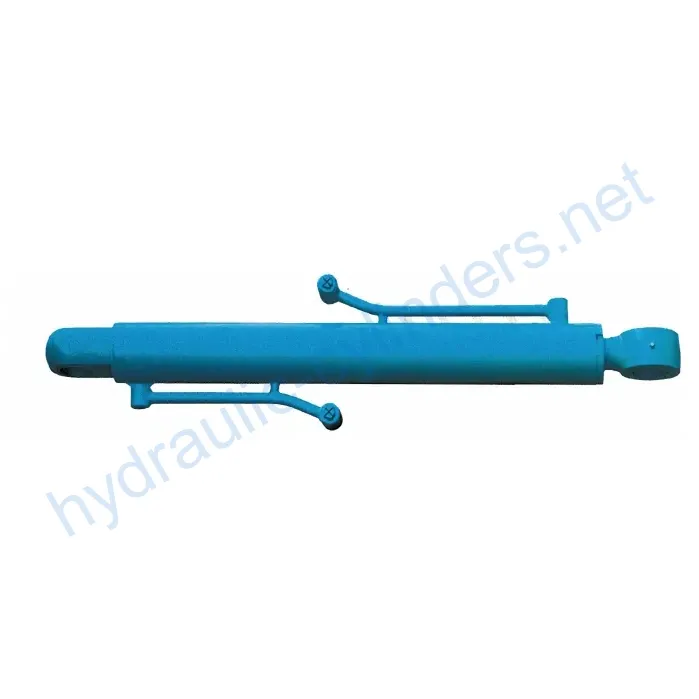

Bucket Cylinder For Sinomach ZG3225C-9C

Kot eden od proizvajalcev, dobaviteljev in izvoznikov hidravličnih cilindrov ponujamo hidravlične cilindre in številne druge izdelke.

Za podrobnosti se obrnite na nas.

Pošta:sales@hydraulic-cylinders.net

Proizvajalec, dobavitelj in izvoznik hidravličnih cilindrov.

Bucket Cylinder For Sinomach ZG3225C-9C

Introduction

The bucket cylinder for Sinomach ZG3225C-9C is a specially designed hydraulic cylinder used to control the movement of the bucket in heavy machinery such as excavators, backhoe loaders, and front-end loaders. Its main function is to enable the bucket to lift, lower, and tilt, making it convenient for various material handling tasks. In the hydraulic system, the bucket cylinder achieves precise control of the bucket’s movement through changes in hydraulic oil pressure, enabling operators to efficiently handle heavy loads, adapt to complex working environments, and diverse job requirements.

Features

- High strength and durability: Typically made of high-strength steel or aluminum, it can withstand high pressure and heavy loads, adapts to harsh working environments, and is designed with consideration for wear resistance and corrosion resistance to extend service life.

- Efficient hydraulic operation: Uses hydraulic oil pressure to achieve smooth extension and retraction, able to respond quickly to control commands, provide strong pushing and pulling force, suitable for handling heavy loads and complex job tasks.

- Diverse types: Can choose single-acting (hydraulic is used in only one direction) or double-acting (hydraulic is used in both directions) cylinders as needed to meet different operational requirements. Some models are telescopic, allowing for greater extension without increasing external size, suitable for applications with limited space.

- Easy to replace: Our product can perfectly replace these hydraulic cylinders.

Applications

The bucket cylinder for Sinomach ZG3225C-9C is widely used in various heavy machinery. Some of its applications include:

- Construction equipment: In excavators, they are essential for digging, loading, and moving soil or debris. In backhoe loaders, bucket cylinders aid in both digging and lifting.

- Agricultural machinery: Used in front-end loaders for scooping, lifting, and transporting soil, hay, and other materials.

- Excavators: Bucket cylinders enable digging actions by allowing the bucket to penetrate the soil.

- Loaders: In front-end loaders, they aid in lifting and dumping cargo efficiently.

Design Considerations and Selection Criteria

When designing the bucket cylinder, several factors are considered, such as load-bearing capacity, sealing, durability, safety, and maintainability.

Load-Bearing Capacity

The bucket cylinder must be able to withstand the maximum load and pressure it may experience during operation. It is typically made of high-strength steel or aluminum, which ensures its durability and ability to withstand heavy loads and high pressures.

Sealing

The bucket cylinder uses various sealing components such as piston seals, rod seals, etc., made of wear-resistant materials such as polyurethane and nitrile rubber. The cylinder body and threaded end surface are finely processed to improve wear resistance, which can effectively prevent oil leakage and ensure stable operation of the cylinder.

Durability

The bucket cylinder is designed with consideration for wear resistance and corrosion resistance to extend its service life, which ensures that it can withstand harsh working environments and frequent use.

Safety

When designing the bucket cylinder, safety is always a top priority. It should be engineered to prevent accidents and ensure safe operation at all times. Proper maintenance and inspection procedures should be followed to ensure safe and reliable operation.

Maintainability

The bucket cylinder is designed to be easily repaired or maintained in the field. It is important to follow proper maintenance and inspection procedures to ensure safe and reliable operation.

Sealing and Lubrication

The bucket cylinder uses various sealing components such as piston seals, rod seals, etc., made of wear-resistant materials such as polyurethane and nitrile rubber. The cylinder body and threaded end surface are finely processed to improve wear resistance, which can effectively prevent oil leakage. It needs to be regularly lubricated with a suitable amount of hydraulic oil to ensure smooth operation.

Maintenance and Repair

Regular inspection and preventive maintenance are essential for ensuring the proper operation and long service life of the bucket cylinder. Common maintenance tasks include lubrication, seal replacement, and calibration checks.

Lubrication

Proper lubrication is vital for ensuring smooth operation and preventing wear and tear. Use the recommended lubricant and follow the manufacturer’s instructions for how much and how often to lubricate.

Seal Replacement

If you notice oil leakage, this may indicate that a seal has cracked or worn out and needs to be replaced. Replacing a seal requires removing the cylinder and disassembling it, so it is important to follow the manufacturer’s instructions and use the correct tools.

Calibration Checks

Periodically checking the calibration of the cylinder can help ensure that it is operating correctly. If you notice any issues, such as slow response or reduced power output, it may be time to have the cylinder recalibrated or repaired.

Safety Considerations and Environmental Factors

When using the bucket cylinder, it is important to follow proper safety procedures, such as wearing protective gear, avoiding overloading, and ensuring that the machinery is properly maintained. Environmental factors, such as weather and terrain, should also be taken into consideration.

Troubleshooting and Common Problems

If you encounter any problems with the bucket cylinder, such as oil leakage, slow response, or reduced power output, it may be time to have the cylinder inspected and repaired. Common problems may be caused by worn-out seals, lack of lubrication, or calibration issues.

About Our Company

We are a manufacturer of replacement hydraulic cylinders. Our product range is complete and we have become one of the leading manufacturers and wholesale distributors of hydraulic cylinders in domestic and international markets. We adhere to the principle of excellent quality and rely on a refined manufacturing workshop, industrial production management strategy, and professional testing system to continuously improve the manufacturing platform and perfect the production quality of our products. We have strong creative capabilities, and with high efficiency, high precision, and high quality principles, we can meet the diverse needs of our customers.

Professionalism

Our company has a team of experienced professionals who are well-versed in the latest technologies and manufacturing processes. We are committed to providing high-quality products and services that meet or exceed customer expectations.

International Certification

Our products are certified and meet international standards such as ISO9001, CE, etc.

Customization

We offer customized solutions to meet the specific needs of our customers.

Production Equipment

We have advanced production equipment, such as CNC machining centers, milling machines, and testing equipment, to ensure that our products are of high quality and meet the needs of our customers.

After-Sales Service

We provide excellent after-sales service, including technical support, maintenance, and repair services, to ensure that our customers are satisfied with our products and services.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: