HROB Type Standard B Type Circular Hydraulic Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

HROB Type Standard B Type Circular Hydraulic Cylinder

The HROB standard Type B circular hydraulic cylinder is a versatile and reliable hydraulic element that provides efficient power and precise control in various industrial applications. Using advanced technology and high-quality standards, this hydraulic cylinder offers superior performance and durability. Whether in manufacturing, construction, or material handling, HROB standard b cylinders ensure smooth and efficient hydraulic operation.

HRO series round cylinder safe and stable, output, easy maintenance, beautiful appearance, high quality, suitable for all kinds of press.

HROA Type Circular Hydraulic Cylinder Characteristic Data:

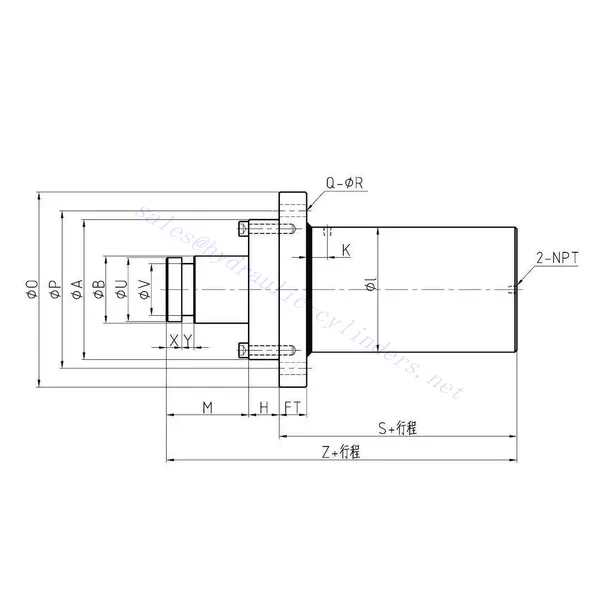

HROA Type Circular Hydraulic Cylinder Structure Diagram:

HROB Type Standard B Type Circular Hydraulic Cylinder Parameter: HROB Type Standard B Type Circular Hydraulic Cylinder External Tooth Type Specification Sheet:

HROB Type Standard B Type Circular Hydraulic Cylinder External Tooth Type Specification Sheet:

HROB Type Standard B Type Circular Hydraulic Cylinder Usage Method:

- Mounting and Installation:

- Determine the appropriate installation location for the HROB type standard B cylinder based on your equipment or mechanical requirements.

- Ensure that the mounting surface is clean, flat, and able to withstand the weight and load of the cylinder.

- Connection to Hydraulic System:

- Connect the hydraulic cylinder to the hydraulic system using a compatible hydraulic hose or pipe.

- Ensure proper alignment and secure connections to prevent leaks and optimize performance.

- Operating the Cylinder:

- The starting hydraulic system applies pressure to initiate the movement of the HROB standard B cylinder.

- The hydraulic control system is used to precisely control the cylinder extension, retraction and positioning to achieve efficient operation.

HROB Type Standard B Type Circular Hydraulic Cylinder Characteristics:

- Robust Construction: HROB Type standard B cylinders are manufactured with high-quality materials to ensure durability and longevity in demanding industrial environments.

- Precision and Control: This hydraulic cylinder provides precise motion and positioning control, allowing for accurate and efficient operation.

- Versatile Applications: HROB standard Type B cylinders are suitable for manufacturing, construction, material handling and other industries.

- Efficient Power Transmission: The cylinders efficiently convert hydraulic energy into mechanical force, providing reliable and consistent power output.

- Smooth Operation: The HROB standard Type B cylinder ensures smooth and reliable operation and minimizes vibration and noise during hydraulic movement.

How Hard Is It To Rebuild A Hydraulic Cylinder?

Rebuilding a hydraulic cylinder can be a complex task that requires mechanical knowledge, experience, and the right tools. The difficulty level involved in the process can vary depending on the specific design and condition of the cylinder. Here are some factors to consider:

- Expertise and Experience:

Rebuilding a hydraulic cylinder requires a good understanding of its components, functionality, and assembly. The process may be more manageable if you have experience working with hydraulic systems or have previously rebuilt hydraulic cylinders. However, if you’re new to hydraulic systems, seeking professional assistance or guidance is recommended. - Cylinder Design:

The complexity of rebuilding a hydraulic cylinder can depend on its design. Some cylinders have more straightforward construction with fewer internal components, making them relatively easier to rebuild. However, more advanced techniques, such as those with multiple stages or integrated features, can be more intricate and challenging to disassemble, reseal, and reassemble correctly. - Condition of the Cylinder:

The overall condition of the hydraulic cylinder also affects the rebuilding process. If the cylinder has severe damage, extensive wear, or corrosion, it may require additional repairs or part replacements, which can add complexity to the rebuild. Assessing the cylinder’s condition beforehand will help determine the level of work needed. - Tools and Equipment:

Rebuilding a hydraulic cylinder often requires specialized tools and equipment. These include hydraulic presses, seal installation tools, snap ring pliers and torque wrenches. Having the necessary tools and knowing how to use them properly is crucial for a successful rebuild. - Seal Replacement and Assembly:

One of the critical steps in rebuilding a hydraulic cylinder is replacing the seals. Ensuring the correct selection and installation of seals is critical for proper functioning and preventing leaks. It requires precision and attention to detail. Additionally, reassembling the cylinder components in the correct order and alignment is crucial for its optimal performance. - Testing and Verification:

After rebuilding the hydraulic cylinder, it’s essential to perform thorough testing to ensure it operates as intended. This can involve pressure testing, checking for leaks, and verifying the cylinder’s range of motion and performance. Proper testing helps identify issues and ensures the cylinder is safe and reliable.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best metallurgical hydraulic cylinder manufacturers. We can offer comprehensive metallurgical hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: