations and movements, which can loosen hydraulic fittings over time. Regular checks are necessary to ensure all connections are secure.

Installation Issues: If fittings were not installed correctly during maintenance or repair, they may become loose and lead to leaks.

4. Overpressure

Hydraulic System Issues: If the hydraulic system is overpressurized due to malfunctioning components or improper adjustments, it can put excessive stress on seals and fittings, resulting in leaks.

Pressure Relief Valve Failure: A malfunctioning pressure relief valve can fail to regulate the system pressure, leading to increased stress on the lift cylinder.

5. Contamination

Debris in Hydraulic Fluid: Dirt, metal shavings, or other contaminants in the hydraulic fluid can damage seals and cause leaks. Regular fluid changes and filtration can help mitigate this issue.

Water Contamination: Water entering the hydraulic system can lead to rust and corrosion, further damaging seals and components.

6. Age and Wear

Lifecycle of Components: As hydraulic systems age, components naturally wear out. Older forklifts or those with heavy use are more prone to leaks due to general wear and tear.

Fatigue of Materials: Repeated cycles of pressurization and depressurization can lead to material fatigue, resulting in failures in seals and other components.

7. Improper Maintenance

Neglecting Regular Checks: Failing to inspect and maintain the hydraulic system can lead to undetected wear and leaks. Scheduled maintenance is essential for identifying potential issues before they escalate.

Use of Incorrect Fluids: Using hydraulic fluids that do not meet manufacturer specifications can lead to seal damage and increased wear on hydraulic components.

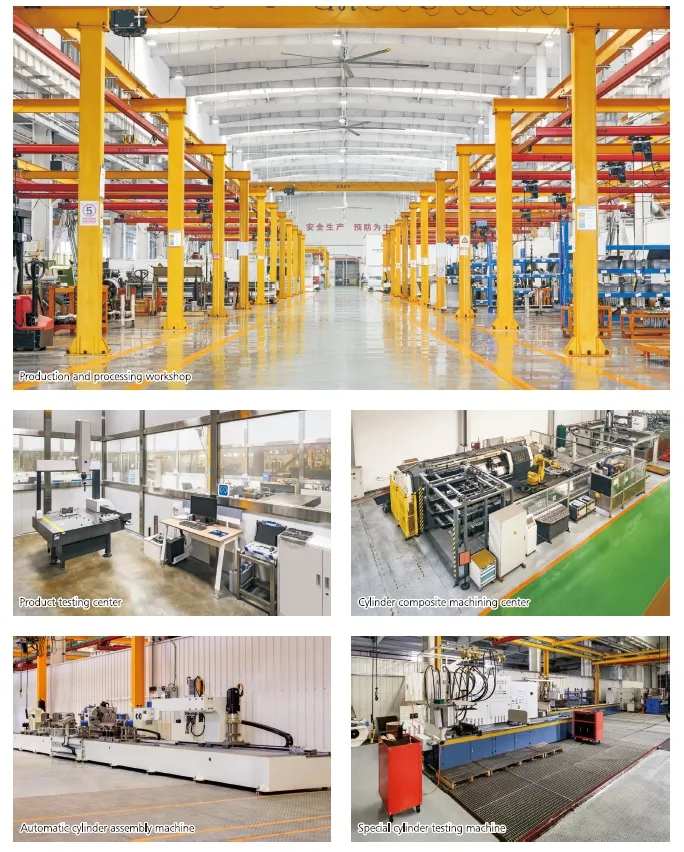

Capability & Capacity Of Factory:

(1) Assembly

Our facility boasts a top-tier independent research and development assembly platform dedicated to hydraulic cylinder production. We operate four semi-automatic lifting cylinder assembly lines and one fully automatic tilt cylinder assembly line, with an impressive annual production capacity of 1 million cylinders.

In our specialized cylinder workshop, we utilize a semi-automatic cleaning assembly system designed for various specifications, capable of producing 200,000 cylinders annually. Our workshop is equipped with advanced CNC machining equipment, a machining center, high-precision cylinder processing tools, robot welding machines, automatic cleaning systems, and an automated cylinder assembly line. Additionally, we have a fully automated painting production line.

With over 300 pieces of critical equipment, our optimal resource allocation ensures that we meet the strict accuracy and quality standards required by our clients. This commitment to efficiency and precision positions us as a leader in the hydraulic cylinder industry.

(2) Machining

Our machining shop features state-of-the-art equipment, including a customized inclined rail turning center, a precision machining center, a high-speed honing machine, and advanced welding robots. This sophisticated setup enables us to efficiently process cylinder tubes with a maximum inner diameter of 400mm and a length of up to 6 meters.

With our cutting-edge technology, we ensure high-quality machining that meets the diverse needs of hydraulic cylinder production.

(3) Welding

(4) Painting & Coating

Our facility features advanced automatic water-based paint coating lines specifically designed for small and medium-sized cylinders. These lines utilize robotic technology for efficient loading, unloading, and spraying, achieving a remarkable production capacity of 4,000 pieces per shift.

In addition, we operate a semi-automatic paint production line for large cylinders, powered by a robust power chain, with a designed capacity of 60 cases per shift. This combination of automation and efficiency ensures high-quality finishes for all our hydraulic cylinders.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are a renowned manufacturer of hydraulic cylinders, recognized as one of the best in the industry. Our extensive product line includes a wide range of hydraulic cylinders tailored to meet various applications. In addition to hydraulic cylinders, we also provide high-quality agricultural gearboxes, ensuring our customers have access to comprehensive solutions for their machinery needs.

With a commitment to excellence, we have successfully exported our products to clients worldwide, earning a strong reputation for superior product quality and exceptional after-sales service. Our dedication to customer satisfaction has positioned us as a trusted partner in both domestic and international markets.

Forklift Main Lift Cylinder Manufacturer:

Why Choose Us for Your Forklift Hydraulic Cylinder Needs?

1. Professional Expertise

Our dedicated team consists of industry professionals with extensive knowledge and hands-on experience in hydraulic systems. This expertise enables us to deliver top-notch forklift hydraulic cylinders and services that meet the highest standards of quality and performance. When you choose us, you’re selecting a partner committed to excellence.

2. International Certifications

We adhere to rigorous quality standards and proudly hold various international certifications. These credentials not only demonstrate our commitment to delivering reliable and safe hydraulic solutions but also provide you with peace of mind knowing that our products are built to last and perform under pressure.

3. Custom Solutions

We recognize that each customer’s needs are unique. That’s why we offer customized forklift hydraulic cylinders and gearboxes tailored to meet your specific requirements. Whether you need a specialized design or modifications for unique applications, we work closely with you to provide the perfect solution.

4. Advanced Production Equipment

Our state-of-the-art manufacturing facilities are equipped with the latest technology and equipment. This advanced production capability allows us to produce high-quality forklift hydraulic cylinders efficiently and consistently, ensuring that you receive the best products on the market.

5. Comprehensive After-Sales Support

Our commitment to our customers extends well beyond the initial sale. We provide ongoing support and maintenance services to guarantee the optimal performance of our forklift hydraulic cylinders. Our dedicated team is always available to assist you with any questions or concerns, ensuring your operations run smoothly.

Connect with Us Today!

We invite customers from around the globe to reach out for business negotiations, information exchange, and collaboration opportunities. Together, we can achieve greater success in the hydraulic industry. Contact us now to explore how our solutions can elevate your operations!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: