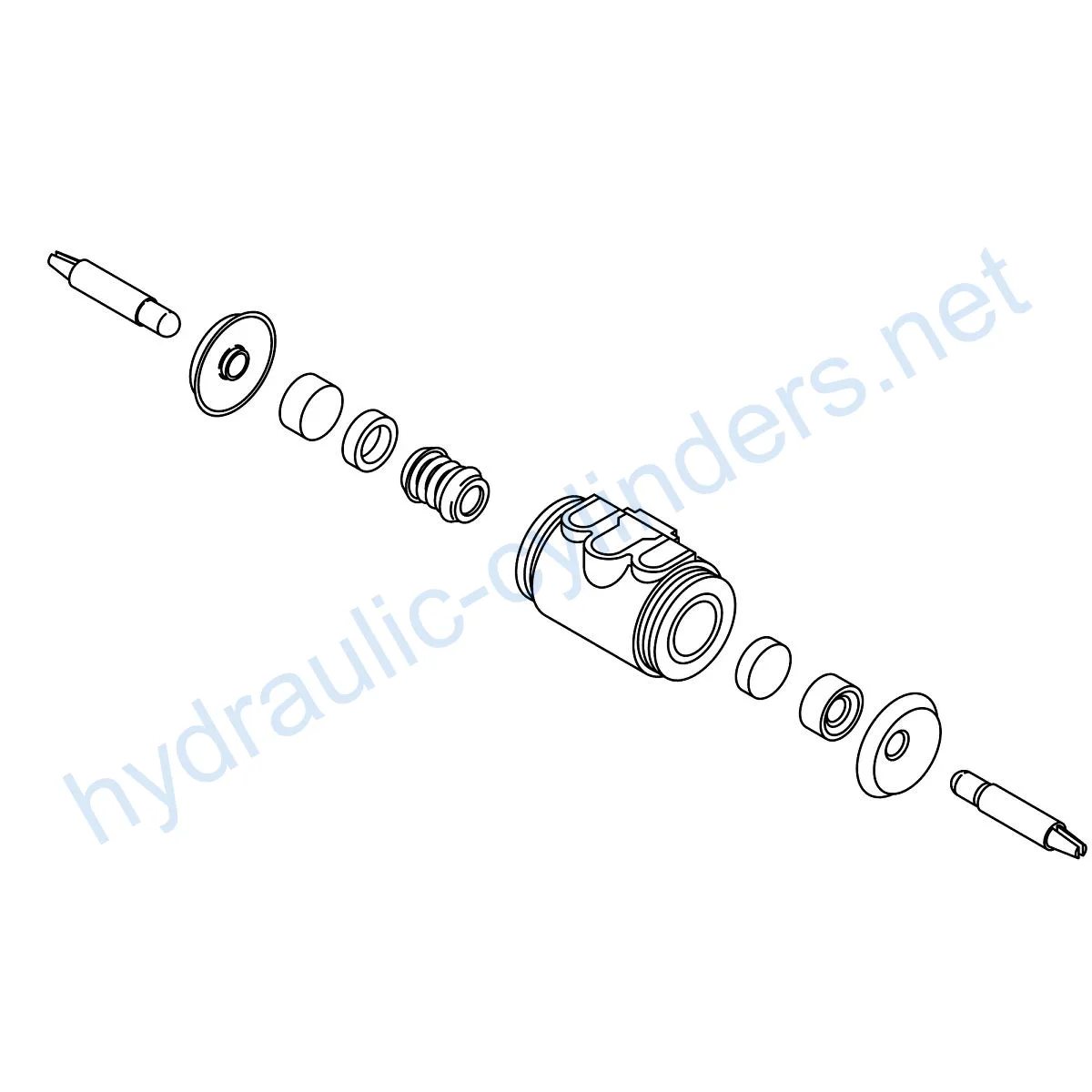

Replacement Of AH131049 Brake Hydraulic Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

Replacement Of AH131049 Brake Hydraulic Cylinder

The Replacement Of AH131049 Brake Hydraulic Cylinder is a crucial component in various equipment models, including 1165, 1170, 1175, 1185, 1450, 1470, and many more. This hydraulic cylinder plays a vital role in the smooth operation and performance of these machines.

Specifications

- Weight: 1.4 lb

- Height: 2.3 in

- Width: 3 in

- Length: 5.75 in

- Volume: 0.172 gal

Compatible Models

- 1165

- 1170

- 1175

- 1185

- 1450

- 1470

- 1550

- 1570

- 2054

- 2056

- 2058

- 2064

- 2066

- 2254

- 2256

- 2258

- 2264

- 2266

- 2266E

- 6610

- 6650

- 6710

- 6750

- 6810

- 6850

- 6910

- 6950

- 7200

- 7250

- 7300

- 7350

- 7400

- 7450

- 7455

- 7500

- 7550

- 7700

- 7750

- 7800

- 7850

- 9400

- 9410

- 9500

- 9510

- 9540

- 9550

- 9560

- 9580

- 9600

- 9610

- 9640

- 9660 WTS

- 9670

- 9680

- 9780

- 9935

- 9970

- 9976

- C670

- CTS

- CTS II

- T550

- T560

- T660

- T670

- W330

- W540

- W550

- W650

- W660

Features

- Improved Equipment Performance: Replacing damaged or worn hydraulic cylinders restores the equipment’s normal operational capabilities, ensuring optimal performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders reduces safety hazards associated with cylinder failures, safeguarding both operators and equipment.

- Overload Protection: Modern cylinder designs often incorporate better overload protection mechanisms, enhancing safety during operation.

- Quick Installation: Contemporary hydraulic cylinders are designed for easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts in the market.

We have the capability to produce this product and provide perfect replacements for these hydraulic cylinders. Our products are designed to meet the same specifications and offer equivalent performance.

Applications

- Excavators: Hydraulic cylinders on excavator arms or buckets may get damaged due to prolonged use or overload, requiring replacement to restore normal operation.

- Cranes: Hydraulic boom cylinders on cranes are prone to wear from frequent lifting and lowering, necessitating periodic replacement to ensure safety.

- Tractors: Front-end loader hydraulic cylinders on tractors may develop leaks or performance degradation from continuous lifting and tilting operations, requiring replacement.

- Harvesters: Hydraulic cylinders in harvesting equipment endure high pressures and can fatigue over time, prompt replacement is essential to maintain productivity.

- Automated Production Lines: Hydraulic cylinders control robotic arms and other automated machinery. Immediate replacement is necessary to avoid reduced production efficiency in case of cylinder failure.

- Die-Casting Machines: Hydraulic cylinders in die-casting machines may experience reduced performance in high-pressure and high-temperature environments. Regular replacements ensure product quality.

- Mining Equipment: Hydraulic cylinders are used for lifting and moving heavy loads in mining equipment. Regular inspection and replacement are necessary to avoid equipment failures in harsh working conditions.

- Bulldozers: Hydraulic cylinder wear on bulldozer push arms can lead to decreased pushing capacity, requiring timely replacement to maintain operational efficiency.

Maintenance Tasks

- Regular Inspections: Periodically inspecting the hydraulic cylinder ensures early detection of potential issues and prevents unexpected failures.

- Proper Lubrication: Adequate lubrication is vital for the smooth operation of hydraulic cylinders. Lubricants prevent friction and wear, extending the cylinder’s lifespan.

- Seal Replacement and Calibration Checks: Replacing worn-out seals and conducting calibration checks help maintain optimal performance and prevent leakage.

During installation, it is essential to provide proper guidance for aligning the cylinder. Using appropriate installation brackets to secure the cylinder is recommended. We also recommend following our suggested inspection

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: