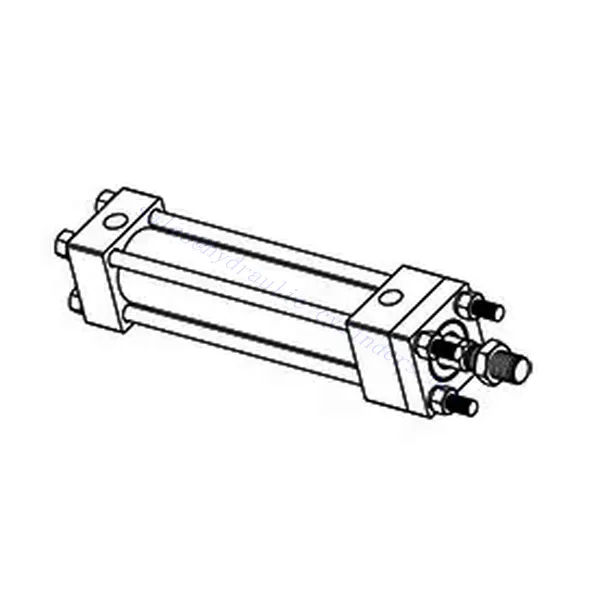

Standard Heavy Rod Hydraulic Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

Standard Heavy Rod Hydraulic Cylinder

The standard heavy rod hydraulic cylinder is a robust and reliable hydraulic element that provides superior power and durability in various industrial applications. Precisely designed to withstand harsh conditions, this hydraulic cylinder is a trusted solution for heavy-duty tasks. From construction equipment to material handling machinery, standard heavy rod hydraulic cylinders are the workhorse to ensure optimal performance and productivity.

Heavy Rod Hydraulic Cylinder Key Characteristics:

1. Robust Construction: Standard heavy rod hydraulic cylinders feature a robust design and high-quality materials such as steel or alloys to withstand heavy loads and harsh operating environments. Its rugged construction ensures long-lasting durability and resistance to wear.

2. Powerful Performance: This heavy rod hydraulic cylinder offers impressive force and power output with its large piston diameter and high-pressure capability. Its ability to lift, push, or pull heavy objects makes it ideal for demanding industrial applications.

3. Versatile Applications: Standard heavy rod hydraulic cylinders suit various industries, including construction, mining, agriculture, and manufacturing. Its versatility enables it to be integrated into multiple devices and systems, providing reliable performance in different applications.

Standard Heavy Rod Hydraulic Cylinder Parameter:

Standard Heavy Rod Hydraulic Cylinder Usage Method:

Mounting and Connection: Install the standard heavy-rod hydraulic cylinder safely into position using appropriate brackets or fixtures. During installation, ensure correct alignment and stability. Follow the manufacturer’s instructions and guidelines to connect hydraulic lines to cylinder ports.

Hydraulic System Integration: The cylinder is integrated into the hydraulic system by connecting it to a suitable hydraulic pump or power unit. Ensure cylinder specifications and operating requirements are met.

Control and Operation: Use the control valve to adjust the hydraulic oil flow into and out of the cylinder. Adjust the control Settings according to the desired linear motion and force output. Test the movement of the cylinder to verify its function and responsiveness.

Standard Heavy Rod Hydraulic Cylinder Maintenance:

Regular maintenance is essential to maximize the lifespan and performance of the Standard Heavy Rod Hydraulic Cylinder. Here are some maintenance guidelines:

Periodic Inspection: Perform routine inspections to identify signs of wear, damage, or leaks. Check for abnormalities in cylinder blocks, piston rods, seals, and other components. Resolve any issues promptly to prevent further injury or operational inefficiencies.

Lubrication: Apply the recommended lubricant to the moving parts of the cylinder, including tie rods and seals. Regular lubrication minimizes friction, reduces wear, and ensures smooth operation. Follow the manufacturer’s guidelines for lubrication intervals and appropriate lubricant types.

Seal Replacement: If seals are found to be deteriorating or leaking, replace seals with genuine parts approved by the manufacturer. Damaged or worn seals can compromise cylinder performance and lead to hydraulic oil leakage.

Cleaning: Clean cylinders by removing dirt, debris, and other contaminants. Before reassembling, use a non-abrasive cleaner and make sure all parts are arid. Regular cleaning promotes optimal performance and prevents premature wear or damage.

How To Check If Hydraulic Cylinder Is Leaking Internally?

To check if a hydraulic cylinder is leaking internally, you can perform the following steps:

- Visual Inspection: Start by visually inspecting the exterior of the hydraulic cylinder. Look for oil or hydraulic fluid around the cylinder body, rod, or seals. External leaks may indicate internal leakage as well.

- Cylinder Operation: Operate the hydraulic cylinder through its full range of motion. Pay attention to any unusual sounds, vibrations, or jerky movements that may indicate internal leakage. If the cylinder operates smoothly without any unusual behavior, it doesn’t necessarily rule out internal leakage, but it suggests that the issue may be less severe.

- External Leakage Test: Wipe the cylinder clean and then visually inspect it for any fresh oil or hydraulic fluid after a period of inactivity. If you notice new oil or fluid on the cylinder’s exterior, it could indicate internal leakage.

- Pressure Drop Test: Perform a pressure drop test to check for internal leakage. Follow these steps:a. Ensure the hydraulic system is depressurized and the cylinder is in a safe position.b. Disconnect the hydraulic lines from the cylinder, carefully capping or plugging the openings to prevent fluid loss.c. Apply pressure to the appropriate port of the cylinder using a hand pump or another hydraulic power source.

d. Monitor the pressure gauge. If the pressure drops significantly over a short period, it suggests internal leakage within the cylinder.

e. Repeat the test on both sides of a double-acting cylinder if applicable.

- Rod Extension Test: Extend the cylinder rod partially or entirely, and then inspect the exposed portion of the rod for any signs of hydraulic fluid. If you notice oil or juice on the rod, it may indicate internal leakage past the rod seals.

- Cylinder Disassembly: If you suspect internal leakage but haven’t identified it through the previous steps, you may need to disassemble the cylinder for a detailed inspection. Disassembling the cylinder allows you to examine the piston, seals, and other internal components for signs of wear, damage, or contamination.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best heavy rod hydraulic cylinder manufacturers. We can offer wide heavy rod hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: