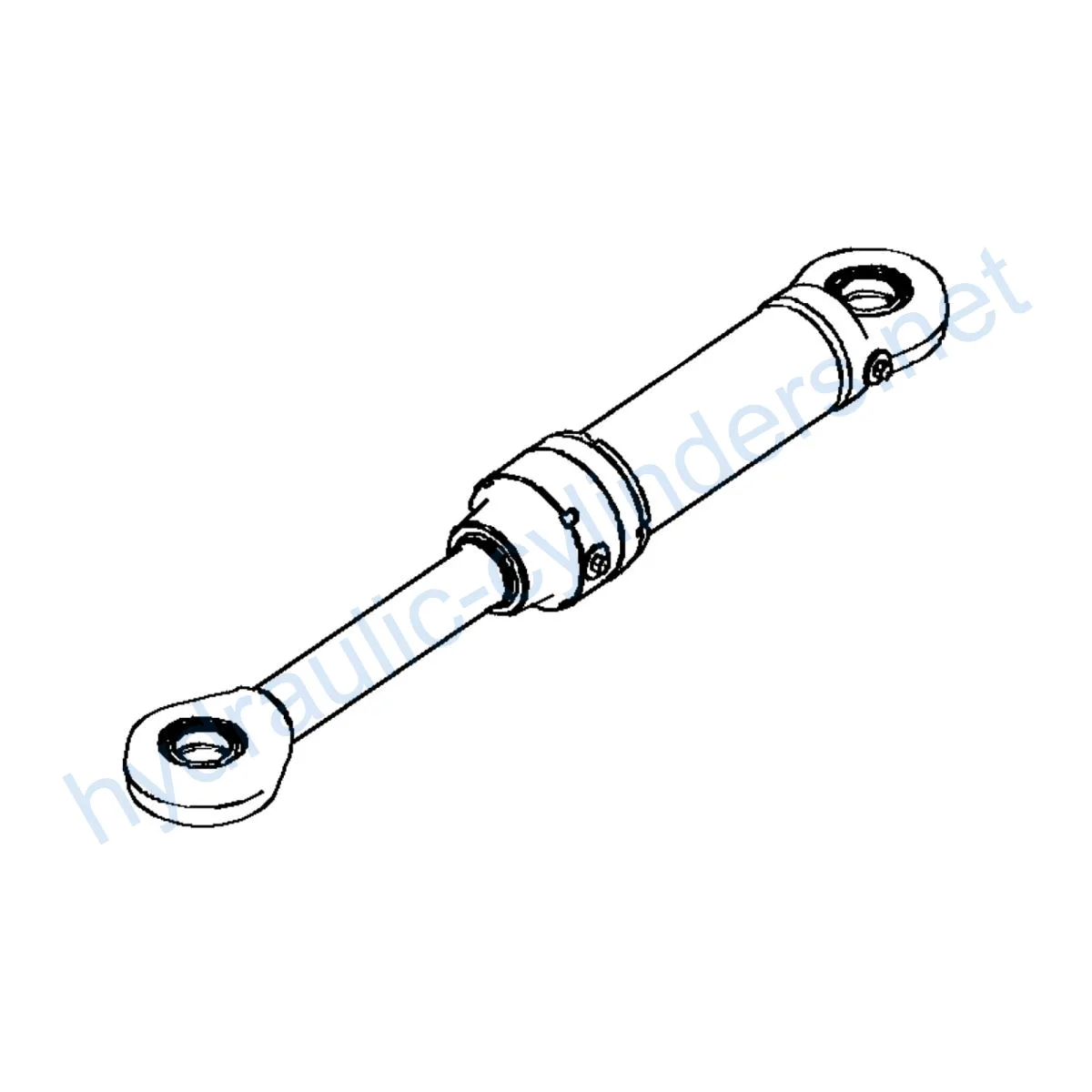

Replacement Of AHC20567 Hydraulic Cylinder

Como um dos fabricantes, fornecedores e exportadores de produtos mecânicos de cilindros hidráulicos, oferecemos cilindros hidráulicos e muitos outros produtos.

Entre em contato conosco para obter detalhes.

Correio eletrônico:sales@hydraulic-cylinders.net

Fabricante, fornecedor e exportador de cilindros hidráulicos.

Replacement Of AHC20567 Hydraulic Cylinder

First, let’s introduce the product and define what this hydraulic cylinder is and its purpose. The AHC20567 Hydraulic Cylinder is a crucial component in various hydraulic systems. It plays a vital role in converting fluid power into mechanical force, allowing for efficient movement and operation of machinery.

Specifications

- Weight: 126.265 lb

- Height: 7 in

- Length: 37 in

Model

The Replacement Of AHC20567 Hydraulic Cylinder is specifically designed for the FL100 model, providing a perfect fit and performance.

Features

- Improved Equipment Performance: Replacing a damaged or worn hydraulic cylinder can restore the normal operation capacity of the equipment, ensuring optimal performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders reduces the risk of safety hazards associated with cylinder failure, ensuring the safety of both operators and equipment.

- Overload Protection: New cylinder designs often incorporate better overload protection mechanisms, elevating safety standards.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts in the market.

We are capable of manufacturing and supplying this product, offering a perfect replacement for these hydraulic cylinders.

Applications

This hydraulic cylinder is used in various equipment and machinery. Here are three examples:

Excavator

In excavators, the hydraulic cylinder on the boom or bucket may get damaged due to prolonged use or overload. Replacement is necessary to restore normal operation.

Crane

The crane’s lifting arm hydraulic cylinder is prone to wear and tear during frequent lifting and lowering processes. Regular replacement is required to ensure safety.

Tractor

The front-end loader hydraulic cylinder on tractors may experience leakage or performance decline due to continuous lifting and tilting operations. Replacement is needed.

These are just a few examples of the many applications where our hydraulic cylinders are vital for efficient and safe operation.

Maintenance Tasks

Regular maintenance is crucial for prolonging the lifespan of hydraulic cylinders. Here are three common maintenance tasks:

Inspeção

Regular inspections are necessary to identify any potential issues or signs of wear and tear. Proper alignment and visual assessments are essential.

Lubrificação

Appropriate lubrication is essential to reduce friction and ensure smooth operation. Using the recommended hydraulic oil and following the lubrication schedule is crucial.

Seal Replacement and Calibration Checks

Periodic seal replacement and calibration checks ensure optimal performance and prevent leakage. Following the recommended procedures is important.

We provide comprehensive maintenance services, including parts replacement and rebuilding, to enhance the longevity of your hydraulic cylinders.

Safety Considerations and Environmental Factors

When using hydraulic cylinders, it is important to prioritize safety measures. Proper handling, following safety guidelines, and using appropriate personal protective equipment are crucial to prevent accidents. Additionally, considering environmental factors and adhering to regulations for waste disposal and fluid management is essential for sustainable operations.

Troubleshooting and Common Issues

Hydraulic cylinders may experience various problems. Here are some common issues:

Leakage

Leakage can occur due to worn seals or damaged components. Proper inspection and seal replacement are necessary to resolve this issue.

Slow Operation

If the hydraulic cylinder operates slowly, it may be due to insufficient lubrication or internal blockages. Lubrication and system flushing can help resolve this issue.

Irregular Movement

Irregular movement can result from misalignment or damaged components. Proper alignment and component replacement are essential for restoring smooth operation.

By following our troubleshooting tips and solutions, readers can effectively diagnose and resolve these issues. It is recommended to implement preventive measures to minimize potential problems.

Design Considerations and Selection Criteria

When selecting hydraulic cylinders, several factors should be considered:

Load-bearing Capacity

The hydraulic cylinder should be selected based on its ability to handle the specific load requirements of the application.

Sealing and Durability

Choosing hydraulic cylinders with high-quality sealing elements, such as piston seals and rod seals made of wear-resistant materials like polyurethane or nitrile rubber, ensures long-lasting performance.

Safety and Maintenance

Designs that prioritize safety features and ease of maintenance contribute to efficient and reliable operation. Cylinders with finely treated cylinder body and threaded ends enhance wear resistance.

Our hydraulic cylinders are designed and manufactured with these considerations in mind, ensuring optimal performance and durability.

Sealing and Lubrication

Hydraulic cylinders require proper sealing and lubrication for optimal performance. Key aspects include:

- Utilizing various sealing components, such as piston seals and rod seals.

- Choosing wear-resistant materials like polyurethane and nitrile rubber for the seals.

- Ensuring precise machining of cylinder bodies and threaded ends to improve wear resistance.

- Regularly adding the appropriate amount of hydraulic oil for lubrication.

Regular Inspection and Preventive Maintenance

To ensure the longevity of hydraulic cylinders, regular inspections and preventive maintenance are essential. Here are some measures:

- Proper installation, lubrication, and adjustment are crucial for optimal cylinder performance.

- Provide guidance on aligning the cylinder correctly during installation.

- Recommend the use of appropriate installation brackets to secure the cylinder.

- Suggest inspection, repair, and replacement procedures to maintain cylinder functionality.

- Offer replacement components and rebuilding services to extend the lifespan of hydraulic cylinders.

- Provide tips to enhance the lifespan of the hydraulic cylinders through proper usage and maintenance.

Product Installation Guide

Correct installation is vital for the proper functioning of hydraulic cylinders. Here are some guidelines:

- Ensure the mounting surface is clean and free from debris.

- Align the cylinder with the mating components accurately.

- Use the recommended torque specifications for fasteners.

- Apply appropriate thread sealant to prevent leaks.

- Verify the cylinder’s stroke and alignment after installation.

Hydraulic Cylinder Maintenance Tasks

Regular maintenance tasks for hydraulic cylinders include inspection, lubrication, seal replacement, and calibration checks. Proper installation, lubrication, and adjustment are crucial for optimal performance. During installation, provide guidance on aligning the cylinder correctly and recommend the use of appropriate installation brackets. We also recommend following

Faça um tour pela nossa fábrica de RV:

Faça um tour pela nossa fábrica de RV com o seguinte

Cilindro hidráulico Aplicação: