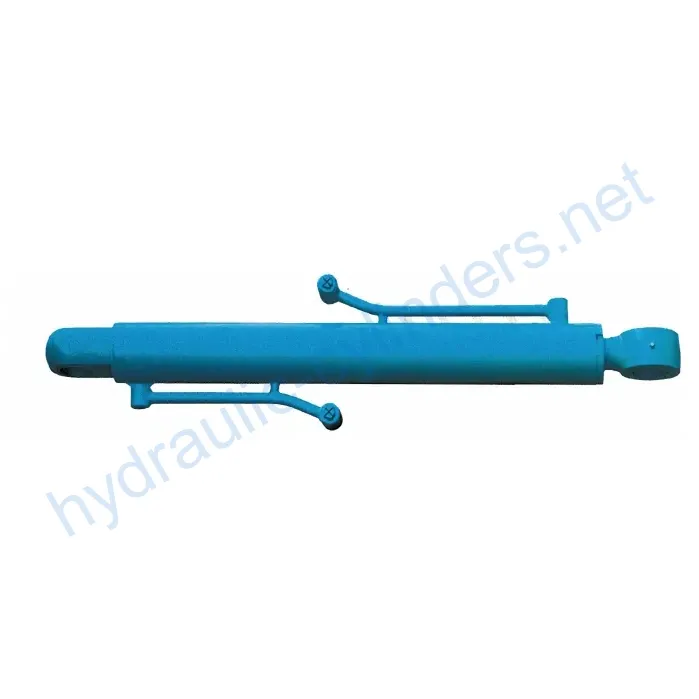

Bucket Cylinder For Takeuchi Small Excavator TB153FR

Introduction

A bucket cylinder is a specifically designed hydraulic cylinder primarily used to control the movement of the bucket in heavy machinery such as excavators, backhoes, and front-end loaders. Its main function is to enable the bucket to lift, lower, and tilt, making it easier to handle various material handling tasks. In the hydraulic system, the bucket cylinder precisely controls the bucket’s movements through the pressure changes in hydraulic oil, allowing operators to efficiently handle heavy loads and adapt to complex work environments and diverse job requirements.

Product Features

- High strength and durability: Usually made of high-strength steel or aluminum, it can withstand high pressure and heavy loads, adapt to harsh working environments, and designed with wear resistance and corrosion resistance to extend its service life.

- Efficient hydraulic operation: Smooth telescopic movements are achieved with the help of hydraulic oil pressure, enabling quick response to control commands, providing powerful pushing and pulling force, and suitable for handling heavy loads and complex job tasks.

- Various types: Single-acting (hydraulic is used in only one direction) or double-acting (hydraulic is used in both directions) cylinders can be selected according to requirements to meet different operating needs. Some models are telescopic, allowing for greater extension without increasing external dimensions, suitable for applications with limited space.

- Replaceable product: Our products can perfectly replace these hydraulic cylinders.

Application of Bucket Cylinder

Bucket cylinders are widely used in various heavy machinery, including:

- Construction equipment: In excavators, they are essential for digging, loading, and moving soil or debris. In backhoes, bucket cylinders assist in both digging and lifting.

- Agricultural machinery: Used on front-end loaders to scoop, lift, and transport soil, hay, and other materials.

- Excavators: Bucket cylinders enable digging actions by allowing the bucket to penetrate the soil.

- Loaders: In front-end loaders, they assist in lifting and tilting goods effectively.

Let’s take a closer look at each application:

Construction Equipment

In excavators, bucket cylinders are one of the most important components. They play a critical role in digging, loading, and moving soil or debris.

Agricultural Machinery

Bucket cylinders are commonly used in agricultural machinery to assist in various material handling tasks. They are used on front-end loaders to scoop, lift, and transport soil, hay, and other materials.

Excavators

Bucket cylinders enable excavating actions by allowing the bucket to penetrate the soil. They are an essential part of any excavator.

Loaders

Bucket cylinders play a critical role in front-end loaders. They assist in lifting and tilting goods effectively.

Design Considerations and Selection Criteria

When designing bucket cylinders, several critical factors must be considered:

- Bearing capacity: Bucket cylinders must be able to withstand high loads and pressure.

- Sealing: Bucket cylinders require excellent sealing performance to prevent leakage and ensure reliable operation.

- Durability: Bucket cylinders are expected to operate in harsh environments and should be durable and robust.

- Safety: Bucket cylinders must be designed with safety in mind, ensuring that they do not pose any risks to operators or the surrounding environment.

- Maintenance: Bucket cylinders should be easy to maintain and repair, reducing downtime and maintenance costs.

Sealing and Lubrication

Bucket cylinders use various sealing components, such as piston seals and rod seals, selected based on their ability to withstand wear and heat. Sealing components are usually made of materials such as polyurethane and nitrile rubber. The cylinder body and threaded end surfaces are finely processed to improve wear resistance. Regular lubrication with hydraulic oil is essential to keep the bucket cylinder functioning correctly and extend its service life.

Maintenance and Repair

To maintain bucket cylinders, it is recommended to perform the following tasks regularly:

- Check for leaks and damaged seals

- Ensure the bucket cylinder’s mounting points are secure

- Check the hydraulic hoses for signs of damage or wear

Proper installation, lubrication, and adjustment are essential to ensure the bucket cylinder operates correctly and extends its service life. Use proper alignment and appropriate mounting brackets to secure the cylinder.

Safety Considerations and Environmental Factors

Safety is critical when working with bucket cylinders. Operators should follow safety guidelines and wear appropriate personal protective equipment when working with bucket cylinders.

Bucket cylinders are designed with the environment in mind and must meet environmental regulations and standards.

Failure Diagnosis and Troubleshooting

In case of bucket cylinder failure, the following troubleshooting steps can be taken:

- Check for leaks and signs of damage or wear on sealing components

- Check the hydraulic hoses for signs of damage or wear

- Check the mounting points for damage or looseness

Preventative measures such as regular maintenance and proper installation can help minimize potential issues.

About Our Company

We are a manufacturer of hydraulic cylinders that can replace traditional hydraulic cylinders. Our company offers a wide range of products and has become one of the leading manufacturers and wholesale distributors of hydraulic cylinders in domestic and international markets. We adhere to the principle of excellent quality, rely on the industrial production management strategy of the refined manufacturing workshop, continuously improve the manufacturing platform, improve the production quality, and have a strong creation ability. We provide customers with efficient, high-precision, and high-quality products to meet diverse customer needs.

Our company is characterized by our professionalism, international certification, customization service, production equipment, and after-sales services.

Author: lyl.