Replacement Of AL224202 Hydraulic Cylinder

Fiind unul dintre producătorii, furnizorii și exportatorii de cilindri hidraulici, oferim cilindri hidraulici și multe alte produse.

Vă rugăm să luați legătura cu noi pentru detalii.

Mail:sales@hydraulic-cylinders.net

Producător, furnizor, exportator de cilindri hidraulici.

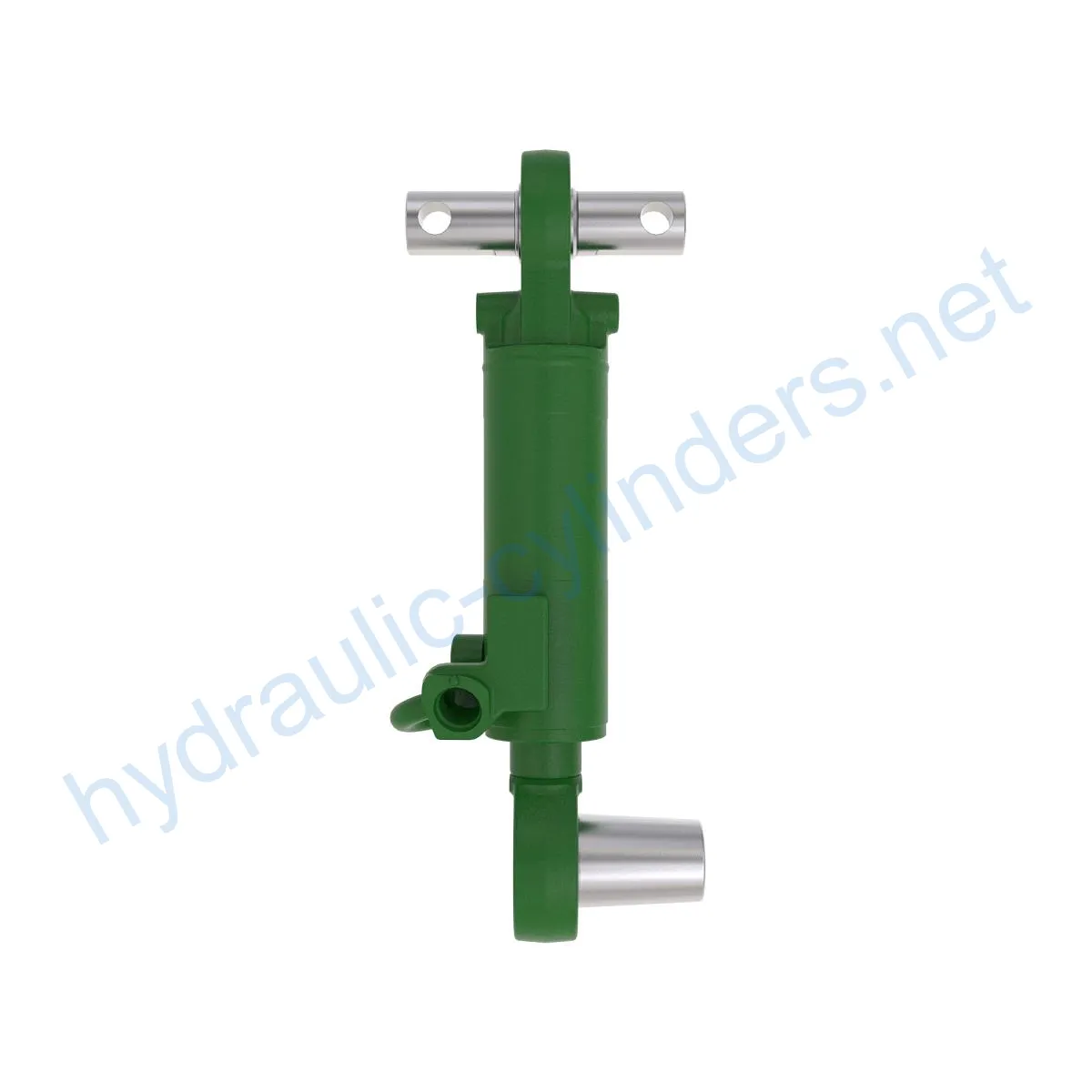

Replacement Of AL224202 Hydraulic Cylinder

The Replacement Of AL224202 Hydraulic Cylinder is a crucial component designed to improve the performance and functionality of various machinery. This hydraulic cylinder is specifically designed to replace the AL224202 model, ensuring seamless operation and compatibility.

Specifications and Models

The Replacement Of AL224202 Hydraulic Cylinder has the following specifications:

- Weight: 37.36 lb

- Height: 9.5 in

- Width: 11.6 in

- Length: 21 in

It is compatible with the following machine models:

- 6R 230

- 6R 250

- 6R 2304

- 6230R

- 6250R

Key Features

The Replacement Of AL224202 Hydraulic Cylinder offers several notable features:

- Enhanced Equipment Performance: Replacing damaged or worn hydraulic cylinders can restore the normal operational capabilities of machinery, ensuring optimal performance in various applications.

- Improved Safety: Regularly replacing hydraulic cylinders reduces the safety hazards associated with cylinder failures, ensuring the well-being of operators and equipment.

- Overload Protection: The design of new cylinders often incorporates improved overload protection mechanisms, enhancing safety during operation.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it convenient to obtain replacement parts in the market.

Our company specializes in the production of this product, offering perfect replacements for these hydraulic cylinders.

Applications

The Replacement Of AL224202 Hydraulic Cylinder finds application in various scenarios, including:

- Excavators: Hydraulic cylinders in excavator arms or buckets may require replacement due to prolonged use or overloading, ensuring the restoration of normal operations.

- Cranes: Hydraulic cylinders in crane boom arms are prone to wear and tear due to frequent lifting and lowering, necessitating regular replacement for safety purposes.

- Tractors: Hydraulic cylinders in front-end loader attachments for tractors may experience leaks or performance decline during continuous lifting and tilting operations, requiring replacement.

- Harvesters: Hydraulic cylinders in harvesting equipment endure high pressure during operation and can be subject to fatigue damage, necessitating timely replacement to maintain work efficiency.

- Automated Production Lines: Hydraulic cylinders are used to control robotic arms and other automated equipment. Cylinder failures can adversely impact production efficiency and should be replaced immediately.

These are just a few examples of the Replacement Of AL224202 Hydraulic Cylinder’s applications. Each application plays a crucial role in specific industries, ensuring smooth and efficient operations.

Maintenance and Care

To ensure the longevity and optimal performance of the Replacement Of AL224202 Hydraulic Cylinder, the following maintenance tasks are recommended:

- Regular Inspections: Periodically inspecting the hydraulic cylinder allows for the early detection of any potential issues, preventing major problems.

- Proper Lubrication: Adequate lubrication of the cylinder’s moving parts is essential for smooth operation. Regularly applying the recommended hydraulic oil enhances performance and reduces friction.

- Seal Replacement and Calibration Checks: It is important to replace worn-out seals and conduct calibration checks to maintain the cylinder’s integrity and functionality.

During installation, it is crucial to provide proper alignment guidance and recommend the use of suitable mounting brackets for securing the cylinder. We also offer inspection, repair, and replacement services to extend the lifespan of the hydraulic cylinder.

Safety Considerations and Environmental Factors

When using the Replacement Of AL224202 Hydraulic Cylinder, it is vital to implement appropriate safety measures. Adhering to safety protocols and guidelines ensures the well-being of operators and prevents accidents or injuries. Additionally, considering environmental factors during the operation of hydraulic cylinders can contribute to sustainable and eco-friendly practices.

Troubleshooting and Common Issues

Despite its durability and reliability, the Replacement Of AL224202 Hydraulic Cylinder may encounter certain issues. Here are some common problems and their solutions:

- Leakage: If the hydraulic cylinder is experiencing leakage, it is recommended to inspect and replace the seals or O-rings, ensuring a proper seal to prevent further leakage.

- Poor Performance: In case of reduced performance, check for any internal damage or contamination. Cleaning or replacing the affected parts can effectively resolve this issue.

- Noise or Vibrations: Unusual noise or vibrations may indicate misalignment or damaged components. Adjusting the alignment or replacing the damaged parts can rectify this problem.

It is essential to diagnose and address these issues promptly to avoid any disruptions in operation and maintain the efficiency of the hydraulic cylinder.

Preventive Measures and Maintenance Tips

To minimize potential problems and ensure prolonged performance, the following preventive measures are recommended:

- Regularly inspect the hydraulic cylinder for any signs of wear, damage, or leaks.

- Follow the manufacturer’s guidelines for lubrication and use the appropriate hydraulic oil.

- Ensure proper alignment and installation of the cylinder to prevent premature wear or damage.

- Provide adequate training to operators on the proper use and maintenance of the hydraulic cylinder.

By implementing these preventive measures, operators can maximize the lifespan and functionality of the Replacement Of AL224202 Hydraulic Cylinder.

Design Considerations and Selection Criteria

When designing and selecting the Replacement Of AL224202 Hydraulic Cylinder, several factors should be considered:

- Load-Bearing Capacity: The hydraulic cylinder should be capable of handling the specific load requirements of the machinery.

- Sealing and Durability: Utilizing various sealing components, such as piston seals and rod seals made of wear-resistant materials like polyurethane or nitrile rubber, ensures a reliable and long-lasting seal. Additionally, finely treated cylinder bodies and threaded ends enhance wear resistance.

- Safety: The design should incorporate safety features to prevent accidents and ensure the well-being of operators.

- Maintainability: Easy access to components and the availability of replacement parts contribute to efficient maintenance and repairs.

These considerations guarantee optimal performance and reliability when selecting the Replacement Of AL224202 Hydraulic Cylinder for specific applications.

Sealing and Lubrication

To ensure proper sealing and lubrication, the Replacement Of AL224202 Hydraulic Cylinder utilizes various sealing components, including piston seals and rod seals. These seals are made of wear-resistant materials such as polyurethane and nitrile rubber. The cylinder body and threaded ends undergo fine treatment

Faceți un tur al fabricii noastre VR:

Faceți un tur al fabricii noastre VR cu următoarele

Cilindru hidraulic Aplicație: