Mobile Crane Steering Cylinder

Fiind unul dintre producătorii, furnizorii și exportatorii de cilindri hidraulici, oferim cilindri hidraulici și multe alte produse.

Vă rugăm să luați legătura cu noi pentru detalii.

Mail:sales@hydraulic-cylinders.net

Producător, furnizor, exportator de cilindri hidraulici.

Mobile Crane Steering Cylinder

The mobile crane steering cylinder is a vital component that plays a crucial role in ensuring precise steering control and maneuverability of mobile cranes during lifting operations. Designed specifically for mobile cranes, this hydraulic cylinder enables operators to navigate the crane accurately, enhancing safety and efficiency on construction sites and industrial settings.

The mobile crane steering cylinder is an essential component that ensures precise steering control and maneuverability in mobile crane lifting operations. With its robust construction, hydraulic power, and optimal steering performance, this hydraulic cylinder enables operators to navigate mobile cranes accurately and confidently. Following proper usage methods and adhering to recommended maintenance practices, operators can maximize the lifespan and reliability of the mobile crane steering cylinder, leading to safe and efficient lifting operations. Choose this indispensable hydraulic component to achieve precision steering and enhance maneuverability in your mobile crane operations.

Mobile Crane Steering Cylinder Key Characteristics:

- Robust Construction and Durability:

- The mobile crane steering cylinder is constructed with high-quality materials, providing exceptional strength and durability.

- It is designed to withstand heavy loads, shocks, and harsh environmental conditions, ensuring reliable performance even in demanding work environments.

- Hydraulic Control and Precision:

- This cylinder operates through a hydraulic control system, allowing for precise steering control of the mobile crane.

- The hydraulic control ensures smooth and responsive steering, enabling operators to maneuver the crane accurately and precisely.

- Optimal Steering Performance:

- The mobile crane steering cylinder is engineered to deliver optimal steering performance, allowing operators to navigate the crane effortlessly.

- It provides the necessary force to turn the wheels, ensuring smooth and controlled steering movements.

- Enhanced Safety and Maneuverability:

- Precise steering control is crucial for ensuring the safety and maneuverability of mobile cranes.

- The mobile crane steering cylinder enables operators to control the crane’s movement, minimizing the risk of accidents and ensuring safe and efficient operation.

Mobile Crane Steering Cylinder Parameter:

| Product Name | Mobile Crane Steering Cylinder |

| Features: | Steering system for crane chassis tires |

| Bore diameter: | 63mm~200mm |

| Rod diameter: | 36mm~140mm Stroke≤1000mm |

| Pressure: | Maximum 35MPa |

| Telescopic Cylinder Applications: | Mobile Crane |

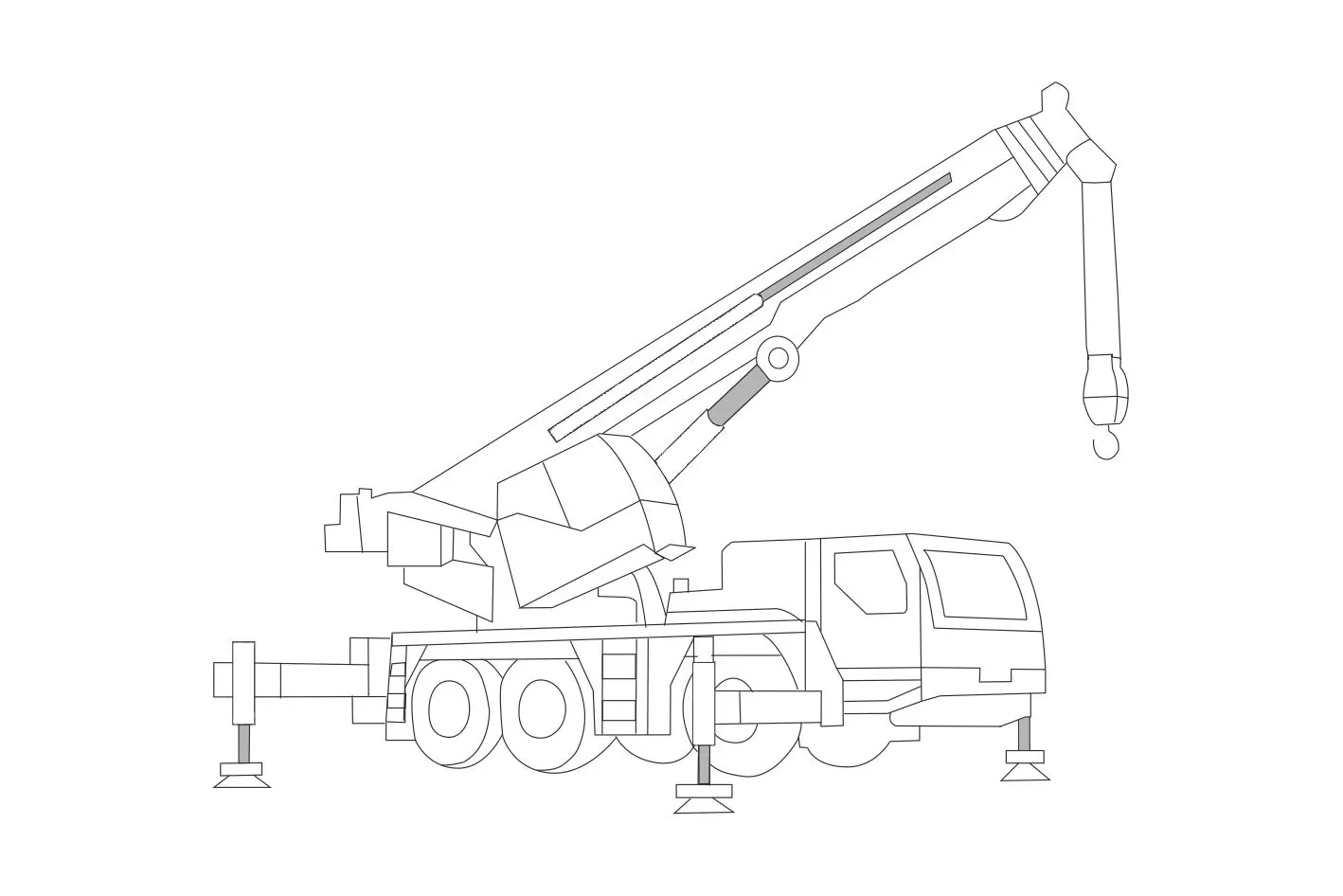

Mobile Crane Identification Diagram:

Usage Method Of Mobile Crane Steering Cylinder:

- Familiarize with Controls and Safety Guidelines:

- Before operating the mobile crane, operators should familiarize themselves with the crane’s steering controls and safety guidelines.

- Ensure all safety procedures and precautions are followed to ensure safe lifting operations.

- Steering Control:

- Use the steering wheel or joystick to control the steering of the mobile crane.

- The Mobile Crane Steering Cylinder will translate the input from the controls into the necessary force to turn the wheels.

- Smooth Steering Movements:

- Maintain a steady and controlled steering input to achieve smooth and precise steering movements.

- Avoid abrupt or jerky steering actions, which can affect stability and compromise safety.

- Adapt to Terrain and Load Conditions:

- Adjust the steering input based on the terrain and load conditions.

- Be mindful of the crane’s center of gravity and make necessary steering adjustments to ensure stability and balance.

What Is Charge Pressure In Hydraulic System?

In a hydraulic system, the charge pressure refers to the pressure level maintained in the system’s accumulator or charge pump. It is typically lower than the operating pressure used for powering actuators or performing work. The charge pressure serves several important purposes in a hydraulic system:

- Energy Storage: In systems that utilize an accumulator, the charge pressure is responsible for storing hydraulic energy. When the system’s pump exceeds the required flow rate, the excess fluid is directed to the accumulator, which compresses a gas (such as nitrogen) or uses a spring mechanism to store energy in the pressurized fluid. This stored energy can be released later to provide instantaneous power during peak demand or to supplement the pump’s output.

- System Readiness: The charge pressure ensures the system is ready for immediate operation. The hydraulic system is primed and prepared to respond quickly to the operator’s commands or sudden load changes by maintaining a consistent pressure level. This reduces response time and enables rapid actuator movement, enhancing the system’s overall performance.

- Leakage Compensation: Hydraulic systems may experience minor internal or external leaks over time. The charge pressure compensates for these leaks by replenishing the lost fluid volume. This ensures that an adequate supply of hydraulic fluid is available for proper system operation, preventing any loss of functionality or reduction in performance due to leaks.

- System Stability: The charge pressure contributes to system stability by minimizing the potential for cavitation and maintaining a positive pressure environment. Cavitation occurs when the pressure drops below the vapor pressure of the hydraulic fluid, causing the formation and subsequent collapse of vapor bubbles. This can lead to damage to system components and a decrease in overall performance. Maintaining a sufficient charge pressure reduces the risk of cavitation, ensuring stable and reliable operation.

Capabilitatea și capacitatea fabricii:

(1) Montaj

Avem o platformă de asamblare independentă de cercetare și dezvoltare de primă clasă. Atelierul de producție a cilindrilor hidraulici are patru linii de asamblare semiautomate pentru cilindri de ridicare și o linie de asamblare automată a cilindrilor de înclinare, cu o capacitate de producție anuală proiectată de 1 milion de bucăți. Atelierul de cilindri speciali este echipat cu diverse specificații ale unui sistem de asamblare semi-automat de curățare, cu o capacitate de producție anuală proiectată de 200.000 și dotat cu echipamente celebre de prelucrare CNC, un centru de prelucrare, un echipament special de prelucrare a cilindrilor de înaltă precizie, o mașină de sudură robotizată, o mașină de curățare automată, o mașină de asamblare automată a cilindrilor și o linie de producție automată de vopsire. Echipamente critice existente de peste 300 de seturi (seturi). Alocarea optimă și utilizarea eficientă a resurselor de echipamente asigură cerințele de precizie ale produselor și satisface nevoile de înaltă calitate ale produselor.

(2) Prelucrare

Atelierul de prelucrare este echipat cu un centru de strunjire cu șină înclinată personalizat, un centru de prelucrare, o mașină de honuire de mare viteză, un robot de sudură și alte echipamente conexe, care pot gestiona prelucrarea tuburilor cilindrice cu un diametru interior maxim de 400 mm și o lungime maximă de 6 metri.

(3) Sudură

(4) Vopsire și acoperire

Cu linii automate de acoperire cu vopsea pe bază de apă cu cilindru de dimensiuni mici și medii, pentru a realiza încărcarea și descărcarea automată a robotului și pulverizarea automată, capacitatea de proiectare de 4000 de bucăți pe schimb;

Avem, de asemenea, o linie de producție semi-automată de vopsire pentru cilindri mari, acționată de un lanț de putere, cu o capacitate de proiectare de 60 de cutii pe schimb.

(5) Testarea

Dispunem de instalații de inspecție și bancuri de testare de primă clasă pentru a ne asigura că performanța cilindrului îndeplinește cerințele.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding cutii de viteze agricole. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and să coopereze cu noi!

Faceți un tur al fabricii noastre VR:

Faceți un tur al fabricii noastre VR cu următoarele

Cilindru hidraulic Aplicație: