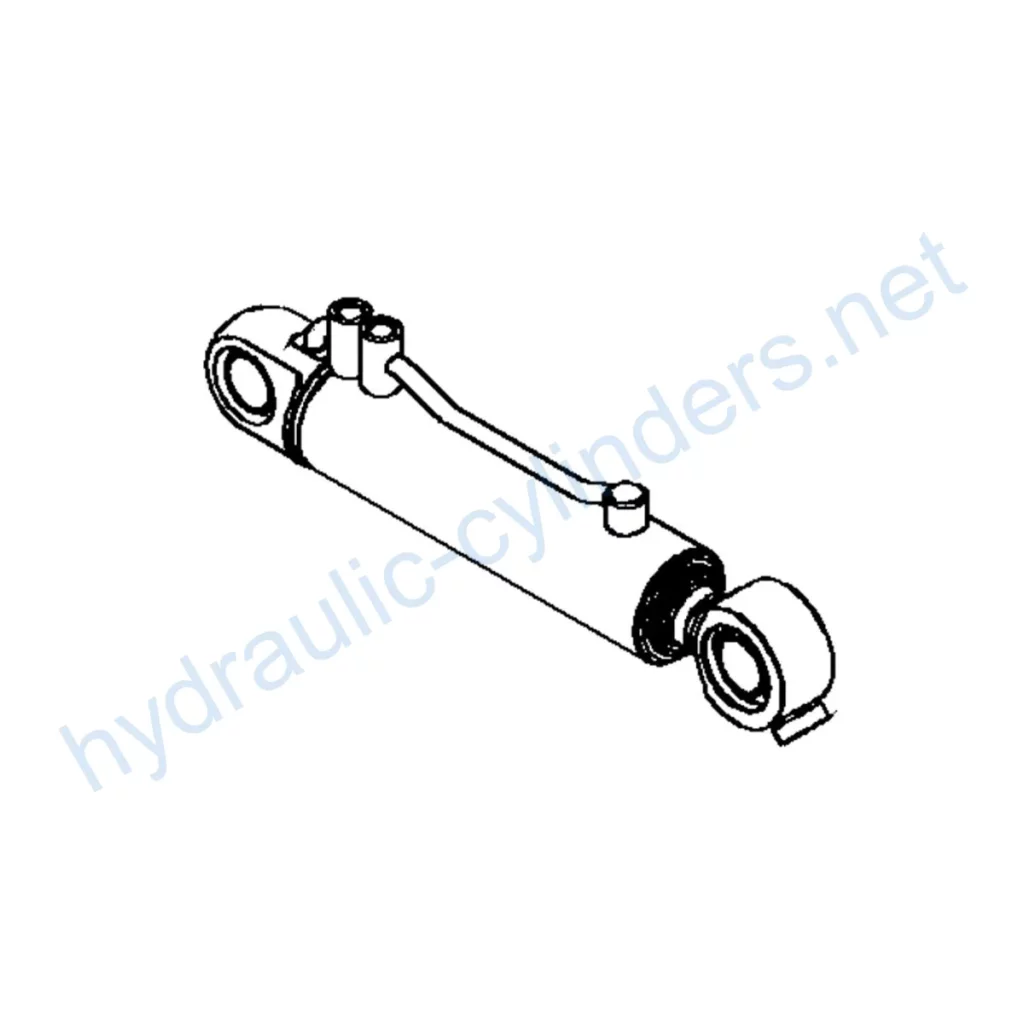

Replacement Of F683339 Hydraulic Cylinder Rod

The Replacement Of F683339 Hydraulic Cylinder Rod is a crucial component in hydraulic systems. This rod is responsible for transferring the force and motion of the hydraulic fluid to various mechanical parts. It plays a vital role in controlling the movement and operation of hydraulic equipment.

Specifications

- Weight: 9.73 lb

- Height: 2.5 in

- Width: 4 in

- Length: 21 in

Model

[Insert Model Information]

Features

- Improved Equipment Performance: Replacing damaged or worn hydraulic cylinders can restore the equipment’s normal operational capabilities, ensuring optimal performance in various applications.

- Enhanced Safety: Regular replacement of hydraulic cylinders reduces safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: New cylinder designs often incorporate better overload protection mechanisms, enhancing overall safety.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts in the market.

Our company specializes in the production of hydraulic cylinders that can perfectly replace these cylinders. We offer high-quality replacements that meet or exceed the specifications of the original cylinders.

Applications

Here are three common examples of the application of hydraulic cylinders:

- Excavators: Hydraulic cylinders in excavator arms or buckets may get damaged from long-term use or overload, requiring replacement to restore normal operation.

- Cranes: Hydraulic cylinders in crane boom arms are prone to wear and tear due to frequent lifting and lowering, necessitating regular replacement to ensure safety.

- Tractors: Hydraulic cylinders in front-end loader attachments of tractors may experience leaks or performance degradation during constant lifting and tilting operations, requiring replacement.

Maintenance Tasks

Regular maintenance is crucial for the longevity and optimal performance of hydraulic cylinders. Here are three common maintenance tasks:

- Regular Inspection: Periodic inspections help identify any signs of wear, leaks, or damage in hydraulic cylinders.

- Proper Lubrication: Adequate lubrication ensures smooth operation and minimizes friction between moving parts.

- Seal Replacement and Calibration Check: Replacing worn seals and checking the calibration of hydraulic cylinders are essential for maintaining their effectiveness.

Safety Considerations and Environmental Factors

When working with hydraulic cylinders, it is vital to prioritize safety measures. Proper handling and adherence to safety protocols are crucial to prevent accidents and ensure the well-being of operators and surrounding environments.

Troubleshooting and Common Issues

Here are some troubleshooting tips and common issues related to hydraulic cylinders:

- [Insert Troubleshooting and Common Issues Description]

Preventive Measures

Prevention is key to avoiding potential issues with hydraulic cylinders. Here are some preventive measures:

- [Insert Preventive Measures Description]

Design Considerations and Selection Criteria

When choosing hydraulic cylinders, several design considerations and selection criteria should be taken into account:

- [Insert Design Considerations and Selection Criteria Description]

Sealing and Lubrication

Proper sealing and lubrication are essential for the optimal performance of hydraulic cylinders. It is recommended to use various sealing components, such as piston seals and rod seals, made of durable materials like polyurethane and nitrile rubber. Additionally, the cylinder body and threaded end surfaces should undergo fine treatment to improve wear resistance. Regular lubrication with the appropriate amount of hydraulic oil is necessary for proper lubrication.

Regular Inspection and Preventive Maintenance

To ensure the longevity and reliability of hydraulic cylinders, regular inspections and preventive maintenance are vital. Proper installation, lubrication, and adjustment play a significant role. During installation, providing accurate alignment guidance and suggesting the use of appropriate mounting brackets to secure the cylinder are important. Recommended inspection, repair, and replacement procedures, as well as offering replacement parts and rebuilding services, can enhance the lifespan of hydraulic cylinders.

Product Installation Guide

[Insert Product Installation Guide Description]

About Our Company

We are a leading manufacturer and wholesale distributor of replacement hydraulic cylinders. Our company offers a comprehensive range of hydraulic cylinders, making us a trusted provider in both domestic and international markets.

Professionalism

We pride ourselves on our professionalism, ensuring the highest quality standards in every aspect of our products and services.

International Certifications

Our products hold international certifications, guaranteeing their reliability and compliance with industry standards.

Customization Services

We offer customization services to meet specific customer requirements, providing tailored solutions for various applications.

State-of-the-Art Production Equipment

Equipped with advanced production equipment, our manufacturing facilities ensure efficient production and consistent product quality.

After-Sales Service

Our dedicated after-sales service team is committed to providing prompt assistance and support to our customers, ensuring their satisfaction and long-term partnership.

Author: lyl