Low-Pressure Hydraulic Cylinder Intermediate Pin

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

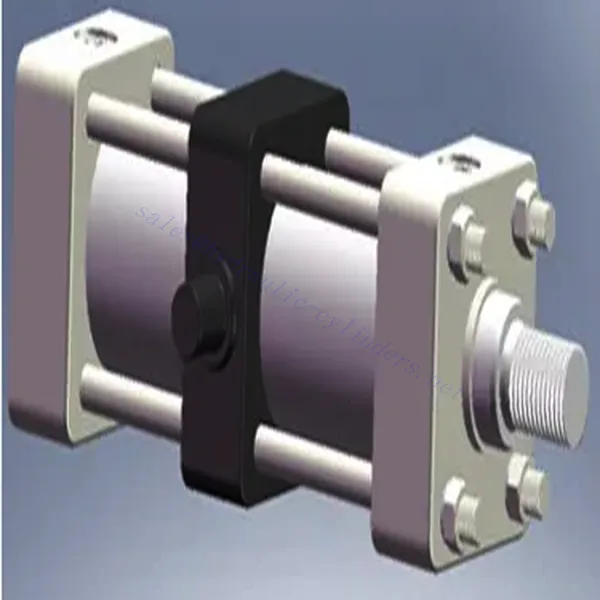

Low-Pressure Hydraulic Cylinder Intermediate Pin

In a low-pressure hydraulic cylinder, the intermediate pin refers to the nail or shaft between the piston and the piston rod. A connecting element transfers force from the piston to the rod, allowing for linear motion.

Design and construction of the low-pressure hydraulic cylinder

Intermediate pins are usually solid metal pins or shafts inside the cylinder.

It connects the two parts between the piston and the connecting rod.

The role of the intermediate pin is to transfer the liquid pressure generated by the piston to the piston rod, thereby achieving the linear movement required by the cylinder.

Low-Pressure Hydraulic Cylinder Intermediate Pin Parameter:

Function and Operation Of Low-Pressure Hydraulic Cylinder Intermediate Pin:

- When hydraulic pressure is applied to the piston, it exerts a force on the middle pin, causing it to move.

- The movement of the intermediate pin transmits force to the piston rod, which causes the hydraulic cylinder to stretch or contract.

- The intermediate pin ensures that the hydraulically generated force is effectively transmitted to the piston rod, thereby achieving the desired movement of the cylinder.

Low-Pressure Hydraulic Cylinder Intermediate Pin Maintenance and Replacement:

- When repairing or modifying the low-pressure hydraulic cylinder, the condition of the middle pin should be checked.

- If there are any signs of wear, damage, or overplay, a new intermediate pin should be replaced to ensure the normal operation of the cylinder.

- When replacing the middle pin, the manufacturer’s guidelines and specifications must be followed to ensure compatibility and optimal performance.

How To Measure A Hydraulic Cylinder?

- Bore Diameter:

- Measure the inside diameter of the cylinder barrel. This is known as the “bore diameter.”

- Place the calipers inside the cylinder barrel and extend the jaws until they contact the inner walls.

- Take note of the measurement displayed on the calipers.

- Rod Diameter:

- Measure the outside diameter of the piston rod. This is known as the “rod diameter.”

- Place the calipers around the piston rod and adjust the jaws until they lightly grip the rod surface.

- Take note of the measurement displayed on the calipers.

- Stroke Length:

- Determine the stroke length, which is the maximum distance the piston can travel inside the cylinder.

- Extend the piston rod to the fully extended position and measure the distance from the front face of the cylinder to the end of the piston rod.

- Take note of the measurement as the stroke length.

- Mounting Dimensions:

- Measure the mounting dimensions to determine how the hydraulic cylinder will be attached to the equipment or structure.

- Measure the distance between the mounting holes or brackets on the cylinder’s mounting flange.

- Measure the hole diameter, if applicable.

- Overall Length:

- Measure the overall length of the hydraulic cylinder, which includes the length of the cylinder barrel, the piston rod, and any other protruding components.

- Place a straightedge across the front face of the cylinder and measure the distance from the front face to the furthest point at the opposite end.

- Additional Measurements:

- Depending on the specific requirements of your application, you may need to measure additional details such as the length of the piston, the thickness of the end caps, or the dimensions of any ports or fittings.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces; Special cylinder workshop is equipped with various specifications semi-automatic cleaning assembly system, designed annual production capacity of 200,000. Equipped with famous CNC machining equipment, machining center, high-precision cylinder processing special equipment, robot welding machine, automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing key equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality requirements of products.

(2)Machining

The machining shop is equipped with customized inclined rail turning center, machining center, high-speed honing machine, welding robot and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating line, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders, powered by a power chain, with a design capacity of 60 cases per shift.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best low-pressure hydraulic cylinder manufacturers. We can offer wide low-pressure hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: