Mobile Crane Counterweight Cylinder

Como um dos fabricantes, fornecedores e exportadores de produtos mecânicos de cilindros hidráulicos, oferecemos cilindros hidráulicos e muitos outros produtos.

Entre em contato conosco para obter detalhes.

Correio eletrônico:sales@hydraulic-cylinders.net

Fabricante, fornecedor e exportador de cilindros hidráulicos.

Mobile Crane Counterweight Cylinder

The mobile crane counterweight cylinder is a vital component that plays a crucial role in achieving balance and stability during lifting operations. Designed specifically for mobile cranes, this hydraulic cylinder ensures the controlled movement and positioning of the counterweight, optimizing the crane’s lifting capacity and enhancing overall safety.

The mobile crane counterweight cylinder is an indispensable component that enables balance, stability, and enhanced safety in mobile crane lifting operations. With its robust construction, precise hydraulic control, and ability to adjust the counterweight position, this hydraulic cylinder optimizes the crane’s lifting capacity and ensures controlled movement, minimizing the risk of accidents and ensuring safe and efficient lifting. Following proper usage methods and adhering to recommended maintenance practices, operators can maximize the lifespan and reliability of the mobile crane counterweight cylinder, leading to successful and secure lifting operations. Choose this essential hydraulic component for balance, stability, and safety in your mobile crane lifting endeavors.

Mobile Crane Counterweight Cylinder Key Characteristics:

- Robust Construction and Durability:

- The mobile crane counterweight cylinder boasts a robust construction, utilizing high-quality materials to ensure strength and durability.

- It is engineered to withstand heavy loads, shocks, and harsh environmental conditions, guaranteeing reliable performance even in demanding work environments.

- Hydraulic Control and Precision:

- This cylinder operates through a hydraulic control system, allowing for precise movement and adjustment of the counterweight.

- The hydraulic control ensures smooth and controlled operation, enabling operators to achieve the desired balance with utmost precision.

- Optimal Counterweight Positioning:

- The mobile crane counterweight cylinder facilitates the controlled movement and positioning of the counterweight.

- Adjusting the counterweight’s position allows operators to achieve improved stability and enhance the crane’s lifting capacity, enabling safe and efficient lifting operations.

- Enhanced Safety and Stability:

- The counterweight plays a significant role in counterbalancing the lifted load maintaining the crane’s stability throughout the operation.

- The mobile crane counterweight cylinder enables precise control over the counterweight, ensuring balanced and stable lifting, reducing the risk of accidents, and enhancing overall safety.

Mobile Crane Counterweight Cylinder Parameter:

| Product Name | Mobile Crane Counterweight Cylinder |

| Features: | For the installation of counterweights, |

| Bore diameter: | 85mm~320mm |

| Rod diameter: | 55mm~180mm Stroke≤1500mm |

| Pressure: | Maximum 35MPa |

| Telescopic Cylinder Applications: | Mobile Crane |

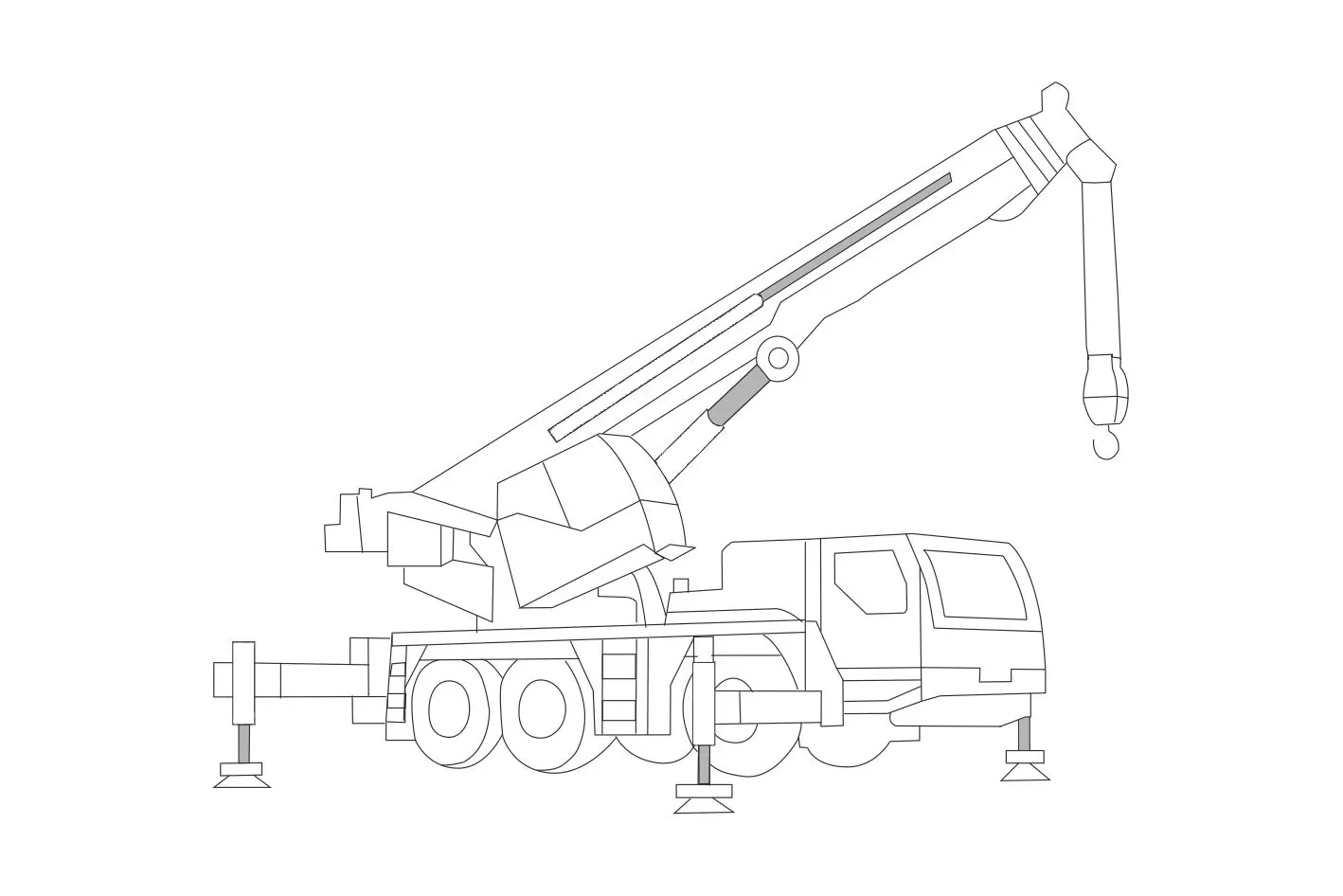

Mobile Crane Identification Diagram:

Usage Method Of Mobile Crane Counterweight Cylinder:

- Familiarize with Controls and Safety Guidelines:

- Before operating the mobile crane counterweight cylinder, operators must familiarize themselves with the crane’s controls and safety guidelines.

- Ensure that all safety procedures and precautions, including proper counterweight positioning, are followed to ensure safe lifting operations.

- Adjusting the Counterweight:

- The hydraulic controls adjust the counterweight’s position per the lifting requirements.

- Gradually move the counterweight to achieve the desired balance and stability.

- Monitor the crane’s performance and adjust the counterweight position during the lifting operation as needed.

- Fine-Tuning the Balance:

- Throughout the lifting operation, operators should continuously monitor the crane’s stability.

- If required, make minor adjustments to the counterweight position to maintain the crane’s balance and ensure safe lifting.

What Are The Main Components Of A Hydraulic System?

A hydraulic system consists of several key components that work together to transmit power and control the movement of fluids. The main components of a hydraulic system are:

- Hydraulic Fluid:

- Hydraulic fluid is the medium through which power is transmitted in a hydraulic system.

- It is typically a specially formulated oil with excellent lubricating and pressure transmission properties.

- The hydraulic fluid transfers force from one component to another and plays a vital role in the overall system performance.

- Hydraulic Pump:

- The hydraulic pump generates flow and provides the necessary pressure to move the hydraulic fluid.

- It converts mechanical energy into hydraulic energy, typically from an electric motor or an engine.

- The pump draws in hydraulic fluid from the reservoir and delivers it to the rest of the hydraulic system at high pressure.

- Reservoir:

- The reservoir, also known as the hydraulic tank, stores the hydraulic fluid.

- It provides a fluid supply for the pump and helps dissipate heat generated during system operation.

- The reservoir usually contains a filter to remove contaminants and a halt to maintain the proper fluid level and prevent the entry of contaminants or air.

- Hydraulic Actuators:

- Hydraulic actuators are devices that convert hydraulic energy into mechanical force or motion.

- The two most common hydraulic actuators are hydraulic cylinders and hydraulic motors.

- Hydraulic cylinders utilize the pressure of the hydraulic fluid to generate linear motion, while hydraulic motors convert fluid pressure into rotary motion.

- Control Valves:

- Control valves regulate the flow and pressure of hydraulic fluid throughout the system.

- They direct the fluid to different actuators and control the speed and direction of movement.

- Control valves can be manually operated or automated using solenoids or other control mechanisms.

- Hydraulic Lines and Hoses:

- Hydraulic lines and hoses transport the hydraulic fluid between various components of the system.

- They are designed to withstand high-pressure conditions and are constructed from materials that are compatible with hydraulic fluids.

- Proper installation and maintenance of hydraulic lines and hoses are crucial to prevent leaks and ensure optimal system performance.

- Accumulators:

- Accumulators store pressurized hydraulic fluid for future use.

- They help maintain system pressure, absorb shocks, and provide additional power during peak demand.

- Accumulators are often used in applications where rapid or intermittent hydraulic energy is required.

- Filters:

- Filters remove contaminants and impurities from the hydraulic fluid.

- They prevent particles, debris, and other contaminants from causing damage to system components and ensure fluid cleanliness.

- Filters are typically installed in the hydraulic lines or within the reservoir.

Aptidão e capacidade da fábrica:

(1) Montagem

Temos uma plataforma de montagem de pesquisa e desenvolvimento independente de primeira classe. A oficina de produção de cilindros hidráulicos tem quatro linhas de montagem semiautomáticas de cilindros de elevação e uma linha de montagem automática de cilindros de inclinação, com uma capacidade de produção anual projetada de 1 milhão de peças. A oficina de cilindros especiais é equipada com várias especificações de um sistema de montagem de limpeza semiautomática com uma capacidade de produção anual projetada de 200.000 peças e equipada com famosos equipamentos de usinagem CNC, um centro de usinagem, um equipamento especial de processamento de cilindros de alta precisão, uma máquina de solda robotizada, uma máquina de limpeza automática, uma máquina de montagem automática de cilindros e uma linha de produção de pintura automática. O equipamento crítico existente é de mais de 300 conjuntos (conjuntos). A alocação ideal e o uso eficiente dos recursos do equipamento garantem os requisitos de precisão dos produtos e atendem às necessidades de alta qualidade dos produtos.

(2) Usinagem

A oficina de usinagem é equipada com um centro de torneamento de trilho inclinado personalizado, um centro de usinagem, uma máquina de brunimento de alta velocidade, um robô de soldagem e outros equipamentos relacionados, que podem lidar com o processamento de tubos de cilindros com diâmetro interno máximo de 400 mm e comprimento máximo de 6 metros.

(3) Soldagem

(4) Pintura e revestimento

Com linhas de revestimento de tinta à base de água automáticas de cilindros de pequeno e médio porte, para obter carregamento e descarregamento automáticos de robôs e pulverização automática, a capacidade projetada é de 4.000 peças por turno;

Também temos uma linha de produção de tinta semiautomática para cilindros grandes, acionada por uma corrente elétrica, com capacidade de projeto de 60 caixas por turno.

(5) Testes

Temos instalações de inspeção e bancos de teste de primeira classe para garantir que o desempenho do cilindro atenda aos requisitos.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding caixas de câmbio agrícolas. Exportamos nossos produtos para clientes em todo o mundo e conquistamos uma boa reputação devido à qualidade superior de nossos produtos e ao serviço pós-venda. Convidamos clientes nacionais e estrangeiros a entrar em contato conosco para negociar negócios, trocar informações e cooperar conosco!

Faça um tour pela nossa fábrica de RV:

Faça um tour pela nossa fábrica de RV com o seguinte

Cilindro hidráulico Aplicação: