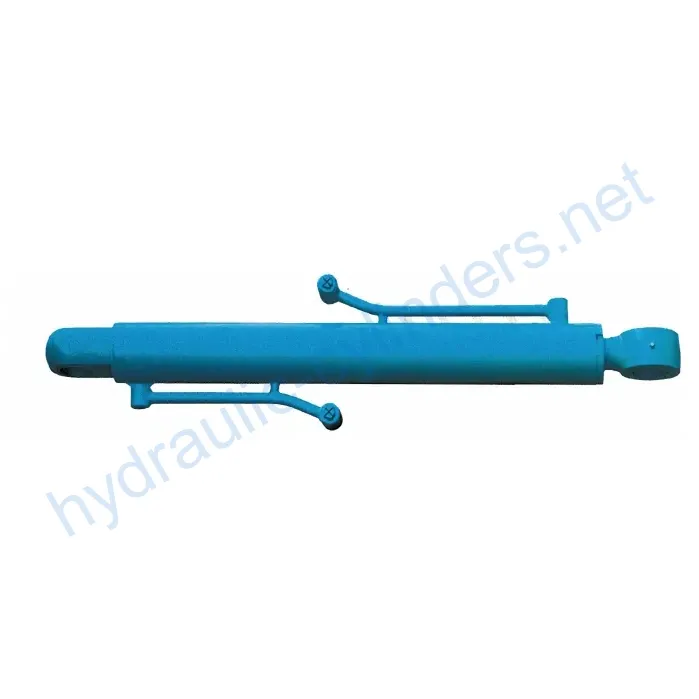

Bucket Cylinder For Xinyuan Wheel Excavator XY75W-8-9

Som en av tillverkarna, leverantörerna och exportörerna av mekaniska produkter erbjuder vi hydraulcylindrar och många andra produkter.

Vänligen kontakta oss för mer information.

E-post:sales@hydraulic-cylinders.net

Tillverkare, leverantör och exportör av hydraulcylindrar.

Bucket Cylinder For Xinyuan Wheel Excavator XY75W-8-9

Introduction

A bucket cylinder is a specially designed hydraulic cylinder used to control the movement of a bucket in heavy machinery such as excavators, backhoe excavators, and front-end loaders. Its main function is to enable the bucket to lift, lower, and tilt for easy handling of various materials. In the hydraulic system, the bucket cylinder achieves precise control of the bucket by changing the pressure of hydraulic oil, allowing operators to efficiently handle heavy loads and adapt to complex working environments and diverse operational requirements.

Features

- High Strength and Durability: Usually made of high-strength steel or aluminum, it can withstand high pressure and heavy loads, adapt to harsh working environments, and its design considers wear resistance and corrosion resistance to extend its service life.

- Efficient Hydraulic Operation: Smooth extension and retraction actions are achieved by utilizing the pressure of hydraulic oil, providing powerful pushing and pulling force, and suitable for handling heavy loads and complex operational tasks.

- Multiple Types: Single-acting (hydraulic used in only one direction) or double-acting (hydraulic used in both directions) cylinders can be selected according to operational needs. Some models are telescopic, allowing greater extension without increasing external dimensions, suitable for applications with limited space.

- Perfect Replacement: Our products can perfectly replace these hydraulic cylinders.

Applications

The bucket cylinder is important for excavating, loading, and moving soil or debris in construction equipment. In backhoe excavators, bucket cylinders help with excavation and lifting. In agricultural machinery, they are used for front-end loaders, scooping, lifting, and transporting soil, hay, and other materials. In excavators, bucket cylinders achieve digging actions by allowing the bucket to penetrate the soil. In front-end loaders, they help with lifting and dumping goods efficiently.

Design Considerations and Selection Criteria

- Bearing Capacity: The cylinder??s load-bearing capacity should be considered when selecting the appropriate cylinder for the application.

- Sealing: Various sealing components such as piston seals and rod seals should be used. Sealing components should be made of wear-resistant materials such as polyurethane and nitrile rubber. Cylinder bodies and threaded end surfaces should be finely processed to improve wear resistance, and hydraulic oil should be added regularly for lubrication.

- Durability: Consideration should be given to the design of the cylinder to ensure its durability. It should be made with high-strength and durable materials to resist wear and tear, corrosion, and other environmental factors.

- Safety: Safety should be a fundamental consideration in design and selection. The cylinder should be designed and selected for safe operation, and appropriate safety measures should be taken into account.

- Maintenance: Maintenance should be considered in the design and selection of cylinders. Cylinders should be designed for ease of maintenance and repairs, and scheduled maintenance should be performed to extend the service life of the cylinder.

Maintenance and Installation

The following are three common maintenance tasks:

- Regular inspection

- Proper lubrication

- Seal replacement and calibration check

Proper installation, lubrication, and adjustment are essential to ensure the longevity of the bucket cylinder. Proper alignment of the cylinder should be guided during installation, and appropriate installation brackets should be used to secure the cylinder. Recommended inspection, repair, and replacement procedures should be followed, and rebuilding services should be provided to enhance the service life of the product.

Safety and Environmental Considerations

Proper safety measures should be taken when operating the bucket cylinder to avoid accidents and ensure safe work practices. Environmental factors should also be considered when selecting and operating the cylinder to minimize adverse environmental impacts.

Diagnosis and Troubleshooting

The following are some common problems that may arise when using the bucket cylinder:

- Seal failure

- Excessive leakage

- Reduced operating efficiency

Troubleshooting tips and solutions should be provided to help diagnose and resolve problems effectively, and preventive measures should be taken to minimize potential issues.

About Our Company

We are a manufacturer of hydraulic cylinders that replace existing cylinders. Our company offers a complete range of products and has become one of the leading hydraulic cylinder manufacturers and wholesalers in domestic and foreign markets. We focus on excellent quality, rely on the industrialized production management strategy of a sophisticated manufacturing workshop, constantly improve the manufacturing platform of the workshop, perfect the quality production route of our products, and possess strong creativity. With the principles of high efficiency, high precision, and high quality, we strive to meet the diverse needs of our customers.

Professionalism

We are a team of professionals that are dedicated to providing excellent products and services to our customers. Our team includes engineers, technicians, and other skilled professionals who work hard to ensure that our products meet the highest standards of quality and reliability.

International Certifications

Our company has obtained various international certifications, including ISO9001, CE, and others, to ensure that our products meet the highest international standards.

Customization Services

We provide customization services to meet the unique needs of our customers. We work with our customers to design and manufacture hydraulic cylinders that meet their specific requirements and needs.

Production Equipment

Our company has invested heavily in advanced production equipment to ensure that we can manufacture high-quality hydraulic cylinders quickly and efficiently.

After-sales Service

We provide excellent after-sales service to ensure that our customers are satisfied with our products. We offer technical support, maintenance, repair, and rebuilding services to help our customers get the most out of our products.

Author: lyl.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: