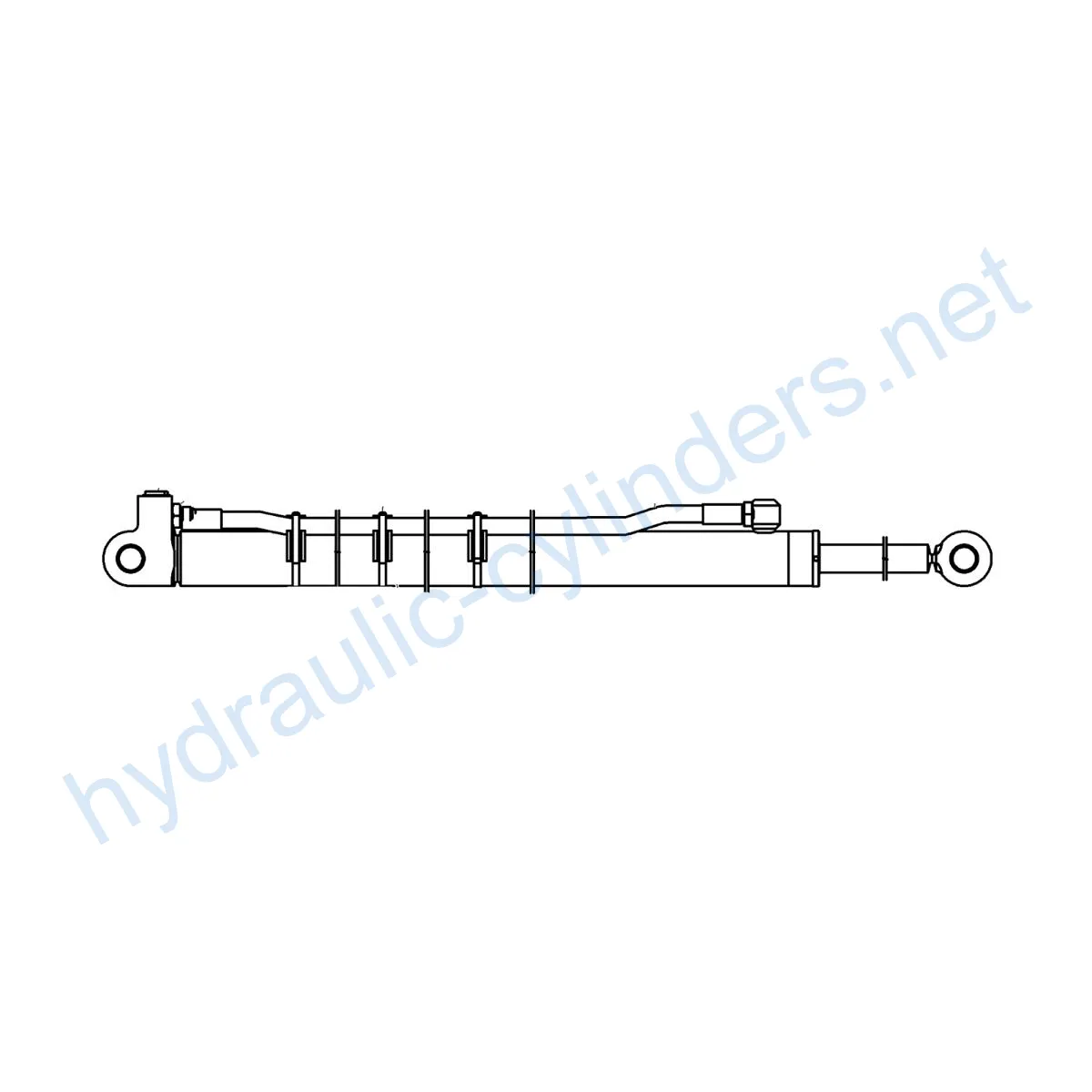

Replacement Of F074135 Hydraulic Cylinder Rod

Ako jeden z výrobcov, dodávateľov a vývozcov mechanických výrobkov ponúkame hydraulické valce a mnoho ďalších výrobkov.

Kontaktujte nás, ak chcete získať podrobné informácie.

Pošta:sales@hydraulic-cylinders.net

Výrobca dodávateľ vývozca hydraulických valcov.

Introduction

The Replacement Of F074135 Hydraulic Cylinder Rod is a hydraulic cylinder used for various machines such as 1010D, 1010E, 1110D, 1110E, 1110G, 1210E, 1210G, 1510E, 1510G, CF5, CF7. It weighs 35lb, its height is 64.5in and its length is 1.8in. A hydraulic cylinder is a mechanical actuator used to provide unidirectional force through a unidirectional stroke.

Specifications and Models

The Replacement Of F074135 Hydraulic Cylinder Rod has a weight of 35lb, a height of 64.5in and a length of 1.8in. It can be used for 1010D, 1010E, 1110D, 1110E, 1110G, 1210E, 1210G, 1510E, 1510G, CF5, and CF7 models.

Features

- Improved equipment performance: Replacing damaged or worn hydraulic cylinders can restore the equipment’s normal operating capabilities, ensuring its performance in various applications.

- Enhanced safety: Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload protection: Newly designed cylinders usually consider better overload protection mechanisms, enhancing safety.

- Fast installation: Modern hydraulic cylinders are designed to be easy to install and replace, reducing downtime.

- Standardized components: Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts on the market.

Applications

The Replacement Of F074135 Hydraulic Cylinder Rod can be used in various applications such as:

- Excavators: Replacing damaged or worn hydraulic cylinders on the arm or bucket of an excavator can restore its normal operation.

- Cranes: Regularly replacing the crane’s boom hydraulic cylinder ensures safety during frequent lifting and lowering operations.

- Tractors: The front loader hydraulic cylinder of a tractor can be replaced to prevent leakage or performance decline during continuous lifting and tilting operations.

- Harvesters: Regularly replacing hydraulic cylinders in harvesters can maintain work efficiency and productivity.

- Automation production lines: Hydraulic cylinders are used to control robotic arms and other automated equipment. Immediate replacement is necessary when a cylinder fails to avoid production downtime.

- Die-casting machines: Regularly replacing hydraulic cylinders can ensure product quality in high-pressure and high-temperature environments.

- Mining equipment: Hydraulic cylinders are used to lift and move heavy objects in mining equipment. Regular inspection and replacement are necessary to avoid equipment failure.

- Bulldozers: Replacing worn hydraulic cylinders on the bulldozer’s blade can prevent a decrease in its pushing ability.

Maintenance Tasks

Common maintenance tasks for hydraulic cylinders include:

- Regular inspections

- Proper lubrication

- Seal replacement

- Calibration checks

It is important to provide proper installation guidance during the installation process, use appropriate installation brackets to fix the cylinder, and follow recommended inspection, repair, and replacement procedures to ensure the longevity of the hydraulic cylinder.

Safety Considerations and Environmental Factors

When using hydraulic cylinders, it is important to consider safety measures such as wearing protective gear and ensuring proper installation. Environmental factors such as temperature and pressure can also affect the performance of hydraulic cylinders, so regular inspections and maintenance are crucial for their safe and efficient use.

Troubleshooting and Common Issues

Common issues with hydraulic cylinders include leakage, slow operation, and insufficient force. To troubleshoot these issues, inspect the cylinder for damage or wear, check the hydraulic fluid levels, and ensure proper installation and alignment. Preventative measures such as regular inspections and maintenance can also help avoid potential problems.

Design Considerations and Selection Criteria

When selecting a hydraulic cylinder, it is important to consider factors such as load-bearing capacity, sealing, durability, safety, and serviceability. The use of various seals such as piston seals and rod seals made of wear-resistant materials such as polyurethane and nitrile rubber and the use of finely processed cylinder bodies and threaded ends can improve durability. Regular lubrication is also necessary to improve longevity and efficiency.

Our Company

We are a manufacturer of replacement hydraulic cylinders with a wide range of products. We are one of the leading manufacturers and wholesale distributors of hydraulic cylinders worldwide. We provide professional services, international certifications, customized services, advanced production equipment, and excellent after-sales service.

Author: lyl

Prezrite si našu továreň na VR:

Vydajte sa na prehliadku našej továrne na VR

Použitie hydraulického valca: