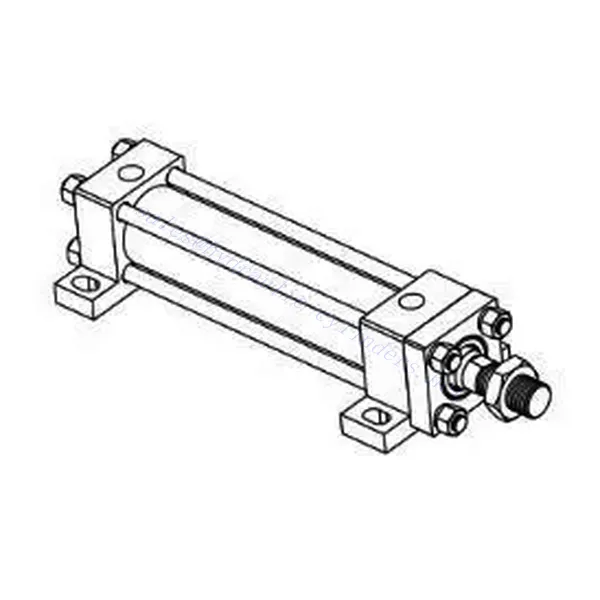

LA Stânga și dreapta picior de tip Heavy Rod cilindru hidraulic

Fiind unul dintre producătorii, furnizorii și exportatorii de cilindri hidraulici, oferim cilindri hidraulici și multe alte produse.

Vă rugăm să luați legătura cu noi pentru detalii.

Mail:sales@hydraulic-cylinders.net

Producător, furnizor, exportator de cilindri hidraulici.

LA Stânga și dreapta picior de tip Heavy Rod cilindru hidraulic

The LA left and right foot heavy rod hydraulic cylinder is a cutting-edge hydraulic element designed to meet the needs of various industrial applications. With its rugged construction, superior force output, and unique left and right foot design, this hydraulic cylinder offers exceptional power, precision, and versatility. Whether heavy lifting, pushing, or pulling, LA left and right foot type heavy-duty rod hydraulic cylinders provide reliable performance to optimize industrial operations.

Essential Characteristics Of Heavy Rod Hydraulic Cylinder:

Robust Construction: Using high-quality materials such as solid steel or alloys, LA left and right foot type heavy rod hydraulic cylinders ensure durability and longevity. Its rugged construction allows it to handle heavy loads, high pressures, and challenging environmental conditions, making it suitable for demanding industrial tasks.

High Force Output: This hydraulic cylinder boasts impressive force output, making it ideal for applications requiring substantial power. Its large piston diameter and high-pressure capabilities provide exceptional strength to handle heavy-duty tasks easily.

Left and Right Foot Design: The LA left and right foot heavy rod hydraulic cylinder has a unique left and right foot design that allows for various mounting options. This design is easy to install and integrate into multiple hydraulic systems and equipment configurations, providing flexibility and adaptability.

Precise Control: Equipped with precision machined components and high-quality seals, this hydraulic cylinder ensures accurate and reliable operation. It can precisely control the movement and positioning of loads for efficient and appropriate processing.

LA Left And Right Foot Type Heavy Rod Hydraulic Cylinder Parameter:

LA Stânga și dreapta picior de tip Heavy Rod cilindru hidraulic Usage Method:

Mounting: Start by safely installing the LA left and right foot weight rod hydraulic cylinders using appropriate brackets or fixtures. Ensure proper alignment and stability during installation to prevent cylinder misalignment or stress.

Hydraulic System Integration: Connect hydraulic lines to cylinder ports per manufacturer’s instructions and guidelines. Integrate the cylinder into the hydraulic system by clicking on the appropriate pump or power unit. Ensure cylinder specifications and operating requirements are met.

Control and Operation: The control valve in the hydraulic system regulates the flow of hydraulic oil into and out of the cylinder. Adjust the control Settings according to the desired linear motion and force output. Test the movement of the cylinder to verify its function and responsiveness.

LA Stânga și dreapta picior de tip Heavy Rod cilindru hidraulic Maintenance:

Regular maintenance ensures optimal performance and longevity of the LA left and right foot type heavy rod hydraulic cylinder. Follow these maintenance guidelines:

Inspecție periodică: Perform routine inspections to identify signs of wear, damage, or leaks. Check for abnormalities in cylinder blocks, piston rods, seals, and other components. Resolve any issues promptly to prevent further injury or operational inefficiencies.

Lubrifiere: Apply the recommended lubricant to the moving parts of the cylinder, including tie rods and seals. Regular lubrication minimizes friction, reduces wear, and ensures smooth operation. Use the appropriate lubricant type according to the manufacturer’s lubrication interval guidelines.

Seal Replacement: If seals are found to be deteriorating or leaking, replace seals with genuine parts approved by the manufacturer. Damaged or worn seals can compromise the cylinder’s performance and lead to hydraulic oil leakage.

Cleaning: Clean cylinders by removing dirt, debris, and other contaminants. Before reassembling, use a non-abrasive cleaner and make sure all parts are arid. Regular cleaning promotes optimal performance and prevents premature wear or damage.

How To Control Hydraulic Cylinder Speed?

Controlling the speed of a hydraulic cylinder is essential to ensure safe and efficient operation in various applications. There are several methods to control the speed of a hydraulic cylinder, including the following:

- Flow Control Valves: Flow control valves are commonly used to regulate the speed of hydraulic cylinders. These valves control the flow rate of hydraulic fluid entering or exiting the cylinder, thereby controlling the cylinder’s speed. There are two types of flow control valves:a. Throttle Valves: Throttle valves restrict the flow of hydraulic fluid by creating a narrow passage. They regulate the speed by controlling fluid flow through the valve. Throttle valves are often adjustable, allowing for precise speed control.b. Needle Valves: Needle valves have a tapered needle-like plunger that can be adjusted to restrict or allow fluid flow. By adjusting the position of the needle, the flow rate and, consequently, the cylinder speed can be controlled.

- Proportional Control Valves: Proportional control valves offer more precise control over the speed of hydraulic cylinders. These valves modulate the flow of hydraulic fluid based on electrical or electronic signals, allowing for fine adjustment of the cylinder’s speed. Proportional control valves are often used in applications where precise speed control is critical, such as in automation systems.

- Variable Displacement Pumps: In some hydraulic systems, variable displacement pumps control the speed of hydraulic cylinders. These pumps adjust the volume of fluid delivered to the cylinder, thereby regulating the cylinder speed. By changing the pump’s displacement or stroke volume, the speed of the cylinder can be adjusted accordingly.

- Load-Sensing Systems: Load-sensing systems are advanced hydraulic systems that adjust the pump’s output to match the load requirements. These systems monitor the pressure in the hydraulic circuit and adjust the pump’s displacement accordingly. By maintaining a constant pressure, load-sensing systems can regulate the cylinder speed even under varying load conditions.

- Accumulators: Hydraulic accumulators can be used to control the speed of hydraulic cylinders in specific applications. An accumulator stores hydraulic fluid under pressure, which can be released to supplement the flow from the pump. By controlling fluid release from the accumulator, the speed of the cylinder can be adjusted.

- Gearboxes or Transmission Systems: In some cases, mechanical gearboxes or transmission systems can be employed to indirectly control the speed of hydraulic cylinders. By adjusting the gear ratio or transmission settings, the rotational speed of the input shaft can be translated into the desired speed for the hydraulic cylinder.

Capabilitatea și capacitatea fabricii:

(1) Montaj

Avem o platformă de asamblare independentă de cercetare și dezvoltare de primă clasă. Atelierul de producție a cilindrilor hidraulici are patru linii de asamblare semiautomate pentru cilindri de ridicare și o linie de asamblare automată a cilindrilor de înclinare, cu o capacitate de producție anuală proiectată de 1 milion de bucăți. Atelierul de cilindri speciali este echipat cu diverse specificații ale unui sistem de asamblare semi-automat de curățare, cu o capacitate de producție anuală proiectată de 200.000 și dotat cu echipamente celebre de prelucrare CNC, un centru de prelucrare, un echipament special de prelucrare a cilindrilor de înaltă precizie, o mașină de sudură robotizată, o mașină de curățare automată, o mașină de asamblare automată a cilindrilor și o linie de producție automată de vopsire. Echipamente critice existente de peste 300 de seturi (seturi). Alocarea optimă și utilizarea eficientă a resurselor de echipamente asigură cerințele de precizie ale produselor și satisface nevoile de înaltă calitate ale produselor.

(2) Prelucrare

Atelierul de prelucrare este echipat cu un centru de strunjire cu șină înclinată personalizat, un centru de prelucrare, o mașină de honuire de mare viteză, un robot de sudură și alte echipamente conexe, care pot gestiona prelucrarea tuburilor cilindrice cu un diametru interior maxim de 400 mm și o lungime maximă de 6 metri.

(3) Sudură

(4) Vopsire și acoperire

Cu linii automate de acoperire cu vopsea pe bază de apă cu cilindru de dimensiuni mici și medii, pentru a realiza încărcarea și descărcarea automată a robotului și pulverizarea automată, capacitatea de proiectare de 4000 de bucăți pe schimb;

Avem, de asemenea, o linie de producție semi-automată de vopsire pentru cilindri mari, acționată de un lanț de putere, cu o capacitate de proiectare de 60 de cutii pe schimb.

(5) Testarea

Dispunem de instalații de inspecție și bancuri de testare de primă clasă pentru a ne asigura că performanța cilindrului îndeplinește cerințele.

We are one of the best heavy rod hydraulic cylinder manufacturers. We can offer wide heavy rod hydraulic cylinder stock. We also provide corresponding cutii de viteze agricole. Am exportat produsele noastre către clienți din întreaga lume și am câștigat o bună reputație datorită calității superioare a produselor noastre și a serviciilor post-vânzare. Salutăm călduros clienții atât din țară, cât și din străinătate să ne contacteze pentru a negocia afaceri, a face schimb de informații și a să coopereze cu noi!

Faceți un tur al fabricii noastre VR:

Faceți un tur al fabricii noastre VR cu următoarele

Cilindru hidraulic Aplicație: