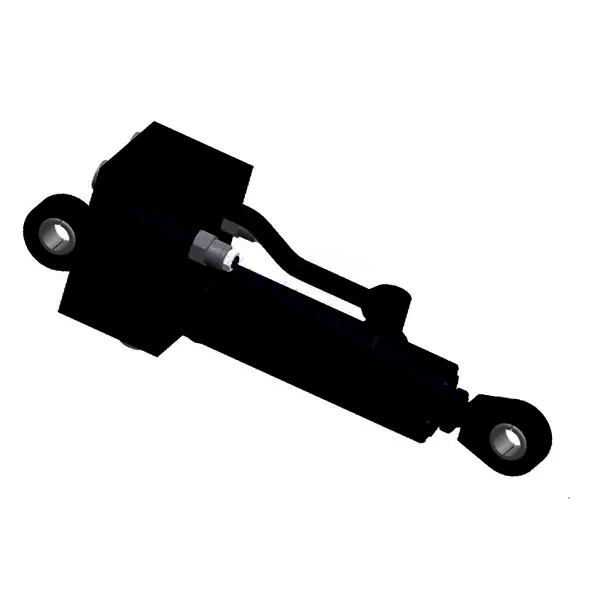

Ro-ro Platform Latch Cylinders (hydraulic self-locking)

Fiind unul dintre producătorii, furnizorii și exportatorii de cilindri hidraulici, oferim cilindri hidraulici și multe alte produse.

Vă rugăm să luați legătura cu noi pentru detalii.

Mail:sales@hydraulic-cylinders.net

Producător, furnizor, exportator de cilindri hidraulici.

Ro-ro Platform Latch Cylinders (hydraulic self-locking)

Ro-ro platform latch cylinders with hydraulic self-locking capabilities are essential components designed to enhance the safety and efficiency of roll-on/roll-off (ro-ro) operations. These innovative hydraulic cylinders provide a reliable and convenient locking mechanism to secure the platform during transportation, preventing unwanted movement and ensuring the safe delivery of goods. With their exceptional features and hydraulic self-locking mechanism, ro-ro platform latch cylinders are the ultimate solution for companies seeking enhanced security and streamlined logistics.

Ro-ro platform latch cylinders with hydraulic self-locking capabilities provide the utmost security and efficiency in ro-ro operations. With their hydraulic self-locking mechanism, robust construction, and easy integration, these cylinders ensure safe and streamlined transportation of goods. By following the recommended usage methods and implementing regular maintenance practices, companies can maximize the longevity and performance of these essential components, contributing to enhanced security and smooth logistics operations.

Ro-ro Platform Latch Cylinders (hydraulic self-locking) Key Characteristics:

- Hydraulic Self-Locking: Ro-ro platform latch cylinders feature a hydraulic self-locking mechanism that securely locks the platform once engaged. This eliminates the need for external locking devices, reducing complexity and increasing operational efficiency.

- Robust Construction: These cylinders are built with high-quality materials to withstand the demanding conditions of ro-ro operations. Their robust construction ensures durability and longevity, minimizing downtime and maintenance costs.

- Easy Integration: Ro-ro platform latch cylinders are designed for easy integration into existing ro-ro platform systems. They can be seamlessly installed and retrofitted, enabling quick and hassle-free implementation.

- Enhanced Safety: The hydraulic self-locking mechanism of these cylinders ensures that the platform remains securely locked during transportation. This feature significantly reduces the risk of accidents, preventing cargo shifts and enhancing overall safety.

Ro-ro Platform Latch Cylinders (hydraulic self-locking) Parameter:

| Product Name | Ro-ro Platform Latch Cylinder |

| Features: | Lock the bolt after the springboard or ramp is recovered in place |

| Specification: | Specifications: 80/50*S, 63/40*S, 40/28*S,front and rear Having DNVGL type approval With standard size series selection |

| Pressure | 25MPa (stainless steel piston rod) |

| Applications: | Ro-ro Platform |

Having DNVGL type approval

With standard size series selection

(stainless steel piston rod)

Ro-ro Platform Main Operating Cylinder Application:

Usage Method Of Ro-ro Platform Latch Cylinders (hydraulic self-locking):

- Installation: Ro-ro platform latch cylinders are installed strategically on the ro-ro platform. Mount the cylinders securely using appropriate brackets and hardware, ensuring proper alignment and clearance for operation.

- Activation: Once the platform is positioned and ready for transport, activate the hydraulic self-locking mechanism. This can be achieved through manual engagement or automated systems, depending on the specific design and requirements.

- Locking Verification: After engaging the self-locking mechanism, verify that the cylinders are securely locked and holding the platform. Perform visual inspections and functional tests to ensure proper engagement and functionality.

How Do Rephasing Hydraulic Cylinders Work?

The basic principle behind rephasing hydraulic cylinders is using interconnected fluid lines that allow for transferring hydraulic fluid between the cylinders. This interconnection enables the cylinders to share the load and maintain equal stroke lengths, regardless of variations in the bag or resistance encountered by each cylinder.

Here’s a step-by-step breakdown of how rephasing hydraulic cylinders works:

- Interconnected Fluid Lines: Rephasing cylinders are connected through fluid lines or passages. These lines allow hydraulic fluid to flow between the cylinders, creating a shared hydraulic system.

- Initial Positioning: The cylinders are initially positioned at the same starting point. This ensures they have the same starting stroke length and are ready to move in unison.

- Hydraulic Fluid Transfer: As hydraulic fluid is pumped into the system, it flows through the interconnected lines. The fluid pressure causes the cylinders to extend, and the liquid is distributed between the cylinders, maintaining equal pressure throughout the system.

- Load Distribution: When a load is applied to the rephasing cylinders, each cylinder experiences different resistance levels or forces. The cylinders with less resistance will extend further, while those with more resistance will extend less. This difference in extension causes the hydraulic fluid to flow from the more extended cylinder to the less comprehensive cylinder through the interconnected lines.

- Equalizing Stroke Lengths: The stroke lengths begin to equalize as the hydraulic fluid transfers between the cylinders. The cylinders adjust their extension levels until the load is distributed evenly, resulting in synchronized movement and equal stroke lengths.

- Balanced Force: Once the stroke lengths are equalized, the rephasing cylinders exert equal force on the load. This ensures balanced force distribution and prevents uneven loading or tilting of the system.

- Simultaneous Retraction: When the hydraulic system is reversed, or the cylinders need to retract, the fluid flow is reversed. The fluid is transferred back to the retracting cylinders, ensuring synchronized retraction and equal stroke lengths.

Capabilitatea și capacitatea fabricii:

(1) Montaj

Avem o platformă de asamblare independentă de cercetare și dezvoltare de primă clasă. Atelierul de producție a cilindrilor hidraulici are patru linii de asamblare semiautomate pentru cilindri de ridicare și o linie de asamblare automată a cilindrilor de înclinare, cu o capacitate de producție anuală proiectată de 1 milion de bucăți. Atelierul de cilindri speciali este echipat cu diverse specificații ale unui sistem de asamblare semi-automat de curățare, cu o capacitate de producție anuală proiectată de 200.000 și dotat cu echipamente celebre de prelucrare CNC, un centru de prelucrare, un echipament special de prelucrare a cilindrilor de înaltă precizie, o mașină de sudură robotizată, o mașină de curățare automată, o mașină de asamblare automată a cilindrilor și o linie de producție automată de vopsire. Echipamente critice existente de peste 300 de seturi (seturi). Alocarea optimă și utilizarea eficientă a resurselor de echipamente asigură cerințele de precizie ale produselor și satisface nevoile de înaltă calitate ale produselor.

(2) Prelucrare

Atelierul de prelucrare este echipat cu un centru de strunjire cu șină înclinată personalizat, un centru de prelucrare, o mașină de honuire de mare viteză, un robot de sudură și alte echipamente conexe, care pot gestiona prelucrarea tuburilor cilindrice cu un diametru interior maxim de 400 mm și o lungime maximă de 6 metri.

(3) Sudură

(4) Vopsire și acoperire

Cu linii automate de acoperire cu vopsea pe bază de apă cu cilindru de dimensiuni mici și medii, pentru a realiza încărcarea și descărcarea automată a robotului și pulverizarea automată, capacitatea de proiectare de 4000 de bucăți pe schimb;

Avem, de asemenea, o linie de producție semi-automată de vopsire pentru cilindri mari, acționată de un lanț de putere, cu o capacitate de proiectare de 60 de cutii pe schimb.

(5) Testarea

Dispunem de instalații de inspecție și bancuri de testare de primă clasă pentru a ne asigura că performanța cilindrului îndeplinește cerințele.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding cutii de viteze agricole. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and să coopereze cu noi!

Faceți un tur al fabricii noastre VR:

Faceți un tur al fabricii noastre VR cu următoarele

Cilindru hidraulic Aplicație: