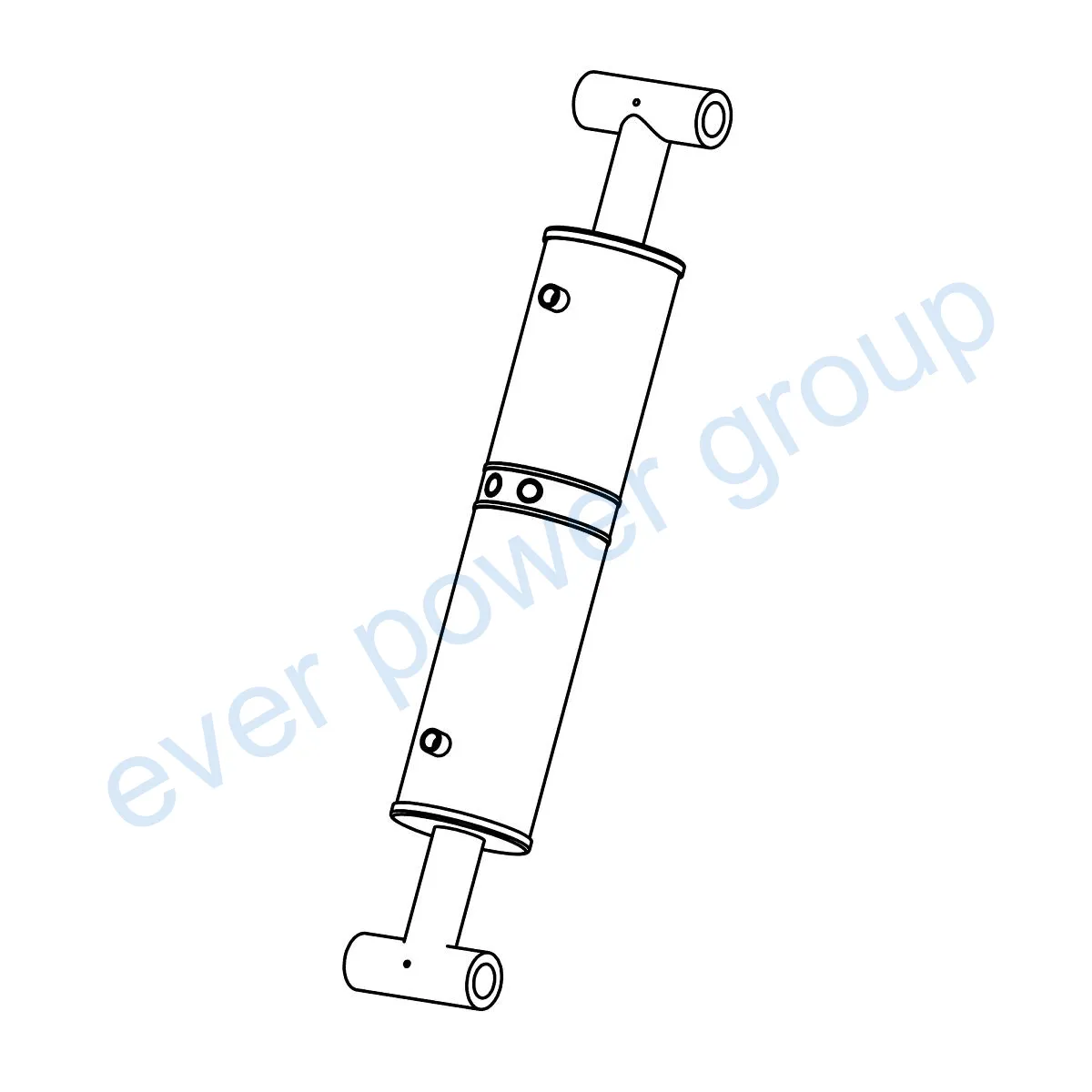

Replacement Of AKK19362 Hydraulic Cylinder

Kot eden od proizvajalcev, dobaviteljev in izvoznikov hidravličnih cilindrov ponujamo hidravlične cilindre in številne druge izdelke.

Za podrobnosti se obrnite na nas.

Pošta:sales@hydraulic-cylinders.net

Proizvajalec, dobavitelj in izvoznik hidravličnih cilindrov.

Replacement Of AKK19362 Hydraulic Cylinder

The Replacement Of AKK19362 Hydraulic Cylinder is a type of hydraulic cylinder that can be used for various applications such as construction equipment, manufacturing, transportation, and aviation. It is designed to provide stability and secure heavy loads in place.

Specifications and Models

The Replacement Of AKK19362 Hydraulic Cylinder weighs 169.76 lb, has a height of 7.5 in, and a length of 33.5 in. It is compatible with the following models: DB37, DB41, DB44, DB55, DB60, and DB62.

Features

The Replacement Of AKK19362 Hydraulic Cylinder has several features that make it stand out from other hydraulic cylinders. Some of these features include:

- High load-bearing capacity

- Excellent sealing performance

- Durable and long-lasting

- Easy maintenance and repair

- Compatible with various applications

Applications

The Replacement Of AKK19362 Hydraulic Cylinder can be used in various applications such as:

Construction Equipment

It is commonly used in cranes, hoists, and elevators where heavy loads need to be securely fastened.

Manufacturing

It is used in press machines where materials are shaped under high pressure and need to be held in place during the machining process.

Transportation

It is used in stabilizers and jacks of vehicles to ensure safety during maintenance or transportation.

Aviation

It is used in the landing gear system of aircraft to secure the landing gear in the appropriate position during takeoff and landing.

Design Considerations and Selection Standards

When designing and selecting the Replacement Of AKK19362 Hydraulic Cylinder, several factors are taken into consideration, such as its load-bearing capacity, sealing performance, durability, safety, and maintenance.

Load-bearing Capacity

The Replacement Of AKK19362 Hydraulic Cylinder is designed to withstand heavy loads and provide stability during operation.

Sealing Performance

The cylinder is equipped with various seals, such as piston seals and rod seals, made of wear-resistant materials like polyurethane and nitrile rubber, to ensure excellent sealing performance. The cylinder body and thread end surface are finely treated to improve wear resistance. Regular refilling of appropriate hydraulic oil is necessary for lubrication.

Durability

The cylinder is made of high-quality materials that are resistant to wear, corrosion, and deformation, ensuring its long-lasting performance.

Safety

The cylinder is designed with safety in mind, with features such as emergency stop valves and pressure relief valves to prevent accidents and ensure safe operation.

Maintenance

The Replacement Of AKK19362 Hydraulic Cylinder is designed for easy maintenance and repair, with components that can be easily replaced and repaired without the need for special tools.

Installation Guide

The installation of the Replacement Of AKK19362 Hydraulic Cylinder is straightforward and can be done by following these steps:

- Align the cylinder with the mounting surface.

- Secure the cylinder with suitable mounting brackets.

- Connect the hydraulic hoses and fittings to the cylinder.

- Refill the hydraulic oil to the correct level.

- Check for leaks and test the cylinder’s operation.

Maintenance and Repair

Regular maintenance and repair of the Replacement Of AKK19362 Hydraulic Cylinder are essential to ensure its optimal performance and longevity. Some common maintenance tasks include:

Regular Inspection

Periodic inspection of the cylinder for signs of wear, leaks, and damage is necessary to ensure its safe and efficient operation.

Lubrication

Proper lubrication of the cylinder’s moving parts is necessary to maintain its smooth operation and prevent premature wear and tear.

Seal Replacement

Replacement of worn-out seals is necessary to ensure the cylinder’s proper sealing performance and prevent leaks.

It is crucial to follow proper installation, lubrication, and adjustment procedures to ensure the Replacement Of AKK19362 Hydraulic Cylinder’s optimal performance and avoid potential safety hazards. In case of failure, it is recommended to seek professional assistance.

Safety Considerations and Environmental Factors

When using the Replacement Of AKK19362 Hydraulic Cylinder, it is important to follow proper safety procedures to prevent accidents and injuries. Some safety measures include:

- Use suitable personal protective equipment such as gloves and safety glasses.

- Do not exceed the cylinder’s load-bearing capacity.

- Regularly inspect the cylinder for signs of wear and damage.

- Use the cylinder only for the intended applications.

The Replacement Of AKK19362 Hydraulic Cylinder is designed with environmental factors in mind, with features such as low noise, low emissions, and energy-efficient performance.

Troubleshooting and Common Issues

The Replacement Of AKK19362 Hydraulic Cylinder may experience some common issues, such as leaks, poor sealing performance, and abnormal sounds. Some troubleshooting tips include:

Leakage

Check for damaged or worn-out seals and replace them if necessary. Make sure all fittings and connections are tightened correctly.

Poor Sealing Performance

Check for any damage or wear on the cylinder body or piston rod. Replace any damaged or worn-out components.

Abnormal Sounds

Check for any loose or damaged components and tighten or replace them if necessary.

It is essential to seek professional assistance if the issues persist or if unsure how to proceed with troubleshooting.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: