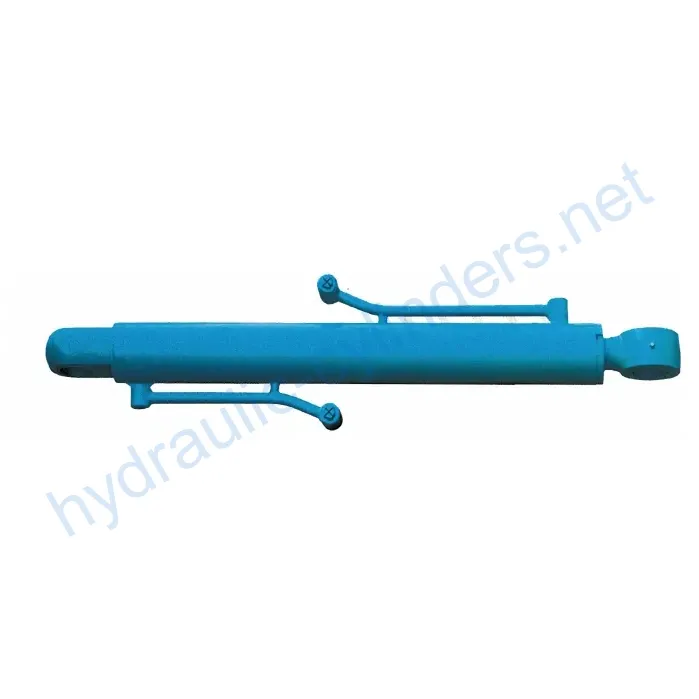

Bucket Cylinder For JCM Small Excavator 906D

Fiind unul dintre producătorii, furnizorii și exportatorii de cilindri hidraulici, oferim cilindri hidraulici și multe alte produse.

Vă rugăm să luați legătura cu noi pentru detalii.

Mail:sales@hydraulic-cylinders.net

Producător, furnizor, exportator de cilindri hidraulici.

Bucket Cylinder For JCM Small Excavator 906D

Introduction

The Bucket Cylinder for JCM Small Excavator 906D is a specially designed hydraulic cylinder used primarily to control the movement of the bucket in heavy machinery such as excavators, backhoe excavators, and front-end loaders. Its main function is to enable the bucket to lift, lower, and tilt, making it easier to handle all kinds of material moving tasks. In the hydraulic system, the bucket cylinder precisely controls the bucket’s movement by changing the pressure of hydraulic oil, allowing operators to handle heavy loads efficiently and adapt to complex work environments and diverse operational requirements.

Features

- High strength and durability: Typically made from high-strength steel or aluminum, the cylinder can withstand high pressure and heavy loads, adapt to harsh work environments, and its design considers wear and corrosion resistance, extending its service life.

- Efficient hydraulic operation: By utilizing the pressure of hydraulic oil, the cylinder can smoothly extend and retract, respond quickly to control commands, provide powerful pushing and pulling forces, suitable for handling heavy loads and complex operational tasks.

- Various types: The cylinder can be a single-acting (hydraulic is used only in one direction) or double-acting (hydraulic is used in both directions) cylinder, depending on the operational requirements. Some models are telescopic, allowing greater extension without increasing the external dimensions, making it suitable for applications with limited space.

- Our product can perfectly replace these hydraulic cylinders.

Applications

The Bucket Cylinder for JCM Small Excavator 906D is widely used in various industries for different applications. Here are some of them:

Construction Equipment

In excavators, they are essential for excavation, loading, and movement of soil or debris. In a backhoe excavator, the bucket cylinder helps with excavation and lifting. In front-end loaders, they assist in lifting and dumping goods efficiently.

Agricultural Machinery

Used in front-end loaders to scoop, lift, and transport soil, hay, and other materials. In excavators, the bucket cylinder allows excavation by allowing the bucket to penetrate the soil.

Industrial Manufacturing

They are used in various manufacturing processes, such as die casting, forging, and plastic injection molding, to handle heavy loads and carry out complex operational tasks.

Marine and Offshore

Bucket cylinders are used in offshore oil drilling platforms, container ships, and other marine equipment, where they can withstand harsh environmental conditions and perform heavy-duty tasks.

Design Considerations and Selection Criteria

Bucket cylinders need to meet several design considerations and selection criteria to ensure optimal performance. Here are some of them:

Bearing capacity

The cylinder must be able to withstand the weight of the load it carries and the pressure exerted on it during operation.

Sealing

The cylinder must have adequate sealing to prevent oil leaks and contamination, which can cause damage to the system and reduce performance.

Durability

The cylinder must be durable enough to withstand harsh working conditions and frequent use without requiring frequent repairs or replacements.

Safety

The cylinder must be designed with safety considerations in mind, such as installing safety valves to prevent accidents and providing clear instructions for installation and operation.

Maintenance

The cylinder must be easy to maintain, with proper access points for inspection, cleaning, and replacement of parts.

Sealing and Lubrication

The bucket cylinder uses various sealing components, such as piston seals, rod seals, and wipers, to prevent oil leaks and contamination. These sealing components are made of wear-resistant materials such as polyurethane and nitrile rubber to ensure long service life. Additionally, the cylinder’s cylinder body and threaded end surface undergo fine processing to improve wear resistance. To maintain optimal performance, regular lubrication with the right amount of hydraulic oil is necessary.

Maintenance and Repair

Regular maintenance and repair are essential to ensure the bucket cylinder’s optimal performance and extend its service life. Here are some essential tasks:

Regular Inspection

Regularly inspect the cylinder, looking for signs of wear and damage, such as leaks, dents, and rust.

Lubrication

Proper lubrication with hydraulic oil is necessary to ensure optimal performance.

Seal Replacement

Replace worn or damaged seals promptly to prevent oil leaks and contamination and ensure optimal performance.

Calibration Check

Regularly check the cylinder’s calibration to ensure it meets the required specification.

Safety Considerations and Environmental Factors

Bucket cylinders can be dangerous if not used correctly or if installed inappropriately. Safety measures, such as providing clear instructions for installation, operation, and maintenance, must be followed. Additionally, consideration must be given to environmental factors, such as temperature, humidity, and exposure to corrosive materials, to ensure optimal performance and extend the cylinder’s service life.

Common Problems and Troubleshooting

Common problems with bucket cylinders can include leaks, inadequate pressure, and damage due to wear and tear. Troubleshooting these problems involves identifying the cause and taking appropriate corrective measures, such as resealing, replacing damaged parts, and recalibrating the cylinder. Regular maintenance and repair can help prevent many of these problems.

About Our Company

We are a manufacturer of replacement hydraulic cylinders with a complete range of products, and have become one of the leading manufacturers and wholesale distributors of hydraulic cylinders in domestic and international markets. We adhere to the principle of excellence in quality and rely on industrialized production management strategies in finely crafted manufacturing workshops. We continuously improve the manufacturing platform of our workshop, perfect our product quality production line, and have a strong ability to create a high-efficiency, high-precision, and high-quality principle to meet customers’ diverse needs.

Professionalism

Our company is staffed by a team of experienced professionals who are dedicated to delivering high-quality products and services to our customers.

International Certification

Our products are certified to international standards, such as ISO 9001 and CE, ensuring that they meet the highest quality standards.

Customization Services

We provide customization services to meet customers’ unique requirements, such as size, shape, and functionality.

Production Equipment

Our workshop is equipped with high-end digital manufacturing equipment, including CNC machines, lathes, and grinders, to ensure precise product specifications.

After-Sales Service

We provide comprehensive after-sales services, including installation, repair, and maintenance, to ensure our customers are satisfied with our products.

Author: lyl.

Faceți un tur al fabricii noastre VR:

Faceți un tur al fabricii noastre VR cu următoarele

Cilindru hidraulic Aplicație: