HROC Cilindru hidraulic circular de tip trunnion unic HROC

Fiind unul dintre producătorii, furnizorii și exportatorii de cilindri hidraulici, oferim cilindri hidraulici și multe alte produse.

Vă rugăm să luați legătura cu noi pentru detalii.

Mail:sales@hydraulic-cylinders.net

Producător, furnizor, exportator de cilindri hidraulici.

HROC Cilindru hidraulic circular de tip trunnion unic HROC

The HROC single trunnion type circular hydraulic cylinder is a cutting-edge hydraulic element designed to provide reliable and efficient power transmission for a variety of industrial applications. With its innovative design and superior performance, this hydraulic cylinder offers precise control, durability, and versatility. Whether in manufacturing, construction, or material handling, HROC single trunnion-type cylinders are designed to optimize the hydraulic operation and increase productivity.

HRO series round cylinder safe and stable, output, easy maintenance, beautiful appearance, high quality, suitable for all kinds of press.

HROA Type Circular Hydraulic Cylinder Characteristic Data:

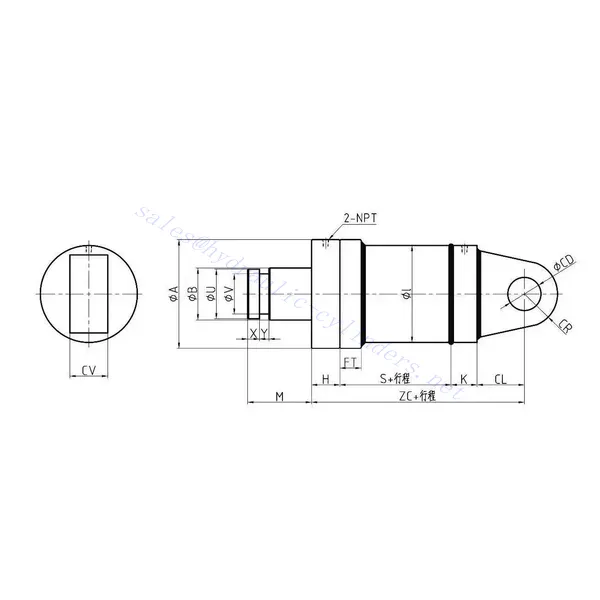

HROA Type Circular Hydraulic Cylinder Structure Diagram:

HROC Single Trunnion Type Circular Hydraulic Cylinder Parameter:

HROC Cilindru hidraulic circular de tip trunnion unic HROC External Tooth Type Specification Sheet:

HROC Cilindru hidraulic circular de tip trunnion unic HROC Usage Method:

- Mounting and Installation:

- Determine the appropriate installation location for HROC single trunnion cylinders based on the specific requirements of your equipment or machine.

- Ensure that the mounting surface is firm level and can safely support the weight and load of the cylinder.

- Hydraulic System Connection:

- Connect the hydraulic cylinder to the hydraulic system using a compatible hydraulic hose or pipe.

- Ensure proper alignment and secure connections to prevent leaks and ensure optimal performance.

- Operating the Cylinder:

- Start the hydraulic system and start the movement of the HROC single trunnion cylinder.

- The hydraulic control system precisely controls the cylinder extension, retraction, and positioning to achieve efficient operation.

HROC Cilindru hidraulic circular de tip trunnion unic HROC Characteristics:

- Innovative Design: The HROC single trunnion-type cylinder features a state-of-the-art design that maximizes performance, efficiency, and durability.

- Precise Control: This hydraulic cylinder provides superior motion and positioning control, allowing for accurate and efficient operation.

- High Load Capacity: HROC single trunnion-type cylinders are designed to handle heavy loads and withstand demanding industrial applications.

- Versatile Applications: The hydraulic cylinder has a universal design, which is suitable for manufacturing, construction, material handling, and other industries.

- Reliability and Durability: HROC single trunnion-type cylinders withstand harsh operating conditions, providing long-lasting performance and minimizing downtime.

- Smooth Operation: The cylinder ensures smooth and reliable operation and minimizes vibration and noise during hydraulic movement.

How Hard Is It To Rebuild A Hydraulic Cylinder?

Rebuilding a hydraulic cylinder can be a complex task that requires mechanical knowledge, experience, and the right tools. The difficulty level involved in the process can vary depending on the specific design and condition of the cylinder. Here are some factors to consider:

- Expertise and Experience:

Rebuilding a hydraulic cylinder requires a good understanding of its components, functionality, and assembly. The process may be more manageable if you have experience working with hydraulic systems or have previously rebuilt hydraulic cylinders. However, seeking professional assistance or guidance is recommended if you’re new to hydraulic systems. - Cylinder Design:

The complexity of rebuilding a hydraulic cylinder can depend on its design. Some cylinders have more straightforward construction with fewer internal components, making them relatively easier to rebuild. However, more advanced techniques, such as those with multiple stages or integrated features, can be more intricate and challenging to disassemble, reseal, and reassemble correctly. - Condition of the Cylinder:

The overall condition of the hydraulic cylinder also affects the rebuilding process. If the cylinder has severe damage, extensive wear, or corrosion, it may require additional repairs or part replacements, which can add complexity to the rebuild. Assessing the cylinder’s condition beforehand will help determine the level of work needed. - Tools and Equipment:

Rebuilding a hydraulic cylinder often requires specialized tools and equipment. These include hydraulic presses, seal installation tools, snap ring pliers, and torque wrenches. Having the necessary tools and knowing how to use them properly is crucial for a successful rebuild. - Seal Replacement and Assembly:

One of the critical steps in rebuilding a hydraulic cylinder is replacing the seals. Ensuring the correct selection and installation of seals is essential for proper functioning and preventing leaks. It requires precision and attention to detail. Additionally, reassembling the cylinder components in the correct order and alignment is crucial for its optimal performance. - Testing and Verification:

After rebuilding the hydraulic cylinder, it’s essential to perform thorough testing to ensure it operates as intended. This can involve pressure testing, checking for leaks, and verifying the cylinder’s range of motion and performance. Proper testing helps identify issues and ensures the cylinder is safe and reliable.

Capabilitatea și capacitatea fabricii:

(1) Montaj

Avem o platformă de asamblare independentă de cercetare și dezvoltare de primă clasă. Atelierul de producție a cilindrilor hidraulici are patru linii de asamblare semiautomate pentru cilindri de ridicare și o linie de asamblare automată a cilindrilor de înclinare, cu o capacitate de producție anuală proiectată de 1 milion de bucăți. Atelierul de cilindri speciali este echipat cu diverse specificații ale unui sistem de asamblare semi-automat de curățare, cu o capacitate de producție anuală proiectată de 200.000 și dotat cu echipamente celebre de prelucrare CNC, un centru de prelucrare, un echipament special de prelucrare a cilindrilor de înaltă precizie, o mașină de sudură robotizată, o mașină de curățare automată, o mașină de asamblare automată a cilindrilor și o linie de producție automată de vopsire. Echipamente critice existente de peste 300 de seturi (seturi). Alocarea optimă și utilizarea eficientă a resurselor de echipamente asigură cerințele de precizie ale produselor și satisface nevoile de înaltă calitate ale produselor.

(2) Prelucrare

Atelierul de prelucrare este echipat cu un centru de strunjire cu șină înclinată personalizat, un centru de prelucrare, o mașină de honuire de mare viteză, un robot de sudură și alte echipamente conexe, care pot gestiona prelucrarea tuburilor cilindrice cu un diametru interior maxim de 400 mm și o lungime maximă de 6 metri.

(3) Sudură

(4) Vopsire și acoperire

Cu linii automate de acoperire cu vopsea pe bază de apă cu cilindru de dimensiuni mici și medii, pentru a realiza încărcarea și descărcarea automată a robotului și pulverizarea automată, capacitatea de proiectare de 4000 de bucăți pe schimb;

Avem, de asemenea, o linie de producție semi-automată de vopsire pentru cilindri mari, acționată de un lanț de putere, cu o capacitate de proiectare de 60 de cutii pe schimb.

(5) Testarea

Dispunem de instalații de inspecție și bancuri de testare de primă clasă pentru a ne asigura că performanța cilindrului îndeplinește cerințele.

We are one of the best metallurgical hydraulic cylinder manufacturers. We can offer comprehensive metallurgical hydraulic cylinder stock. We also provide corresponding cutii de viteze agricole. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and să coopereze cu noi!

Faceți un tur al fabricii noastre VR:

Faceți un tur al fabricii noastre VR cu următoarele

Cilindru hidraulic Aplicație: