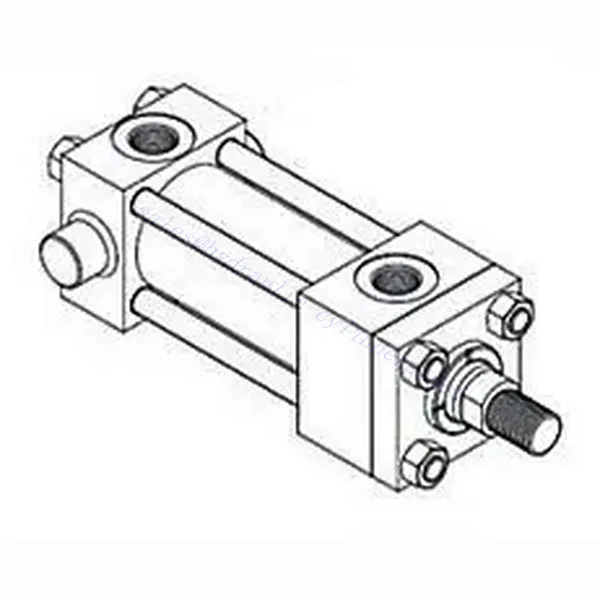

Front Cover Trunnion Four Rod Hydraulic Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

Front Cover Trunnion Four Rod Hydraulic Cylinder

The front trunnion four rod hydraulic cylinder is a high-performance hydraulic element that provides superior power, precise control, and unmatched versatility in various industrial applications. With its innovative front cover trunnion design and four-bar configuration, this four rod hydraulic cylinder offers increased stability, durability, and load-carrying capacity, making it an indispensable asset in demanding hydraulic systems.

Essential Characteristics Of Four Rod Hydraulic Cylinder:

Front Cover Trunnion Design:

-

- The front cover trunnion design provides a safe and efficient installation solution that ensures reliable operation even under heavy loads and extreme conditions.

- It simplifies installation and can be easily integrated into various hydraulic systems or equipment.

Four Rod Configuration:

-

- The four rod configuration enhances the bearing capacity of the four rod hydraulic cylinder and ensures optimal stability and precise positioning.

- It enables the four rod hydraulic cylinder to withstand side loads effectively, providing exceptional resistance to torsion and side forces.

High Power Output:

-

- This four rod hydraulic cylinder has an impressive power output, allowing it to handle heavy loads efficiently.

- It provides superior power and thrust, making it suitable for strength and lifting capacity applications.

Precise Control:

-

- The front cover trunnion four-bar hydraulic cylinder provides precise linear motion control to ensure accurate positioning and smooth operation.

- It provides excellent stroke control, enabling operators to achieve the speed and precision required for specific tasks.

Front Cover Trunnion Four Rod Hydraulic Cylinder Parameter:

Usage Method Of Front Cover Trunnion Four Rod Hydraulic Cylinder:

Mounting and Installation:

-

- Consider load requirements and space constraints to determine the appropriate installation location of the four rod hydraulic cylinder within the system or equipment.

- Ensure the mounting surface is clean, level, and can support the weight of the cylinder.

- Place the front cover trunnions flush with the mounting face and secure them using recommended bolts or fasteners.

Hydraulic Connections:

-

- Connect the hydraulic supply line to the cylinder port, ensuring proper seal to prevent leakage.

- Follow the manufacturer’s recommendations for the type of hydraulic oil and fill the system to the recommended level.

Operation:

-

- Activate the hydraulic system and control the movement of the cylinder using a hydraulic control valve or other suitable control mechanism.

- Adjust flow and pressure Settings to achieve the desired speed and force output.

- Regularly monitor four rod hydraulic cylinder operation for abnormal behavior, such as leakage, overheating, or unusual noise.

Maintenance Of Front Cover Trunnion Four Rod Hydraulic Cylinder:

Regular Inspection:

-

- Perform routine visual inspections to check for signs of wear, leakage, or damage.

- Check tie rod surfaces, seals and mounting connections for abnormalities and resolve any problems in a timely manner.

Lubrication:

-

- Follow the manufacturer’s lubrication interval guidelines and use recommended lubricants to ensure smooth operation.

- Lubricate rods, seals and other moving parts to reduce friction and extend cylinder life.

Seal Replacement:

-

- Over time, seals may wear out and need to be replaced. If a leak is detected, carefully remove the old seal and install the new seal according to the manufacturer’s specifications.

How Do You Measure A Hydraulic Cylinder?

You will need a few basic tools to measure a hydraulic cylinder, such as a tape measure, calipers, or a micrometer. Here’s a step-by-step guide on how to measure a hydraulic cylinder:

- Determine the Purpose of Measurement:

- Decide whether to measure the entire cylinder length or specific dimensions such as the rod diameter or stroke length.

- Measure the Overall Cylinder Length:

- Extend the hydraulic cylinder to its maximum length for an accurate measurement.

- Use a tape measure or ruler to measure from one end of the cylinder to the other, including any mounting brackets or clevises.

- Measure the Rod Diameter:

- If you need to measure the rod diameter, retract the cylinder fully so that the rod is completely exposed.

- Use calipers or a micrometer to measure the diameter of the rod. Place the measuring tool perpendicular to the rod’s axis and measure multiple points to ensure accuracy. Take note of the largest diameter measurement.

- Measure the Stroke Length:

- The stroke length refers to the distance the rod can travel from fully retracted to fully extended.

- Retract the cylinder completely and measure the distance from the base or mounting surface to the end of the rod.

- Measure the Bore Diameter:

- The bore diameter refers to the internal diameter of the cylinder barrel.

- If you need to measure the bore diameter, remove the cylinder from the equipment (if possible) and inspect the open end of the barrel.

- Use calipers or a micrometer to measure the internal diameter of the barrel at multiple points. Take note of the largest diameter measurement.

- Record and Verify Measurements:

- After obtaining the measurements, record them accurately for future reference.

- Double-check the measurements to ensure they are correct and consistent.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best light four rod hydraulic cylinder manufacturers. We can offer comprehensive light four rod hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: