Replacement Of AH228576 Hydraulic Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

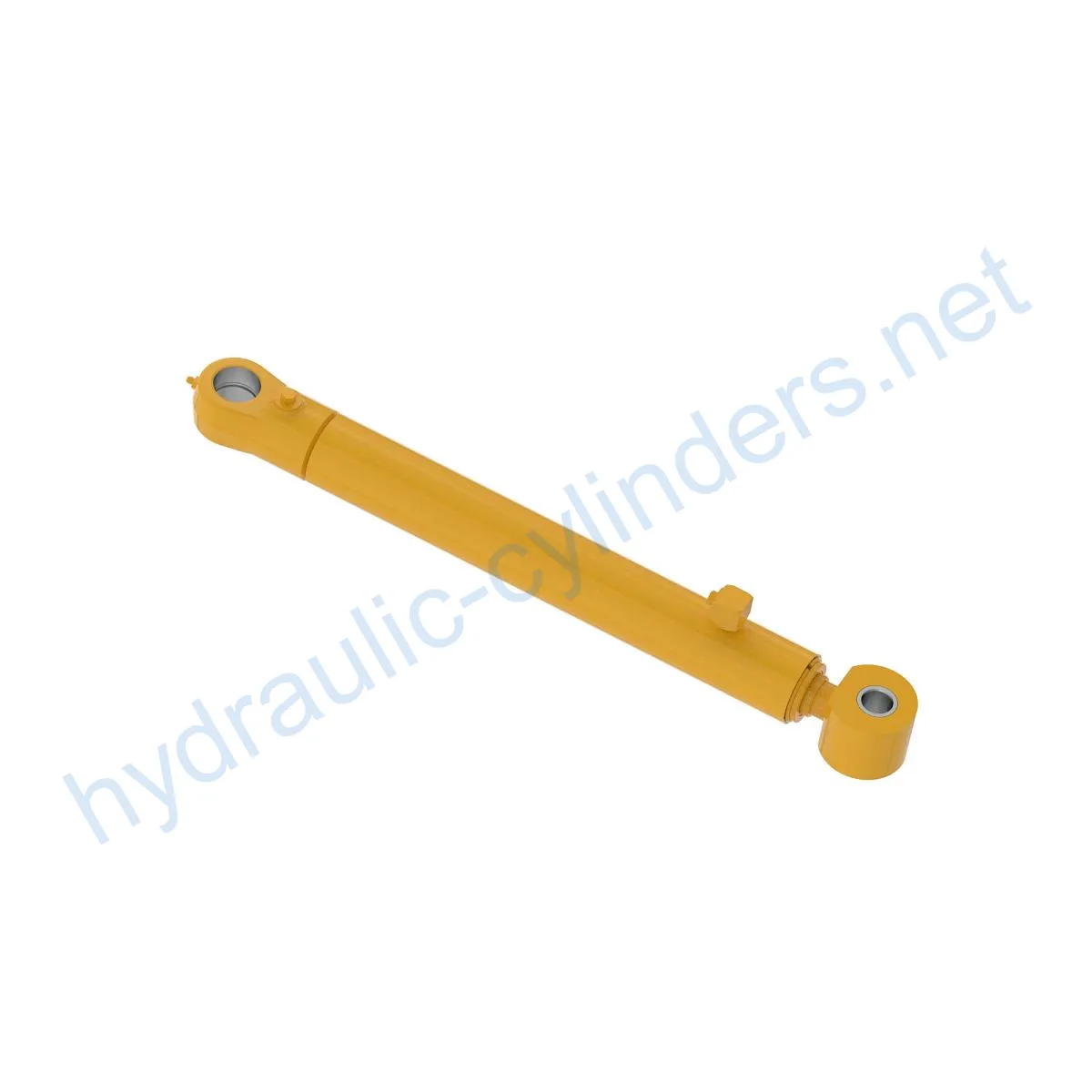

Replacement Of AH228576 Hydraulic Cylinder

First, let’s introduce the product and define what this hydraulic cylinder is and its purpose. The Replacement Of AH228576 Hydraulic Cylinder is a crucial component used in various machinery and equipment. It plays a vital role in controlling the movement and force of hydraulic systems, ensuring smooth and efficient operations.

Specifications and Model

The Replacement Of AH228576 Hydraulic Cylinder has the following specifications:

- Weight: 26.2 lb

- Height: 3 in

- Width: 4 in

- Length: 27.8 in

It is compatible with the following machine models: 313, 315, CT315.

Features

The Replacement Of AH228576 Hydraulic Cylinder offers several key features that make it an excellent choice for replacement. These include:

- Improved Equipment Performance: Replacing damaged or worn-out hydraulic cylinders can restore the normal operational capabilities of equipment, ensuring optimal performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: New cylinder designs often incorporate better overload protection mechanisms, improving overall safety.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts in the market.

We specialize in producing replacement hydraulic cylinders that can perfectly replace these hydraulic cylinders. Our products are designed and manufactured to the highest standards, ensuring excellent performance and reliability.

Applications

The Replacement Of AH228576 Hydraulic Cylinder finds wide application in various industries. Here are three examples:

- Excavators: In excavators, hydraulic cylinders in the boom or bucket may get damaged due to prolonged use or overload, requiring replacement to restore normal operations.

- Cranes: Hydraulic cylinders in crane boom arms are prone to wear and tear during frequent lifting and lowering, necessitating regular replacement to maintain safety.

- Tractors: The front-end loader hydraulic cylinders in tractors may experience leaks or performance degradation due to continuous lifting and tilting operations, requiring replacement.

These are just a few examples of the versatile applications of the Replacement Of AH228576 Hydraulic Cylinder.

Maintenance Tasks

Regular maintenance is essential to ensure the optimal performance and longevity of the Replacement Of AH228576 Hydraulic Cylinder. Here are three common maintenance tasks:

- Periodic Inspection: Regularly inspecting the cylinder for any signs of damage, leakage, or wear is crucial to identify potential issues and take timely action.

- Proper Lubrication: Applying the appropriate amount of hydraulic oil lubrication helps reduce friction and prolong the life of the cylinder components.

- Seal Replacement and Calibration Check: Replacing worn-out seals and periodically checking the cylinder’s calibration ensures proper functioning and prevents potential problems.

During installation, it is important to provide proper alignment guidance and recommend the use of suitable installation brackets to secure the cylinder effectively. We also offer inspection, repair, and replacement services, along with valuable tips to maximize the lifespan of the Replacement Of AH228576 Hydraulic Cylinder.

Safety Considerations and Environmental Factors

When working with hydraulic cylinders, safety measures are of utmost importance. Proper handling, installation, and maintenance practices should be followed to prevent accidents and ensure the safety of personnel and equipment. Additionally, considering environmental factors is crucial to minimize any adverse impact on the surroundings.

Troubleshooting and Common Issues

Here are some common troubleshooting situations and issues related to the Replacement Of AH228576 Hydraulic Cylinder:

- Leakage: If there is a hydraulic fluid leakage from the cylinder, it could indicate a seal failure or damaged components. Inspecting and replacing the affected parts can resolve this issue.

- Lack of Pressure: Insufficient pressure in the hydraulic system may result from a malfunctioning cylinder. Checking the cylinder for any blockages or internal damage is recommended.

- Slow or Erratic Movement: If the cylinder operates slowly or exhibits irregular movement, it may be due to internal wear or contamination. Cleaning or replacing the affected components can help restore proper functionality.

For effective troubleshooting and problem resolution, it is essential to provide tips and solutions to help readers diagnose and address these issues promptly. Additionally, offering preventive measures can help minimize potential problems.

Design Considerations and Selection Criteria

When selecting a hydraulic cylinder, certain design considerations and selection criteria should be taken into account. These include:

- Load-Bearing Capacity: The cylinder should be capable of handling the expected loads to ensure safe and efficient operations.

- Sealing Effectiveness: High-quality seals, such as piston seals and rod seals made of durable materials like polyurethane or nitrile rubber, should be used to minimize leakage.

- Durability: The cylinder body and threaded ends should undergo meticulous surface treatments to enhance wear resistance and prolong service life.

- Safety Features: The cylinder design should incorporate safety features like overload protection mechanisms to prevent catastrophic failures and ensure operator safety.

- Maintainability: Easy access to components and ease of maintenance, such as lubrication and seal replacement, are essential for efficient servicing.

Sealing and Lubrication

The Replacement Of AH228576 Hydraulic Cylinder utilizes various sealing methods to ensure proper performance. These include the use of piston seals, rod seals, and other sealing components. These seals are made from materials like polyurethane and nitrile rubber, known for their excellent wear resistance.

Additionally, the cylinder body and threaded ends undergo meticulous surface treatments to enhance wear resistance and durability. Regular lubrication with the appropriate hydraulic oil is essential to reduce friction, prevent damage, and ensure smooth operation.

Regular Inspection and Preventive Maintenance

Regularly inspecting the Replacement Of AH228576 Hydraulic Cylinder and implementing preventive maintenance measures are vital for optimal performance. This includes proper installation, lubrication, and adjustment. Detailed guidance on aligning the cylinder correctly during installation and recommending appropriate installation brackets for securing the cylinder is crucial. We recommend following recommended inspection, repair, and replacement procedures and providing replacement parts and rebuilding services to enhance the lifespan of the cylinder.

About Our Company

We are a leading manufacturer and wholesale distributor of replacement hydraulic cylinders. With a wide range of products, we have established ourselves as one of the leading manufacturers and distributors in the domestic and international markets.

Our company stands out for the following reasons:

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: