HM7X Series Axial Piston Fixed Displacement Hydraulic Motor

Como um dos fabricantes, fornecedores e exportadores de produtos mecânicos de cilindros hidráulicos, oferecemos cilindros hidráulicos e muitos outros produtos.

Entre em contato conosco para obter detalhes.

Correio eletrônico:sales@hydraulic-cylinders.net

Fabricante, fornecedor e exportador de cilindros hidráulicos.

HM7X Series Axial Piston Fixed Displacement Hydraulic Motor

The HM7X series axial piston fixed displacement hydraulic motor is a cutting-edge product designed to deliver exceptional power and efficiency in hydraulic systems. With its advanced features, durable construction, and precise control, this hydraulic motor sets new standards in the industry.

The HM7X series axial piston fixed displacement hydraulic motor is a powerful and efficient solution for hydraulic systems. Its robust design, high power density, and precise control offer exceptional performance, reliability, and longevity. By following the recommended usage methods and adhering to regular maintenance practices, the hm7x series motor will continue to deliver outstanding power and efficiency. Embrace the power and efficiency of the HM7X series axial piston fixed displacement hydraulic motor to unlock the full potential of your hydraulic system.

HM7X Series Axial Piston Fixed Displacement Hydraulic Motor Key Characteristics:

- Robust and Reliable Design: The HM7X series motor boasts a complete axial piston design, ensuring durability and reliability even in the most demanding applications. Crafted with high-quality materials and precision engineering, it can withstand high pressures and adverse operating conditions.

- High Power Density: Despite its compact size, the HM7X series motor offers an impressive power density, allowing it to deliver exceptional power output while occupying minimal space. This feature provides system design and installation flexibility, especially in applications with limited room.

- Efficient Power Transmission: The axial piston design of the HM7X series motor ensures efficient power transmission, minimizing energy losses and maximizing overall system efficiency. This results in reduced fuel consumption, lower operating costs, and a smaller carbon footprint, making it an environmentally friendly choice.

- Precise Control and Performance: The HM7X series motor offers precise control over speed and torque, allowing operators to tailor the motor’s output to match the application’s specific requirements. This accurate control leads to superior performance, smooth operation, and enhanced productivity.

HM7X Series Axial Piston Fixed Displacement Hydraulic Motor Parameter:

| Size | 45 | 63 | 75 | 85 | 100 | 130 |

| Max. Displacement cc/rev | 45 | 63 | 75 | 85 | 100 | 130 |

| Max. speed min-1 | 4000 | 5000 | 4500 | 4500 | 3550 | 3400 |

| Rated pressure bar | 280 | 400 | 400 | 400 | 400 | 400 |

| Max. pressure bar | 350 | 450 | 450 | 450 | 450 | 450 |

| Theoretical output torque Nm | 280 | 401 | 478 | 542 | 636 | 830 |

| Power Kw | / | 210 | 225 | 255 | 236 | 269 |

| Max. Flow L/min | 180 | 315 | 337 | 382 | 355 | 442 |

| Moment of inertia kg.m2 | 0.0036 | 0.0072 | 0.0072 | 0.011 | 0.015 | 0.025 |

| Volume in the case L | 0.7 | 1 | 1 | 0.5 | 0.5 | 1.2 |

| Mass Kg | 19.4 | 26 | 30.5 | 26 | 38 | 64.8 |

| Oil viscosity mm2/s | 5 ~ 1600,Best range:16~36 | / | ||||

| Temperature ℃ | at drain port: -20 ~ +115 at inlet port:-20 ~ +90 |

|||||

HM7X Series Axial Piston Fixed Displacement Hydraulic Motor Advantages:

HM7X45

• Swash plate type quantitative axial piston motor for open or closed type hydraulic drive circuit.

• Excellent high-speed performance.

• Plug-in design, compact installation space.

• High power to weight ratio.

• The bearing longevity is realized by the swash plate structure.

• The motor oil port is concentrated on one side for easy installation and oil circuit layout.

• Anti-reverse valve can be integrated

HM7X63/75/85/100/130/160

• High speed operation and smooth starting characteristics: Optimized rotary balance design high-speed performance and excellent starting characteristics.

• Low speed operation:Superior performance in low speed operation provides excellent controllability.

• Compact size:Swash plate conguration enables the motor to be much more compact.

• Long bearing life:Swash plate conguration results in longer bearing life.

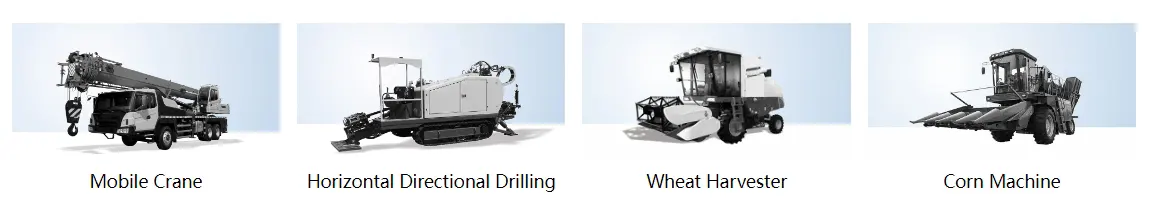

HM7X Series Axial Piston Fixed Displacement Hydraulic Motor Application:

Usage Method Of HM7X Series Axial Piston Fixed Displacement Hydraulic Motor:

- Mounting and Integration: Select a suitable location within your hydraulic system to mount the HM7X series axial piston fixed displacement hydraulic motor. Ensure proper alignment and securely mount the motor using appropriate brackets or accessories. Connect the motor to the hydraulic system using compatible fittings and hoses, ensuring tight and leak-free connections.

- Fluid Compatibility: Verify that the hydraulic fluid used in your system is compatible with the HM7X series motor. Refer to the manufacturer’s recommended fluid type, viscosity, and temperature range. Regularly monitor and maintain the hydraulic fluid to ensure optimal motor operation and longevity.

- Speed and Torque Control: Familiarize yourself with the speed and torque control options provided with the HM7X series motor. Depending on the specific model, it may offer various control methods, such as manual or proportional control. Understand the recommended control settings and adjust them accordingly to optimize motor performance.

- Load Considerations: Consider your application’s load requirements using the HM7X series motor. Ensure the motor’s power and torque ratings suit the intended task. Avoid overloading the engine to prevent excessive wear and potential damage.

How To Remove Hydraulic Clutch Line From Master Cylinder?

To remove the hydraulic clutch line from the master cylinder, follow these steps:

- Precauções de segurança: Ensure the hydraulic system is depressurized before starting the disconnection process. This involves removing pressure from the system by releasing the clutch pedal several times or using a pressure-relief tool if available. Also, wear safety goggles and gloves to protect yourself from any potential fluid leakage.

- Locate the Master Cylinder: Identify the master cylinder, which is typically located on the engine compartment’s firewall. It is connected to the clutch pedal by a push rod and is easily identifiable by its fluid reservoir and hydraulic line connections.

- Access the Hydraulic Line: Depending on the vehicle’s make and model, you may need to remove other components or panels to gain access to the hydraulic line connected to the master cylinder. Use tools like wrenches or sockets to remove any necessary parts obstructing access.

- Position a Drain Pan: Place a drain pan or a suitable container beneath the hydraulic line connection point to catch any fluid that may drain out during the disconnection process.

- Loosen the Fittings: Locate the fittings that connect the hydraulic line to the master cylinder. These fittings are usually secured with retaining nuts or banjo bolts. Use an appropriate wrench or socket to loosen the fittings counterclockwise. Be cautious not to damage the fittings or the surrounding components.

- Remove the Line: Once the fittings are sufficiently loosened, carefully pull the hydraulic line away from the master cylinder. If the line feels stuck, gently wiggle it while applying a slight pulling force to release it from any residual pressure or corrosion.

- Cap the Openings: After removing the hydraulic line, quickly cap the master cylinder and the open end of the line with suitable caps or plugs to prevent dirt, debris, or fluid leakage. This step is crucial to maintain the cleanliness and integrity of the system during the line’s disconnection.

- Inspect and Replace: Take this opportunity to inspect the hydraulic line for any signs of damage, wear, or leaks. If necessary, replace the line with a new one to ensure proper functionality and prevent future issues.

Aptidão e capacidade da fábrica:

(1) Montagem

Temos uma plataforma de montagem de pesquisa e desenvolvimento independente de primeira classe. A oficina de produção de cilindros hidráulicos tem quatro linhas de montagem semiautomáticas de cilindros de elevação e uma linha de montagem automática de cilindros de inclinação, com uma capacidade de produção anual projetada de 1 milhão de peças. A oficina de cilindros especiais é equipada com várias especificações de um sistema de montagem de limpeza semiautomática com uma capacidade de produção anual projetada de 200.000 peças e equipada com famosos equipamentos de usinagem CNC, um centro de usinagem, um equipamento especial de processamento de cilindros de alta precisão, uma máquina de solda robotizada, uma máquina de limpeza automática, uma máquina de montagem automática de cilindros e uma linha de produção de pintura automática. O equipamento crítico existente é de mais de 300 conjuntos (conjuntos). A alocação ideal e o uso eficiente dos recursos do equipamento garantem os requisitos de precisão dos produtos e atendem às necessidades de alta qualidade dos produtos.

(2) Usinagem

A oficina de usinagem é equipada com um centro de torneamento de trilho inclinado personalizado, um centro de usinagem, uma máquina de brunimento de alta velocidade, um robô de soldagem e outros equipamentos relacionados, que podem lidar com o processamento de tubos de cilindros com diâmetro interno máximo de 400 mm e comprimento máximo de 6 metros.

(3) Soldagem

(4) Pintura e revestimento

Com linhas de revestimento de tinta à base de água automáticas de cilindros de pequeno e médio porte, para obter carregamento e descarregamento automáticos de robôs e pulverização automática, a capacidade projetada é de 4.000 peças por turno;

Também temos uma linha de produção de tinta semiautomática para cilindros grandes, acionada por uma corrente elétrica, com capacidade de projeto de 60 caixas por turno.

(5) Testes

Temos instalações de inspeção e bancos de teste de primeira classe para garantir que o desempenho do cilindro atenda aos requisitos.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding caixas de câmbio agrícolas. Exportamos nossos produtos para clientes em todo o mundo e conquistamos uma boa reputação devido à qualidade superior de nossos produtos e ao serviço pós-venda. Convidamos clientes nacionais e estrangeiros a entrar em contato conosco para negociar negócios, trocar informações e cooperar conosco!

Faça um tour pela nossa fábrica de RV:

Faça um tour pela nossa fábrica de RV com o seguinte

Cilindro hidráulico Aplicação: