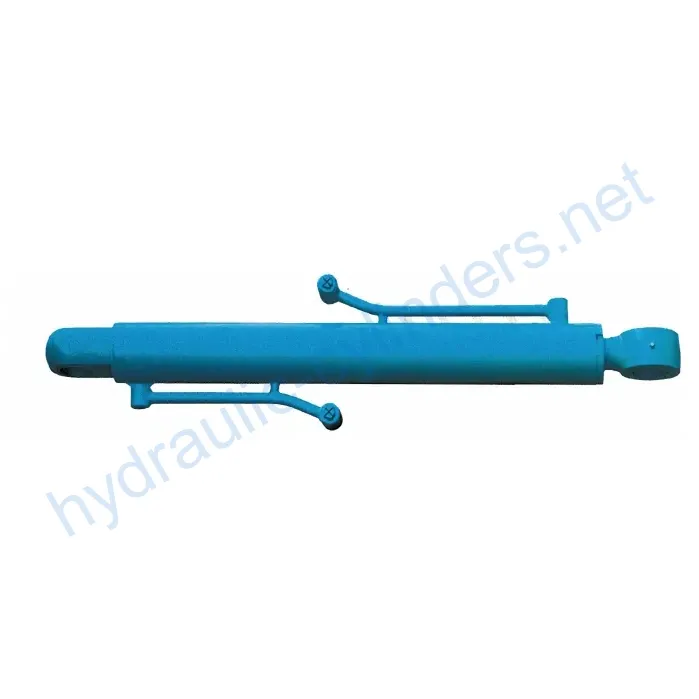

Bucket Cylinder For Sany Middle Excavator SY205C-9

Som en av tillverkarna, leverantörerna och exportörerna av mekaniska produkter erbjuder vi hydraulcylindrar och många andra produkter.

Vänligen kontakta oss för mer information.

E-post:sales@hydraulic-cylinders.net

Tillverkare, leverantör och exportör av hydraulcylindrar.

Bucket Cylinder For Sany Middle Excavator SY205C-9

Introduction

Definition

A bucket cylinder is a type of specialized hydraulic cylinder mainly used to control the movement of the bucket in heavy machinery, such as excavators, backhoe loaders, and front-end loaders. Its primary function is to enable the bucket to lift, lower, and tilt, making it easier to handle various material handling tasks. In the hydraulic system, the bucket cylinder achieves precise control of the bucket through changes in hydraulic oil pressure, allowing operators to handle heavy loads efficiently and adapt to complex working environments and diverse operational requirements.

Features

- High strength and durability: usually made from high-strength steel or aluminum, able to withstand high pressure and heavy loads, adapt to harsh working environments, and designed with wear resistance and corrosion resistance in mind to extend service life.

- Efficient hydraulic operation: utilizes hydraulic oil pressure to achieve smooth extension and retraction movements, able to quickly respond to control commands, providing powerful pushing and pulling force, suitable for handling heavy loads and complex operational tasks.

- Various types: can choose between single-acting (hydraulic used in only one direction) or double-acting (hydraulic used in both directions) cylinders according to operational needs, some models are telescopic, allowing for greater extension without increasing external dimensions, suitable for space-limited applications.

Applications

The bucket cylinder is widely used in various industrial fields, including but not limited to:

Construction Equipment

In excavators, they are critical for digging, loading, and moving soil or debris. In backhoe loaders, the bucket cylinder helps with both digging and lifting. In front-end loaders, they assist with lifting and tilting of goods effectively.

Agricultural Machinery

Used for front-end loaders, scooping, lifting, and transporting soil, hay, and other materials. In excavators, the bucket cylinder enables digging action by allowing the bucket to penetrate the soil. In front-end loaders, they help lift and dump goods effectively.

Industrial Equipment

In industrial equipment, they are used to lift and move heavy loads, such as in cranes and forklifts, as well as in manufacturing and processing equipment for handling raw materials and finished products.

Design and Selection Criteria

Load-Carrying Capacity

The key consideration in designing bucket cylinders is their load-carrying capacity. It is necessary to ensure that the cylinder is strong enough to handle the weight of the material being lifted or moved, as well as the weight of the bucket itself. The load capacity of a cylinder must be balanced with other factors such as size, weight, and cost, to provide the optimal design solution.

Sealing, Durability, Safety

The cylinder’s sealing, durability, and safety are also essential design considerations. High-quality seals and materials must be used to prevent leaks and ensure the cylinder’s longevity. The cylinder must also be designed to withstand the harsh working environment, be easy to maintain, and be safe to operate. The cylinder’s design must also incorporate safety features such as overload protection and emergency stop systems to ensure the operator’s safety.

Sealing and Lubrication

The bucket cylinder requires various sealing components, such as piston seals, rod seals, etc. These seals provide a secure and reliable seal to prevent leaks and ensure smooth operation. The seals are made of wear-resistant materials such as polyurethane and nitrile rubber, selected based on the cylinder’s specific application requirements. The cylinder must be lubricated with hydraulic oil, which should be changed regularly to maintain optimal performance.

Maintenance and Repair

Regular maintenance and inspection are essential to ensure the proper operation of the bucket cylinder. Some common maintenance tasks include lubrication, seal replacement, and calibration checks. It is crucial to install the cylinder correctly, align it properly, and use suitable mounting brackets to secure the cylinder.

Recommended Maintenance Tasks

- Regular inspection and lubrication

- Seal replacement

- Calibration checks

Safety Considerations and Environmental Factors

When using the bucket cylinder, safety measures must be taken to avoid accidents. Operators must receive appropriate training on the cylinder’s use and safety features, such as overload protection and emergency stop systems. Environmental factors, such as temperature and humidity, can also impact the cylinder’s performance and must be taken into consideration when designing, operating, and maintaining the cylinder.

Common Issues and Troubleshooting

Some common issues that can arise with bucket cylinders include leaks, damage to the cylinder body or seals, and loss of pressure. Troubleshooting these issues requires a thorough understanding of the cylinder’s design and operation principles. Regular maintenance and inspection can help prevent these issues from occurring.

About Us

We are a leading manufacturer and wholesale distributor of hydraulic cylinders in both domestic and international markets. Our products are complete in categories and comply with international certification standards. We adhere to the principle of excellent quality and rely on the industrialized production management strategies of refined manufacturing workshops. We have continuously improved our manufacturing platform and perfected our product quality production lines through the use of technical talents, digital high-end manufacturing equipment, and professional testing systems. We have strong creativity and efficiency, high precision and quality, and can meet the diverse needs of customers. We provide customized services to customers, including design, development, testing, and after-sales services, to ensure optimal product performance and longevity.

Professionalism

Our team of professionals has many years of experience in hydraulic cylinder design, manufacturing, and testing. We are committed to providing our customers with the best possible solutions to meet their unique needs.

International Certification

Our products have passed various international certification standards, such as CE, ISO, and SGS. Our commitment to quality has earned us a reputation as a trustworthy and reliable supplier of hydraulic cylinders.

Customization Services

We offer customized services to meet our customers’ specific requirements, including design, development, testing, and after-sales services. Our team of experts works closely with customers to ensure that their needs are met throughout the entire process.

Production Equipment

We have invested heavily in advanced production equipment, such as CNC machines, testing equipment, and inspection tools, to ensure that our products meet the highest quality standards.

After-Sales Service

We provide after-sales services that include technical support, replacement parts, and repair services to ensure that our customers’ hydraulic cylinders operate at peak performance for an extended period.

Author lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: