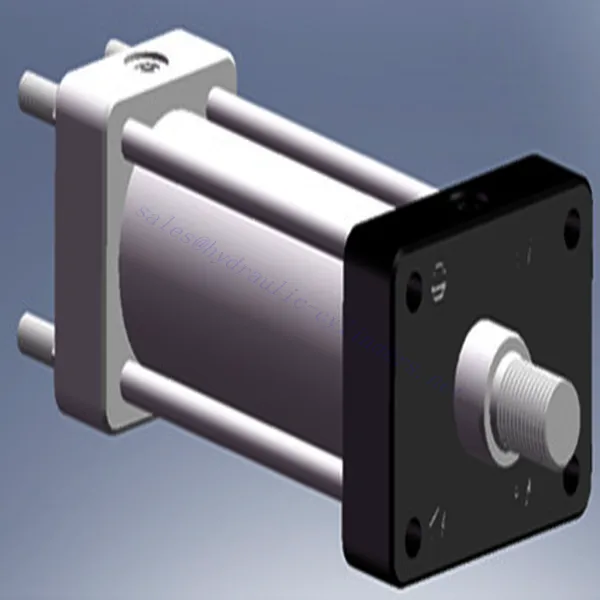

Low-Pressure Hydraulic Cylinder Rear Flange

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

Low-Pressure Hydraulic Cylinder Rear Flange

Rear flange low-pressure hydraulic cylinder refers to a special type of hydraulic cylinder with a flange at the back end. This flange is a mounting point or connection port used to connect the cylinder to other parts or equipment. Below is an overview of low-pressure hydraulic cylinders with rear flanges:

Design and construction of the low-pressure hydraulic cylinder

Cylinder block: The cylinder block is usually high-strength steel or other durable material to withstand hydraulic pressure and external forces. It houses the piston and other internal parts.

Piston and rod: The piston is a cylindrical component moving back and forth in the barrel. It is connected to a rod that extends through the rear end of the cylinder and transmits fluid pressure.

Rear flange: The rear flange is a flat or round plate located at the rear end of the cylinder. It is designed with mounting holes or other connecting mechanisms to allow easy connection to other devices or components.

Low-Pressure Hydraulic Cylinder Rear Flange Parameter:

Applications Of Low-Pressure Hydraulic Cylinder Rear Flange:

- Low-pressure hydraulic cylinders with rear flanges are suitable for a variety of industries and systems operating at lower hydraulic pressures.

- They are commonly used in industrial machinery, mobile devices, and other systems where space limitations or specific installation requirements exist.

- These cylinders are suitable for material handling, lifting mechanisms, conveying systems, and other equipment that requires linear force or movement.

Mounting and Connection Of Low-Pressure Hydraulic Cylinder Rear Flange:

- The rear flange of the low-pressure hydraulic cylinder provides a convenient and secure way to mount and connect the cylinder. It allows for direct attachment to other equipment or structural elements.

- The mounting holes or connection points on the rear flange are typically aligned with corresponding holes or connection points on the equipment or structure it is being attached to.

- Fasteners, such as bolts or screws, are used to secure the rear flange of the cylinder to the mating surface, ensuring a stable and rigid connection.

How To Disassemble Hydraulic Cylinder?

Disassembling a hydraulic cylinder requires careful handling and knowledge of the cylinder’s components. Here is a general guide on how to disassemble a hydraulic cylinder:

- Safety Precautions:

- Ensure that the hydraulic system is depressurized and that there is no residual pressure in the cylinder. Follow proper lock-out/tag-out procedures to prevent accidental activation of the system.

- Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses to protect yourself from hydraulic fluid and potential hazards.

- Cylinder Removal:

- Disconnect the hydraulic lines connected to the cylinder, ensuring that any residual fluid is properly contained.

- If the cylinder is mounted or secured to other components, remove any fasteners or mounting brackets to free the cylinder.

- Carefully lift and remove the cylinder from its mounting position, taking care not to damage or strain any attached hoses or fittings.

- Inspection and Documentation:

- Thoroughly examine the exterior of the cylinder for any signs of damage, leaks, or excessive wear. Document any observations or issues for future reference.

- Take note of the cylinder’s orientation and the position of seals, bearings, and other components before disassembly. This will help during reassembly.

- Disassembling the Cylinder:

- Locate the end caps or retaining rings at each end of the cylinder. These components hold the cylinder barrel and piston assembly together.

- Using appropriate tools, carefully remove the end caps or retaining rings, taking care not to damage any surfaces or components.

- Once the end caps or retaining rings are removed, the cylinder barrel and piston assembly should be free to separate.

- Component Removal:

- Remove the piston from the cylinder barrel, taking note of any seals, bearings, or other components that may be attached to it.

- Inspect and document the condition of all removed components, checking for wear, damage, or signs of leakage. Replace any worn or damaged parts as necessary.

- Clean and Store Components:

- Thoroughly clean all disassembled components using an appropriate cleaning agent to remove any dirt, debris, or hydraulic fluid.

- Store the components in a clean and organized manner, protecting them from contamination and damage.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces; Special cylinder workshop is equipped with various specifications semi-automatic cleaning assembly system, designed annual production capacity of 200,000. Equipped with famous CNC machining equipment, machining center, high-precision cylinder processing special equipment, robot welding machine, automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing key equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality requirements of products.

(2)Machining

The machining shop is equipped with customized inclined rail turning center, machining center, high-speed honing machine, welding robot and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating line, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders, powered by a power chain, with a design capacity of 60 cases per shift.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best low-pressure hydraulic cylinder manufacturers. We can offer wide low-pressure hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: