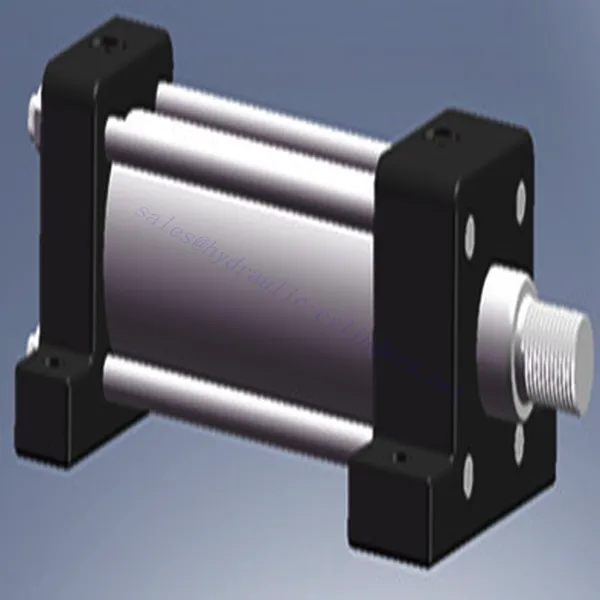

Low-Pressure Hydraulic Cylinder Footstand

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

Low-Pressure Hydraulic Cylinder Footstand

In a low-pressure hydraulic cylinder, the tripod is the component that provides stability and support for the cylinder. It is usually a metal plate or bracket attached to the cylinder’s bottom or base. Tripods have several uses, including:

Stability: The foot base helps to stabilize the hydraulic cylinder and prevent it from tipping or overturning during operation or when subjected to external forces.

Support: The tripod provides a secure base for the cylinder, ensuring that the weight of the cylinder is properly aligned and distributed. It helps maintain the integrity of the cylinder structure and prevents excessive stress on the mounting point.

Mounting: The tripod usually includes holes or slots for mounting or attaching the cylinder to equipment, machinery, or structure. These mounting points allow safe and reliable installation of the cylinder.

Leveling: In some cases, tripods may contain adjustable features such as threaded feet or leveling screws. These allow fine-tuning and leveling of the cylinder to ensure proper operation and alignment with other components.

Low-Pressure Hydraulic Cylinder Footstand Parameter:

Construction Of Low-Pressure Hydraulic Cylinder Footstand:

It is important to note that the design and construction of the tripod can vary depending on the specific cylinder model and application. Some hydraulic cylinders may have integrated tripods as part of their design, while others may require separate tripod attachments for stability and support.

When selecting or installing a bracket for a low-pressure hydraulic cylinder, it is recommended to consult the manufacturer’s documentation or guidelines to ensure compatibility and proper installation procedures. In addition, considering the application’s specific operating conditions and requirements will help determine the appropriate bracket design and functionality required for optimal performance and safety.

How To Find Seal Kit For Hydraulic Cylinder?

To find a seal kit for a hydraulic cylinder, you can follow these steps:

- Gather Information: Collect as much information as possible about the hydraulic cylinder for which you need a seal kit. This includes the make and model of the cylinder, the cylinder’s dimensions (bore size, rod diameter, stroke length), and any other relevant specifications.

- Identify the Manufacturer: Determine the manufacturer of the hydraulic cylinder. This information can usually be found on the cylinder itself or in the equipment documentation. Knowing the manufacturer will help you locate the appropriate seal kit.

- Manufacturer’s Resources: Visit the manufacturer’s website or contact their customer support to inquire about seal kits for their hydraulic cylinders. Many manufacturers offer seal kits specifically designed for their cylinders and can provide guidance on selecting the right kit.

- Distributors and Dealers: Check with authorized distributors or dealers of the hydraulic cylinder manufacturer. These suppliers often carry seal kits for the cylinders they sell. They can provide you with the correct kit based on the cylinder’s make and model.

- Online Suppliers: Search for hydraulic seal kit suppliers or hydraulic component suppliers online. There are numerous websites and online marketplaces that specialize in hydraulic seals and kits. Enter the relevant information about your hydraulic cylinder to find compatible seal kits.

- Dimensions and Specifications: Compare the dimensions and specifications of the seal kits available with the requirements of your hydraulic cylinder. Ensure that the kit matches the cylinder’s bore size, rod diameter, and other critical parameters.

- Quality and Compatibility: Consider the quality and compatibility of the seal kit. It’s important to choose a reputable supplier that provides high-quality seals to ensure proper functioning and longevity of the hydraulic cylinder.

- Purchase and Installation: Once you have identified the appropriate seal kit, proceed with the purchase from the selected supplier. Follow the manufacturer’s instructions for installation or consult a hydraulic system expert if you are unsure about the replacement process.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces; Special cylinder workshop is equipped with various specifications semi-automatic cleaning assembly system, designed annual production capacity of 200,000. Equipped with famous CNC machining equipment, machining center, high-precision cylinder processing special equipment, robot welding machine, automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing key equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality requirements of products.

(2)Machining

The machining shop is equipped with customized inclined rail turning center, machining center, high-speed honing machine, welding robot and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating line, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders, powered by a power chain, with a design capacity of 60 cases per shift.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best low-pressure hydraulic cylinder manufacturers. We can offer wide low-pressure hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: