Head Round Flange Type Metallurgical Hydraulic Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

Head Round Flange Type Metallurgical Hydraulic Cylinder

The head round flange type metallurgical hydraulic cylinder is a cutting-edge element specially designed for metallurgical applications. With its superior performance, rugged construction, and innovative design, this metallurgical hydraulic cylinder provides precise control, durability, and efficiency in demanding industrial environments. Whether used in steel mills, foundries, or other metallurgical processes, headround flange-type cylinders offer outstanding results.

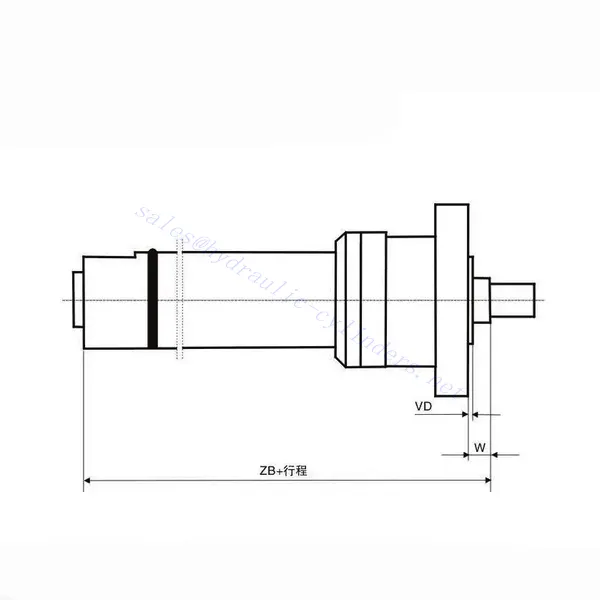

Y-HG1 series of metallurgical hydraulic cylinder for the double acting piston cylinder, cylinder diameter is generally in the range of 40~320mm, the working pressure <=16MPA, the hydraulic oil mechanical system can be used to lose emulsion and other working media, the installation of flange, earrings, pins, trippers (base) and different types.

High precision CNC honing machine, automatic welding machine, vertical, horizontal machining center, gantry machining center, CNC lathe, and other processing equipment, product quality is stable and guaranteed.

Head Round Flange Type Metallurgical Hydraulic Cylinder Parameter:

Head Round Flange Type Metallurgical Hydraulic Cylinder Usage Method:

- Mounting and Installation:

- According to the specific requirements of metallurgical equipment, determine the appropriate installation position of the hydraulic cylinder.

- Ensure that the mounting surface is clean, flat, and able to withstand the weight and load of the cylinder.

- Connection to Hydraulic System:

- Connect the metallurgical hydraulic cylinder to the hydraulic system using a compatible hydraulic hose or pipe.

- Ensure proper alignment and secure connections to prevent leaks.

- System Integration and Calibration:

- By the manufacturer’s guidelines, integrate metallurgical hydraulic cylinders into metallurgical equipment or systems.

- Calibrate the system to achieve optimal performance and desired operation parameters.

- Operating the Cylinder:

- Activate the hydraulic system to apply pressure and initiate the movement of the hydraulic cylinder.

- The hydraulic control system controls cylinder extension and precise positioning for efficient metallurgical operation.

Head Round Flange Type Metallurgical Hydraulic Cylinder Characteristics:

- Head Rectangular Flange Design: The unique rectangular flange design provides enhanced stability, precise alignment, and improved load distribution during operation, ensuring optimal performance in metallurgical processes.

- Metallurgical Application Focus: The cylinders are precisely designed to meet the demanding requirements of metallurgical applications, providing reliability and durability under extreme conditions.

- Superior Performance: Cylinders offer excellent performance, enabling accurate positioning, smooth operation, and high productivity in metallurgical processes.

- Robust Construction: Manufactured from high-quality materials, the cylinders can withstand heavy loads and harsh operating conditions, ensuring long-term durability and reliable performance.

- Safety Features: The design combines overload protection and an emergency shutdown mechanism, prioritizing operator safety in the metallurgical process.

How To Bleed Hydraulic Cylinder?

Bleeding a hydraulic cylinder is a process that removes air or gas trapped within the cylinder and ensures proper operation and performance. Here’s a step-by-step guide on how to bleed a hydraulic cylinder:

- Preparation:

- Ensure the hydraulic system is powered off and any pressure sources are locked out or depressurized.

- Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards.

- Locate Bleed Valve:

- Identify the bleed valve on the hydraulic cylinder. It is typically located near the top or conveniently for accessing and bleeding air.

- Position Cylinder:

- Position the hydraulic cylinder to allow the air or gas to rise and escape through the bleed valve.

- If necessary, adjust the cylinder’s position, for example, by extending or retracting it partially to facilitate air release.

- Open Bleed Valve:

- Carefully open the bleed valve using an appropriate wrench or tool by turning it counterclockwise.

- Be cautious not to loosen or remove the valve to prevent hydraulic fluid leakage.

- Bleed Air:

- Slowly operate the hydraulic system to pressurize the cylinder, such as activating the pump or actuating the controls.

- As the system operates, air or gas trapped within the cylinder will begin to escape through the open bleed valve.

- Allow the air to bleed entirely until only hydraulic fluid flows from the valve.

- Monitor the hydraulic fluid level in the reservoir and refill if necessary to maintain proper fluid levels.

- Close Bleed Valve:

- Once all the air has been bled, carefully close the bleed valve clockwise until it is snug.

- Ensure the valve is securely closed, but avoid over-tightening to prevent damage.

- Check Cylinder Operation:

- Restore power to the hydraulic system and test the operation of the cylinder.

- Verify that the cylinder extends and retracts smoothly without abnormal noises or vibrations.

- Observe the cylinder’s performance and ensure it operates as expected.

- Regular Maintenance:

- To prevent future air accumulation, implement routine maintenance practices, such as checking for leaks, maintaining proper fluid levels, and addressing any issues promptly.

- Regularly inspect the hydraulic system and cylinders, including seals, connections, and hoses, to identify and resolve potential problems.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best metallurgical hydraulic cylinder manufacturers. We can offer comprehensive metallurgical hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: