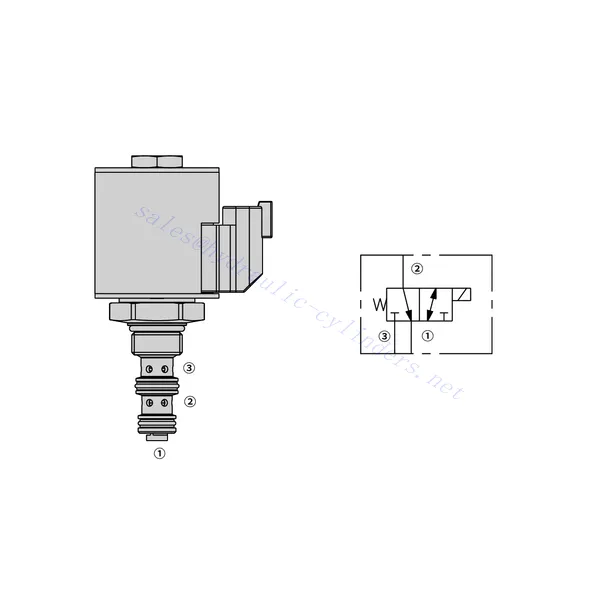

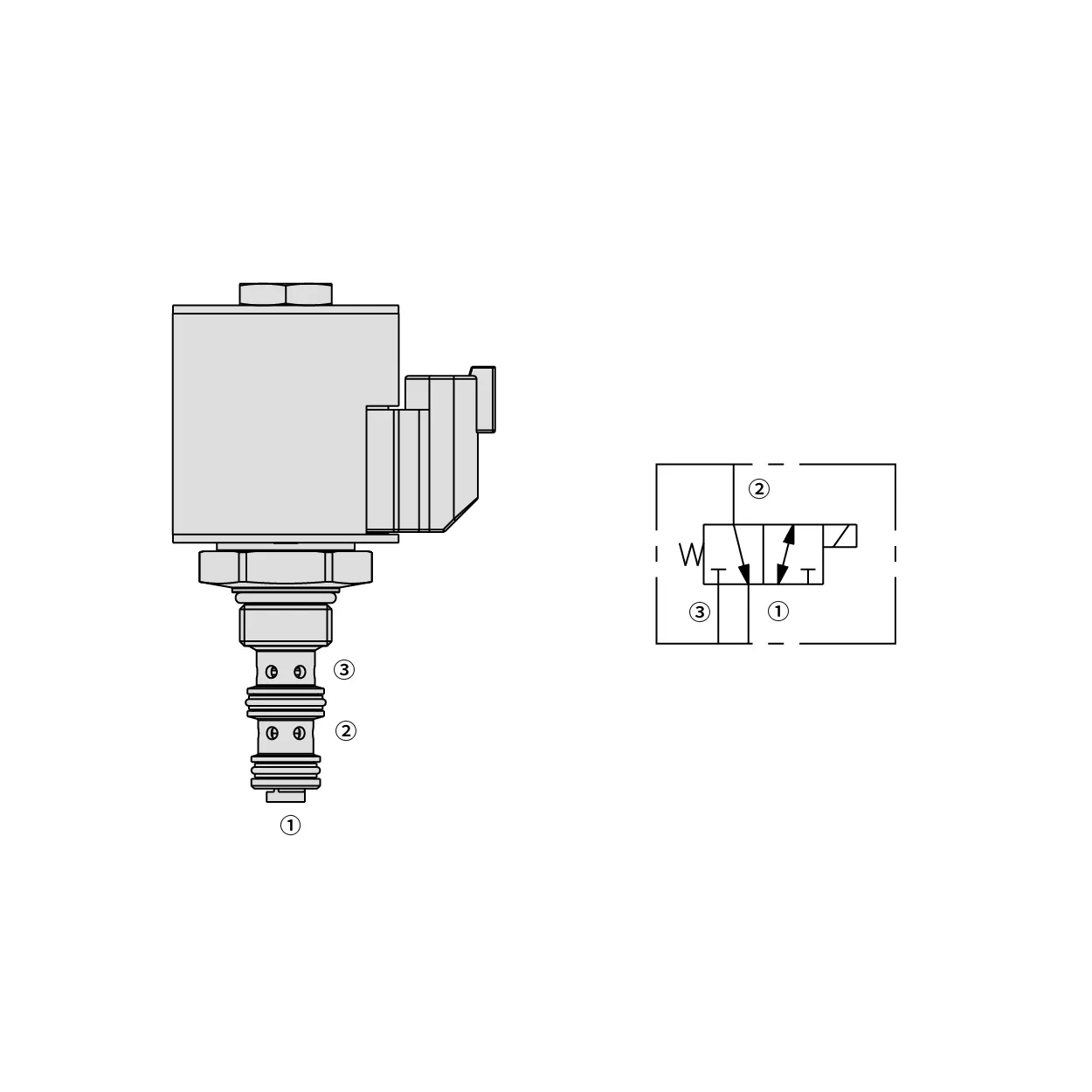

50SD58-30 Solenoid Directional Valve

Como um dos fabricantes, fornecedores e exportadores de produtos mecânicos de cilindros hidráulicos, oferecemos cilindros hidráulicos e muitos outros produtos.

Entre em contato conosco para obter detalhes.

Correio eletrônico:sales@hydraulic-cylinders.net

Fabricante, fornecedor e exportador de cilindros hidráulicos.

50SD58-30 Solenoid Directional Valve

The 50SD58-30 solenoid directional valve is a versatile and high-performance component used in fluid control systems. Designed to provide precise control over fluid flow, this valve offers reliable operation and enhances the efficiency of various industrial applications.

The 30SD16-22 solenoid directional valve is essential for precise fluid control in industrial applications. Its robust construction, efficient performance, and versatility make it an ideal choice for many fluid control systems. Proper maintenance will ensure its optimal functionality and longevity. Invest in the 30SD16-22 solenoid directional valve to enhance fluid control operations and achieve exceptional results.

50SD58-30 Solenoid Directional Valve Characteristics:

- Durable Construction: The 50SD58-30 solenoid directional valve is built with high-quality materials, ensuring durability and resistance to wear, corrosion, and harsh operating conditions. Its robust construction makes it suitable for demanding industrial environments.

- Excellent Flow Control: This valve is engineered to deliver accurate and efficient fluid flow control. It offers exceptional repeatability and response times, enabling precise adjustments to meet specific application requirements.

- Versatile Configuration: The 50SD58-30 solenoid directional valve is available in various configurations, including inline, manifold, or subplate mounting options. This versatility allows for easy integration into different fluid control systems.

- Wide Range of Applications: This valve suits various applications across industries such as manufacturing, automation, process control, and more. It can control hydraulic, pneumatic, or other fluid-based systems.

50SD58-30 Solenoid Directional Valve Parameter:

| Rated pressure | 345 bar(5000 psi) | |

| Peak flow | See performance chart | |

| Fluid | Mineral-based or synthetics with lubricating properties | |

| Fluid temperature range ℃ | -54 to 107 ℃ (Polyurethane seals) | |

| -40 to 100 ℃ (Buna N seals) | ||

| -26 to 204 ℃ (Fluorocarbon seals) | ||

| Viscosity range | 7.4 to 420 mm2/s | |

| Degree of contamination | The minimum pollution level is ISO4406 level 18/16/13, and level 15/13/11 is recommended to prolong the service life | |

| Internal Leakage | Port ③ (De-energized): ≤ 131 mL/min@345 bar | |

| Port ① (Energized): ≤ 279 mL/min@345 bar | ||

| Cavity | VC08-3 | |

| Coil Duty Rating | Continuous from 85% to 115% of nominal voltage | |

| Initial Coil Current Draw at 20℃ | E-coil | 1.7A at 12VDC; 0.85A at 24VDC |

| D-coil | 1.67A at 12VDC; 0.83A at 24VDC | |

| Minimum pull-in voltage | 85% of nominal at 207 bar | |

50SD58-30 Solenoid Directional Valve Advantages:

• Continuous-duty rated coil

• Cartridges are voltage interchangeable

• Optional waterproof E-Coils rated up to IP69K

• Efficient wet-armature construction

• Hardened parts for long life

Usage Method Of 50SD58-30 Solenoid Directional Valve:

- System Assessment: Understand the requirements of your fluid control system, including pressure, flow rate, and directional control needs. Ensure that the 50SD58-30 solenoid directional valve matches the specifications and is suitable for your application.

- Mounting and Connection: Select the appropriate mounting method based on your system layout and available space. Install the valve securely, ensuring proper alignment with the fluid lines. Connect the valve to the system using compatible fittings and connectors, providing tight and leak-free connections.

- Electrical Connection: Connect the valve’s solenoid to the appropriate power supply following the manufacturer’s instructions. Ensure correct wiring and adhere to safety guidelines during the electrical connection process.

- Testing and Adjustment: Gradually introduce fluid flow to the system and monitor the valve’s performance. Test different operating conditions, including pressure and flow variations, and adjust the valve settings to achieve the desired control and system functionality.

How To Replace Delta Shower Valve Cartridge?

Replacing a Delta shower valve cartridge is a common task that can help resolve issues such as leaks, temperature control problems, or water flow inconsistencies. Here’s a step-by-step guide on how to replace a Delta shower valve cartridge:

- Gather the necessary tools: Before you begin, make sure you have the following tools ready: adjustable wrench, Phillips screwdriver, needle-nose pliers, Allen wrench set, and a replacement cartridge specific to your Delta shower valve model.

- Turn off the water supply: Locate the main water shut-off valve for your home and turn it off to stop the water flow to the shower. If there is no dedicated shut-off valve for the shower, you may need to shut off the main water supply.

- Remove the handle: Depending on the Delta shower valve model, the handle removal method may vary. For single-handle valves, locate the set screw on the handle, usually located under a decorative cap or button. Use a Phillips screwdriver to remove the set screw, then pull the handle straight off. For two-handle valves, look for a small set screw on the base of each handle. Remove the set screws and then lift the handles off.

- Remove the trim sleeve and escutcheon plate: Next, remove the trim sleeve and escutcheon plate, which are usually located around the valve body. These components may be threaded or held in place with screws. Unscrew or remove any screws and gently pull or twist the sleeve and escutcheon plate to detach them from the wall.

- Disconnect the cartridge: Once you gain access to the cartridge, you may need to remove a retaining clip or nut that secures it in place. Use needle-nose pliers or an adjustable wrench to carefully loosen and remove the clip or nut. With the clip or nut removed, you can now pull the cartridge straight out of the valve body. If it’s stuck, you can use a cartridge puller tool for added leverage.

- Install the new cartridge: Take the replacement Delta shower valve cartridge and align it with the valve body, ensuring that any tabs or notches match up correctly. Gently push the cartridge into the valve body until it fits snugly.

- Reassemble the valve: Once the new cartridge is installed, reassemble the valve by following the steps in reverse order. Secure the cartridge with the retaining clip or nut, then reattach the trim sleeve and escutcheon plate. Make sure all components are tightened securely but avoid over-tightening.

- Test for leaks and functionality: Turn the water supply back on and test the shower. Check for any leaks around the valve and ensure that the hot and cold water controls are working correctly. If necessary, make any adjustments to the cartridge or connections to resolve any issues.

- Reinstall the handle: Finally, reattach the handle by aligning it with the cartridge stem and securing it with the set screw. Make sure the handle sits flush and operates smoothly.

Aptidão e capacidade da fábrica:

(1) Montagem

Temos uma plataforma de montagem de pesquisa e desenvolvimento independente de primeira classe. A oficina de produção de cilindros hidráulicos tem quatro linhas de montagem semiautomáticas de cilindros de elevação e uma linha de montagem automática de cilindros de inclinação, com uma capacidade de produção anual projetada de 1 milhão de peças. A oficina de cilindros especiais é equipada com várias especificações de um sistema de montagem de limpeza semiautomática com uma capacidade de produção anual projetada de 200.000 peças e equipada com famosos equipamentos de usinagem CNC, um centro de usinagem, um equipamento especial de processamento de cilindros de alta precisão, uma máquina de solda robotizada, uma máquina de limpeza automática, uma máquina de montagem automática de cilindros e uma linha de produção de pintura automática. O equipamento crítico existente é de mais de 300 conjuntos (conjuntos). A alocação ideal e o uso eficiente dos recursos do equipamento garantem os requisitos de precisão dos produtos e atendem às necessidades de alta qualidade dos produtos.

(2) Usinagem

A oficina de usinagem é equipada com um centro de torneamento de trilho inclinado personalizado, um centro de usinagem, uma máquina de brunimento de alta velocidade, um robô de soldagem e outros equipamentos relacionados, que podem lidar com o processamento de tubos de cilindros com diâmetro interno máximo de 400 mm e comprimento máximo de 6 metros.

(3) Soldagem

(4) Pintura e revestimento

Com linhas de revestimento de tinta à base de água automáticas de cilindros de pequeno e médio porte, para obter carregamento e descarregamento automáticos de robôs e pulverização automática, a capacidade projetada é de 4.000 peças por turno;

Também temos uma linha de produção de tinta semiautomática para cilindros grandes, acionada por uma corrente elétrica, com capacidade de projeto de 60 caixas por turno.

(5) Testes

Temos instalações de inspeção e bancos de teste de primeira classe para garantir que o desempenho do cilindro atenda aos requisitos.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding caixas de câmbio agrícolas. Exportamos nossos produtos para clientes em todo o mundo e conquistamos uma boa reputação devido à qualidade superior de nossos produtos e ao serviço pós-venda. Convidamos clientes nacionais e estrangeiros a entrar em contato conosco para negociar negócios, trocar informações e cooperar conosco!

Faça um tour pela nossa fábrica de RV:

Faça um tour pela nossa fábrica de RV com o seguinte

Cilindro hidráulico Aplicação: