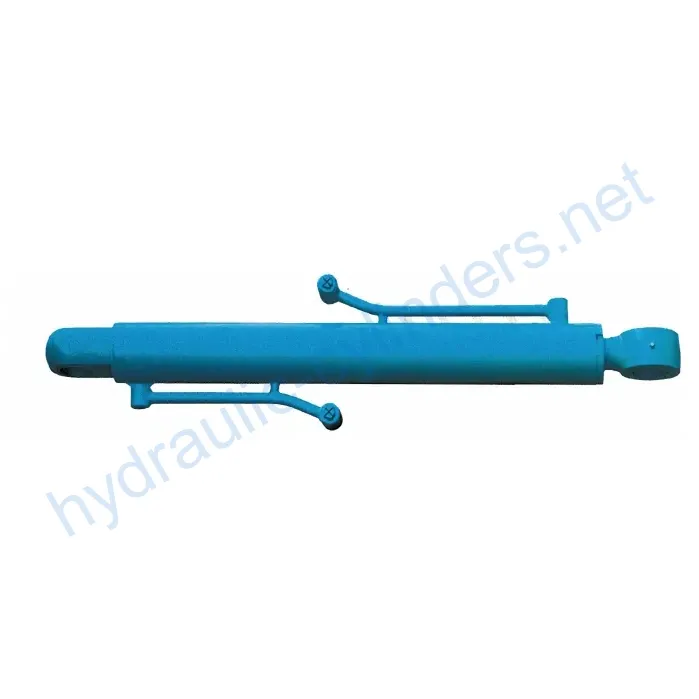

Bucket Cylinder For Kobelco Small Excavator SK100-3-5-6

Kot eden od proizvajalcev, dobaviteljev in izvoznikov hidravličnih cilindrov ponujamo hidravlične cilindre in številne druge izdelke.

Za podrobnosti se obrnite na nas.

Pošta:sales@hydraulic-cylinders.net

Proizvajalec, dobavitelj in izvoznik hidravličnih cilindrov.

Bucket Cylinder For Kobelco Small Excavator SK100-3-5-6

Introduction

The Bucket Cylinder for Kobelco Small Excavator SK100-3-5-6 is a specialized hydraulic cylinder designed primarily to control the movement of the bucket in heavy machinery, such as excavators, backhoe excavators, and front loaders. Its primary function is to allow the bucket to lift, lower, and tilt, making it easier to handle a variety of materials in different tasks. In the hydraulic system, the bucket cylinder uses the pressure change of the hydraulic oil to precisely control the bucket, enabling the operator to handle heavy loads efficiently and adapt to complex working environments and diverse operational needs.

Features

-

High Strength and Durability

Bucket cylinders are typically made from high-strength steel or aluminum, capable of withstanding high pressure and heavy loads, adapting to harsh working environments. The design considers wear resistance and corrosion resistance, extending the service life.

-

Efficient Hydraulic Operation

Bucket cylinders utilize the pressure of hydraulic oil to achieve smooth telescopic action, able to respond quickly to control commands, providing powerful pushing and pulling force, suitable for handling heavy loads and complex tasks.

-

Diverse Types

Bucket cylinders can be single-acting (hydraulics only used in one direction) or double-acting (hydraulics used in both directions) cylinders, allowing for different operational requirements. Some models are telescopic, allowing for greater extension without increasing external dimensions, suitable for limited space applications.

-

Product Availability

Our company produces bucket cylinders that can perfectly replace these hydraulic cylinders.

-

Wide Range of Applications

The bucket cylinder is widely used in various heavy machinery such as:

- Construction equipment: excavators, backhoe excavators, loaders

- Agricultural machinery: front-end loaders, excavators

Bucket cylinders facilitate digging, loading, and transporting soil, hay, and other materials.

Design Considerations and Selection Criteria

-

Bearing Capacity

The bucket cylinder must be able to withstand heavy loads and operate reliably under high pressure.

-

Sealing

The cylinder must be well-sealed to prevent hydraulic oil leakage and ensure the proper functioning of the cylinder.

-

Durability

The bucket cylinder must be durable, resistant to wear, corrosion, and damage from harsh conditions and external factors.

-

Safety

The bucket cylinder must be designed with safety considerations, including measures such as safety valves and safety devices.

-

Maintainability

The bucket cylinder must be designed with easy maintenance in mind, including easy access to internal components, easy disassembly, and easy replacement of parts.

Sealing and Lubrication

Various sealing components, such as piston seals and rod seals, are used to prevent hydraulic oil leakage. Sealing components are made from wear-resistant materials such as polyurethane and nitrile rubber. The cylinder body and threaded end surface have undergone fine processing to increase wear resistance. Regularly adding the appropriate amount of hydraulic oil is necessary to ensure the lubrication of the hydraulic cylinder.

Periodic Inspection and Preventive Maintenance Measures

It is recommended to regularly inspect and maintain the bucket cylinder to ensure its proper functioning and extend its service life. Common maintenance tasks include lubrication, sealing replacement, and calibration checks. Correct installation, lubrication, and adjustment are crucial to the proper functioning of the cylinder. Proper alignment and the use of appropriate mounting brackets are recommended during installation. Recommended inspection, repair, and replacement procedures are provided, and replacement parts and rebuild services are available to improve the longevity of the hydraulic cylinder.

Safety Considerations and Environmental Factors

When using the bucket cylinder, it is vital to follow safety measures to prevent personal injury or damage to equipment. It is essential to ensure that the equipment is securely installed and that the operator is trained and qualified. Adverse environmental factors such as temperature, humidity, and pollution can affect the cylinder’s performance, and appropriate measures should be taken to mitigate these factors.

Troubleshooting and Common Problems

Common problems with the bucket cylinder include oil leaks, damage to the cylinder body and piston, and insufficient operational force. Proper maintenance and inspection can help identify and prevent these issues. Troubleshooting tips and solutions are provided to help readers effectively diagnose and solve problems and prevent potential issues.

About Our Company

Our company is a hydraulic cylinder manufacturer that specializes in replacing hydraulic cylinders. We have a complete range of products and are one of the leading manufacturers and wholesalers of hydraulic cylinders in domestic and international markets. We follow the principle of excellent quality and rely on the industrial production management strategy of a fine manufacturing workshop. We continuously improve the manufacturing platform by applying technology talent, digital high-end manufacturing equipment, and professional testing systems, perfecting the product quality production route, and creating a strong creation ability. We meet customer’s diverse needs with high efficiency, high precision, and high quality.

Professionalism

Our company has a team of professionals with extensive experience and knowledge in the hydraulic cylinder industry, providing customers with professional, efficient, and reliable services.

International Certification

Our products have passed international certification, including ISO 9001 and CE certification. Our products are of high quality and comply with international standards.

Customization Services

We provide customized services to meet customers’ specific requirements, providing tailored solutions to meet their needs.

Production Equipment

We have advanced and modern production equipment, including CNC machining centers, CNC lathes, and other high-tech equipment, to ensure the production of high-quality products.

After-sales Service

We provide comprehensive after-sales services, including maintenance, repair, and replacement of parts, to ensure customer satisfaction and the proper functioning of their hydraulic cylinders.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: