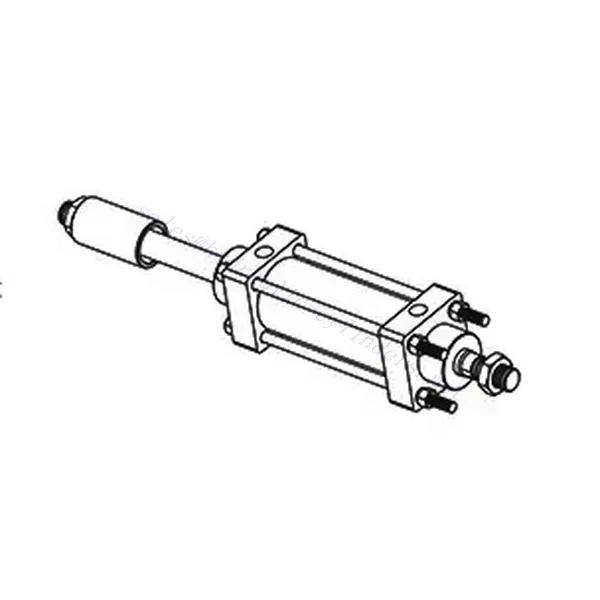

Standard With Adjustable Cap Type Light Rod Hydraulic Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

Standard With Adjustable Cap Type Light Rod Hydraulic Cylinder

The standard with adjustable cap type light rod hydraulic cylinder is a cutting-edge hydraulic cylinder designed to meet the demands of various industrial applications. With its adjustable cap and light pull rod construction, this cylinder offers superior performance, durability, and ease of use. Whether used in manufacturing equipment, construction machinery, or material handling systems, standard adjustable cap light rod hydraulic cylinders provide reliable and efficient operation, making them valuable for optimizing productivity.

Essential Characteristics Of Light Rod Hydraulic Cylinder:

Adjustable Cap Design: The cylinder features an adjustable cap, allowing easy customization and adaptability. The adjustable cap provides the flexibility to fine-tune the stroke length, making it suitable for various applications with different stroke requirements.

Light Pull Rod Construction: Light rod construction is made of lightweight materials such as aluminum or composite piston rods. This structure reduces the overall weight of the cylinder, resulting in faster movement, improved energy efficiency, and lower operating costs.

High Precision and Stability: The standard adjustable cap type light rod hydraulic cylinder is designed to provide high precision and stable linear motion. It ensures accurate positioning, smooth motion, and excellent repeatability, making it ideal for applications requiring precise control and reliability.

Standard With Adjustable Cap Type Light Rod Hydraulic Cylinder Parameter:

Standard With Adjustable Cap Type Light Rod Hydraulic Cylinder Usage Method:

Installation And Connection: Securely install the cylinder into place using the specified mounting brackets or fixtures. Ensure stable installation and correct alignment. Follow the manufacturer’s instructions and guidelines to connect hydraulic lines to cylinder ports.

Cap Adjustment: The adjustable cap function sets the desired stroke length. Use the provided tool or wrench to loosen the cap, adjust the cap to the selected travel, and then tighten it.

Hydraulic System Integration: The cylinder is integrated into the hydraulic system by connecting it to a suitable hydraulic pump or power unit. Ensure cylinder specifications and operating requirements are met.

Control And Operation: Use the control valve to adjust the hydraulic oil flow into and out of the cylinder. Adjust the control Settings to achieve the desired linear motion and force output. Test the movement of the cylinder to verify its function and responsiveness.

Standard With Adjustable Cap Type Light Rod Hydraulic Cylinder Maintenance:

Regular maintenance is essential to ensure optimal performance and extend the lifespan of the Standard With Adjustable Cap Type Light Rod Hydraulic Cylinder’s lifespan. Here are some maintenance guidelines:

- Regular Inspection: Conduct periodic inspections to identify signs of wear, damage, or leaks. Check the cylinder body, rod, seals, and other components for abnormalities. Address any issues promptly to prevent further injury or operational inefficiencies.

- Lubrication: Apply the recommended lubricant to the moving parts of the cylinder, including the rod and seals. Regular lubrication minimizes friction, reduces wear, and ensures smooth operation. Follow the manufacturer’s guidelines for the appropriate lubrication intervals and lubricant type.

- Seal Replacement: If you notice seal deterioration or leakage, replace the seals using genuine manufacturer-approved parts. Incorrect or worn seals can compromise the cylinder’s performance and lead to hydraulic fluid leaks.

- Cleaning: Clean the cylinder by removing dirt, debris, and other contaminants. Use a non-abrasive cleaner and ensure all components are thoroughly dried before reassembly. A clean cylinder promotes optimal performance and prevents premature wear or damage.

How To Replace Hydraulic Cylinder Seals?

Replacing hydraulic cylinder seals is a task that requires precision and attention to detail. Here’s a step-by-step guide on how to replace hydraulic cylinder seals:

- Safety First: Before starting any maintenance work on hydraulic cylinders, ensure that the system is depressurized and the equipment is safely secured to prevent accidental movement.

- Identify the Problem: Determine which seals need to be replaced. Common signs of seal failure include leakage, reduced performance, or visible damage to the seals.

- Gather the Necessary Tools: Prepare the tools you’ll need for the seal replacement, including a seal kit that contains the new seals, retaining rings, O-rings, a seal pick or small screwdriver, a seal installation tool or socket, and a clean cloth or rag.

- Disassembly: Carefully disassemble the hydraulic cylinder. Start by removing any external components, such as mounting brackets or covers. Then, remove the cylinder head or cap to access the seals. Please note the components’ order and orientation as you disassemble them.

- Remove the Old Seals: Gently pry out the old seals from their grooves using a seal pick or small screwdriver. Be cautious not to scratch or damage the cylinder walls or other components.

- Clean and Inspect: Thoroughly clean the cylinder bore and all components to remove dirt, debris, or old seal remnants. Inspect the cylinder bore and other parts for any signs of damage or wear. If any damage is detected, it may be necessary to consult a hydraulic professional for further assessment.

- Install New Seals: Lubricate the new seals with hydraulic oil or a compatible seal lubricant to ease installation. Carefully place the new seals into their grooves, ensuring proper orientation and alignment. Use a seal installation tool or socket to press the seals into place. Be cautious not to damage the seals during installation.

- Reassembly: Once the new seals are in place, reassemble the hydraulic cylinder in the reverse order of disassembly. Pay attention to correctly placing retaining rings, O-rings, and other components. Ensure that all connections are correctly tightened according to the manufacturer’s specifications.

- Test and Check for Leaks: After reassembly, thoroughly inspect the cylinder to ensure proper installation. Slowly pressurize the hydraulic system and check for any signs of leakage. If leaks are detected, troubleshoot and address the issue promptly.

- System Bleeding: If necessary, bleed the hydraulic system to remove any air that may have entered during the seal replacement process. Follow the manufacturer’s recommendations or consult a hydraulic professional for proper bleeding procedures.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best light rod hydraulic cylinder manufacturers. We can offer wide light rod hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: