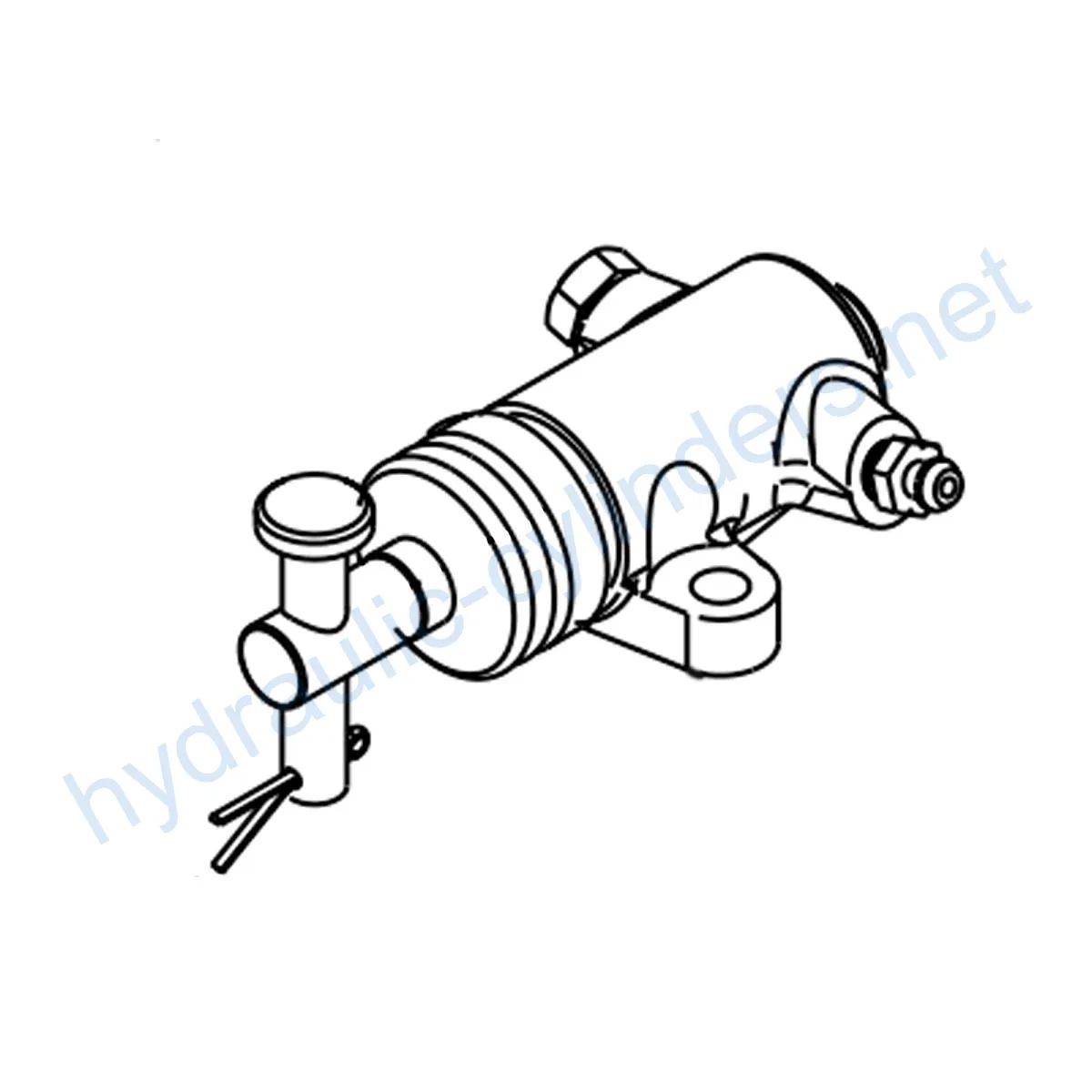

Replacement Of DQ71159 Hydraulic Cylinder

Como um dos fabricantes, fornecedores e exportadores de produtos mecânicos de cilindros hidráulicos, oferecemos cilindros hidráulicos e muitos outros produtos.

Entre em contato conosco para obter detalhes.

Correio eletrônico:sales@hydraulic-cylinders.net

Fabricante, fornecedor e exportador de cilindros hidráulicos.

Replacement Of DQ71159 Hydraulic Cylinder

The Replacement Of DQ71159 Hydraulic Cylinder is a vital component in various types of machinery. It is used to convert the energy of fluid pressure into mechanical force and motion. Its main purpose is to transfer power from one point to another within a hydraulic system. The Replacement Of DQ71159 Hydraulic Cylinder has a weight of 1.26 lb and dimensions of 1.7 in (height) x 6.1 in (width) x 8.3 in (length). It is compatible with the 1165 and 1175 machine models.

Specifications and Models

The Replacement Of DQ71159 Hydraulic Cylinder is designed to withstand the wear and tear of daily use in heavy machinery. It is built to meet the highest industry standards and specifications. The cylinder’s weight, height, width, and length provide the necessary parameters for proper installation. The 1165 and 1175 machine models are the specific models that the cylinder is compatible with.

Features

- Improved Equipment Performance: Replacing damaged or worn-out hydraulic cylinders can restore the equipment’s normal operating capability, ensuring its performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failure, ensuring the safety of operators and equipment.

- Overload Protection: Modern cylinder designs often consider better overload protection mechanisms, improving safety.

- Quick Installation: Modern hydraulic cylinder designs usually consider ease of installation and replacement, reducing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it easy to obtain replacement parts in the market.

Our company provides a perfect replacement for these hydraulic cylinders. We can produce this product with the same quality and specifications as the original one.

Applications

The Replacement Of DQ71159 Hydraulic Cylinder has a wide range of applications. Here are some examples:

- Excavators: Damaged or overloaded hydraulic cylinders in the arm or bucket of an excavator need to be replaced to restore normal operation.

- Cranes: The boom hydraulic cylinder of a crane is prone to wear and tear due to frequent lifting and lowering and requires regular replacement to ensure safety.

- Tractors: The front-end loader hydraulic cylinder of a tractor may leak or suffer from reduced performance due to constant lifting and tilting operations, requiring replacement.

- Harvesters: The hydraulic system of harvesters experiences high pressure, and cylinders may become damaged due to fatigue, requiring timely replacement to maintain work efficiency.

- Automated Production Lines: Hydraulic cylinders are used to control robotic arms and other automation equipment. If the cylinder fails, it affects production efficiency and requires immediate replacement.

- Die Casting Machines: Hydraulic cylinders in die casting machines could experience performance degradation in high-pressure and high-temperature environments. Regular replacement ensures product quality.

- Mining Equipment: Hydraulic cylinders are used to lift and move heavy loads in mining equipment. Due to the harsh working environment, regular inspection and replacement are necessary to avoid equipment failure.

- Bulldozers: The wear of hydraulic cylinders on the push arm of a bulldozer may lead to a decrease in the bulldozer’s pushing ability, necessitating timely replacement to maintain operational efficiency.

Maintenance Tasks

Regular maintenance tasks are necessary to ensure the proper functioning of the Replacement Of DQ71159 Hydraulic Cylinder. Here are some common tasks:

- Periodic Inspection: Regular visual inspection of the cylinder’s seals, rods, and other components is necessary to detect signs of wear and tear.

- Lubrication: Proper lubrication of the cylinder’s moving parts is necessary to prevent friction and damage.

- Seal Replacement: Damaged seals can result in oil leaks and reduced performance and require replacement.

- Calibration Check: Regular calibration checks are necessary to ensure the cylinder operates within the required range and specifications.

Correct installation, lubrication, and adjustment are crucial maintenance tasks. During installation, proper alignment of the cylinder is necessary, and the use of suitable installation brackets is recommended. We also offer inspection, repair, and replacement services, as well as tips for increasing the lifespan of the Replacement Of DQ71159 Hydraulic Cylinder.

Safety and Environmental Considerations

The Replacement Of DQ71159 Hydraulic Cylinder has safety considerations that should be taken seriously. Proper safety protocols and protective gear should be used when handling and installing the cylinder. Environmental factors should also be considered, such as proper disposal of old cylinders and hydraulic fluid.

Diagnosis and Troubleshooting

Common problems with hydraulic cylinders can be diagnosed and solved with proper troubleshooting techniques. Here are some troubleshooting tips:

- Noise: If the cylinder is making noise, it may indicate worn-out seals or rods, and they may need replacement.

- Leakage: Oil leaks are a common issue with hydraulic cylinders and may indicate seal damage or improper installation.

- Slow Movement: Slow cylinder movement may be caused by insufficient lubrication or a blockage in the hydraulic system.

Preventive measures such as regular inspection and maintenance can help reduce potential problems. It is also essential to follow proper maintenance guidelines to avoid issues in the future.

Design Considerations and Selection Criteria

When selecting a hydraulic cylinder, it is essential to consider its design and selection criteria.

- Load-Bearing Capacity: The cylinder’s load-bearing capacity is a crucial factor to consider when selecting a hydraulic cylinder.

- Sealing: Proper sealing of the cylinder’s components is necessary to prevent leaks and ensure performance.

- Durability: Hydraulic cylinders should be built to withstand harsh operating conditions and have a long lifespan.

- Safety: Safety features are necessary to ensure that the cylinder operates safely and avoids hazards from leaks and other issues.

- Maintainability: Hydraulic cylinders should be designed to be easily maintained and repaired, reducing downtime and operational costs.

Sealing and Lubrication

The selection of the proper sealing and lubrication is vital to ensure the longevity and performance of the hydraulic cylinder. Proper sealing and lubrication can be achieved with various seals and lubrication techniques. The cylinder’s piston seals, rod seals, and other components should be made of durable materials that are resistant to wear and tear. The cylinder should be lubricated with suitable hydraulic oil, which should be changed regularly to prevent contamination and ensure proper lubrication.

Installation Guide

Proper installation of the Replacement Of DQ71159 Hydraulic Cylinder is essential to ensure proper operation and prevent safety hazards. Here are some installation guidelines:

- Proper Alignment: Proper alignment is necessary to ensure that the cylinder operates smoothly and avoids problems caused by misalignment.

- Use of Installation Brackets: The use of installation brackets is recommended to provide proper support and alignment during installation.

- Inspection and Testing: After installation, the hydraulic system should be inspected and tested to ensure proper operation and safety.

About Our Company

Our company is a leading manufacturer and wholesaler of hydraulic cylinders, providing a broad range of cylinders to meet the needs of the domestic and international markets. Our company offers professional services, international certification, customized products, advanced production equipment, and excellent after-sales service.

We strive to provide our customers with the highest quality products and services, ensuring that our hydraulic cylinders meet the most stringent standards and specifications. Our company has a strong commitment to innovation, and we are constantly developing new products and technologies to meet the evolving needs of our customers.

Author: lyl

Faça um tour pela nossa fábrica de RV:

Faça um tour pela nossa fábrica de RV com o seguinte

Cilindro hidráulico Aplicação: