Rear Rectangular Flange Type Metallurgical Hydraulic Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

Rear Rectangular Flange Type Metallurgical Hydraulic Cylinder

The rear rectangular flange-type metallurgical hydraulic cylinder is a high-performance hydraulic component designed to meet the demanding requirements of metallurgical applications. With its robust construction, precise control, and reliable operation, this metallurgical hydraulic cylinder design stands out in the rigorous environment of steel mills, foundries, and other metallurgical processes. Rear rectangular flange-type cylinders offer superior performance, efficiency, and durability, making them ideal for the metallurgical industry.

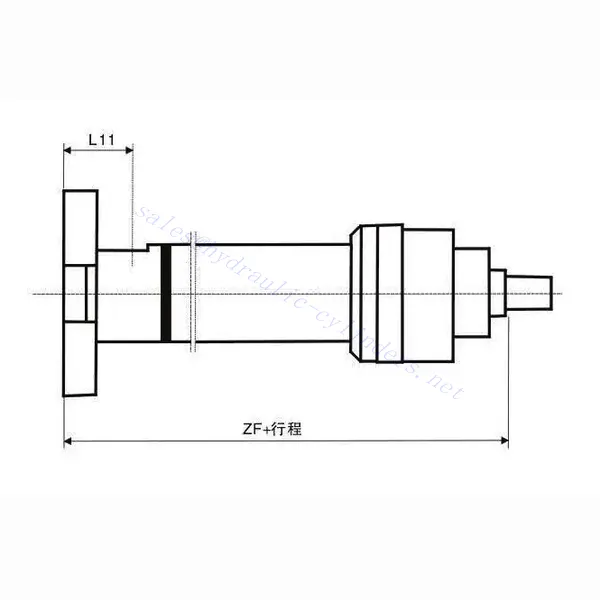

Y-HG1 series of metallurgical equipment hydraulic cylinder for the double acting piston cylinder, cylinder diameter is generally in the range of 40~320mm, the working pressure <=16MPA, the hydraulic oil mechanical system can be used to lose emulsion and other working media, the installation of the flange, earrings, pins, trippers (base) and different types.

High precision CNC honing machine, automatic welding machine, vertical, horizontal machining center, gantry machining center, CNC lathe, and other processing equipment, product quality is stable and guaranteed.

Rear Rectangular Flange Type Metallurgical Hydraulic Cylinder Parameter:

Rear Rectangular Flange Type Metallurgical Hydraulic Cylinder Usage Method:

- Mounting and Installation:

- According to the specific requirements of metallurgical equipment, determine the appropriate installation position of the hydraulic cylinder.

- Ensure the mounting surface is clean, level, and able to support the weight and load of the cylinder.

- Connection to Hydraulic System:

- Connect the metallurgical hydraulic cylinder to the hydraulic system using a compatible hydraulic hose or pipe.

- Ensure proper alignment and secure connections to prevent leaks and ensure optimal performance.

- System Integration and Calibration:

- Integrate hydraulic cylinders into metallurgical equipment or systems by the manufacturer’s guidelines.

- Calibrate the system to achieve desired operating parameters and ensure smooth functioning.

- Operating the Cylinder:

- Start the hydraulic system. Apply pressure to start the movement of the hydraulic cylinder.

- The hydraulic control system precisely controls cylinder extension, contraction, and positioning for efficient metallurgical operations.

Rear Rectangular Flange Type Metallurgical Hydraulic Cylinder Characteristics:

- Rear Rectangular Flange Design: The back rectangular flange design provides secure and reliable connection points, ensuring stability and precise alignment during metallurgical operations.

- Metallurgical Application Focus: This metallurgical hydraulic cylinder is precisely engineered to meet the rigorous demands of metallurgical applications, offering durability and high performance in extreme conditions.

- Precise Control: The cylinder allows precise control and positioning, enabling operators to achieve accurate and efficient metallurgical operations.

- Robust Construction: Constructed from high-quality materials, the metallurgical hydraulic cylinder is designed to withstand heavy loads, extreme temperatures, and harsh operating conditions.

- Efficient Energy Conversion: The cylinder utilizes advanced hydraulic technology to convert hydraulic energy into mechanical force with high efficiency, optimizing productivity in metallurgical processes.

How To Repack A Hydraulic Cylinder?

Repacking a hydraulic cylinder involves replacing the seals and other components to restore proper sealing and prevent leakage. Here is a step-by-step guide on how to repack a hydraulic cylinder:

- Safety Precautions:

- Ensure the hydraulic system is depressurized and the cylinder is isolated from the power source.

- Wear appropriate safety gear, such as gloves and safety glasses, to protect yourself from potential hazards.

- Cylinder Removal:

- Remove the hydraulic cylinder from the equipment or machinery.

- Follow the manufacturer’s guidelines or equipment-specific instructions for proper disconnection.

- Disassembly:

- Carefully disassemble the hydraulic cylinder, noting the order and orientation of the components.

- Keep track of the position and arrangement of seals, pistons, rods, and other internal parts.

- Inspection and Cleaning:

- Thoroughly inspect all cylinder components for wear, damage, or signs of failure.

- Clean all components using an appropriate solvent to remove dirt, debris, and old hydraulic fluid.

- Seal Replacement:

- Identify and replace the worn or damaged seals, including piston seals, rod seals, and wiper seals.

- Ensure that the new seals are compatible with the hydraulic fluid and operating conditions.

- Piston and Rod Maintenance:

- Inspect the piston and piston rod for wear, scoring, or damage.

- If necessary, polish or replace the piston rod to ensure smooth operation.

- Lubricate the piston and rod with a suitable hydraulic fluid or lubricant.

- Cylinder Barrel Inspection:

- Inspect the interior surface of the cylinder barrel for scoring, corrosion, or other damage.

- The cylinder barrel may need to be honed or replaced if significant damage is present.

- Reassembly:

- Reassemble the hydraulic cylinder, ensuring proper alignment and orientation of the components.

- Apply a thin layer of hydraulic fluid or lubricant to the seals and other moving parts for easy assembly and improved sealing.

- Testing and Reinstallation:

- Perform a pressure test to ensure the repacked cylinder functions properly and does not leak.

- Reinstall the hydraulic cylinder into the equipment or machinery, ensuring proper alignment and secure connections.

- Fluid Replacement and System Bleeding:

- Replace the hydraulic fluid with fresh fluid, following the manufacturer’s recommendations.

- Bleed the hydraulic system to remove trapped air, ensuring proper operation and performance.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best metallurgical hydraulic cylinder manufacturers. We can offer comprehensive metallurgical hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: