Replacement Of AHC20257 Hydraulic Cylinder Kit

Som en av tillverkarna, leverantörerna och exportörerna av mekaniska produkter erbjuder vi hydraulcylindrar och många andra produkter.

Vänligen kontakta oss för mer information.

E-post:sales@hydraulic-cylinders.net

Tillverkare, leverantör och exportör av hydraulcylindrar.

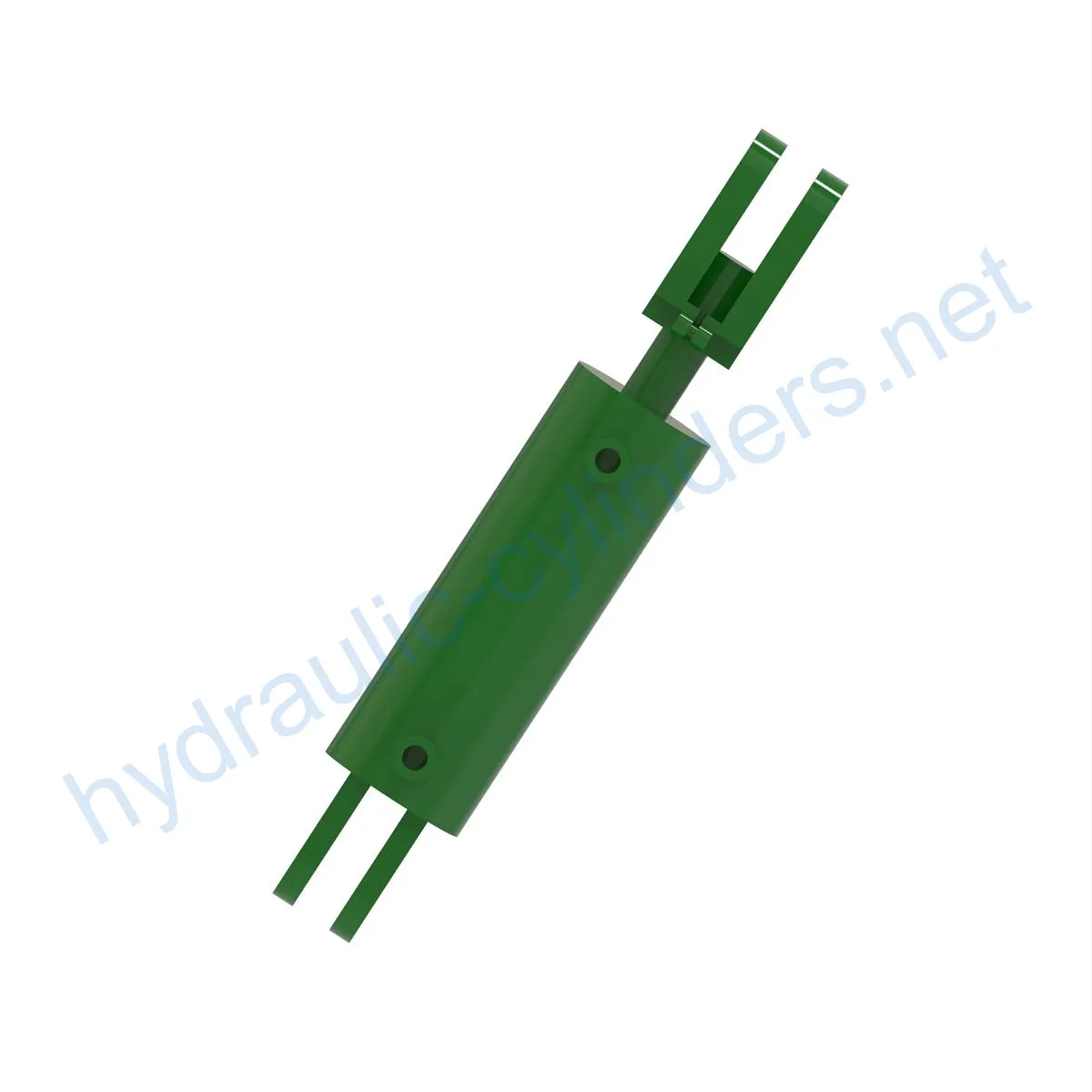

Replacement Of AHC20257 Hydraulic Cylinder Kit

The Replacement Of AHC20257 Hydraulic Cylinder Kit is a crucial component used in hydraulic systems. It is designed to replace damaged or worn-out hydraulic cylinders, ensuring the proper functioning of equipment in various applications.

Specifications

- Weight: 0.09 lb

- Height: 0.8 in

- Width: 6 in

- Length: 7.4 in

Model

The Replacement Of AHC20257 Hydraulic Cylinder Kit is compatible with the F4365 model.

Features

- Improved Equipment Performance: Replacing damaged or worn-out hydraulic cylinders can restore the normal operational capacity of equipment, ensuring optimal performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders can reduce safety hazards associated with cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: New cylinder designs often incorporate better overload protection mechanisms, enhancing overall safety.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts in the market.

We specialize in producing this hydraulic cylinder kit, offering a perfect replacement solution for these hydraulic cylinders.

Applications

The Replacement Of AHC20257 Hydraulic Cylinder Kit finds applications in various industries. Here are a few examples:

- Excavators: Hydraulic cylinders on the excavator’s arm or bucket may get damaged due to prolonged use or overload, requiring replacement to restore normal operations.

- Cranes: Hydraulic cylinders in the crane’s boom are subjected to frequent lifting and lowering, which can lead to wear and tear. Regular replacement is necessary to ensure safety.

- Tractors: Hydraulic cylinders in the front-end loader of a tractor may experience leaks or performance degradation during continuous lifting and tilting operations, necessitating replacement.

- Harvesters: High-pressure hydraulic systems in harvesters put a strain on cylinders, which can lead to fatigue and damage. Timely replacement is essential to maintain work efficiency.

- Automated Production Lines: Hydraulic cylinders are used to control robotic arms and other automated equipment. Cylinder failures can significantly impact production efficiency and require immediate replacement.

Maintenance Tasks

Regular maintenance is crucial to ensure the longevity of the Replacement Of AHC20257 Hydraulic Cylinder Kit. Here are three common maintenance tasks:

- Periodic Inspections: Regularly inspecting the hydraulic cylinders for any signs of damage or wear helps identify issues early on and prevent potential failures.

- Proper Lubrication: Adequate lubrication is essential to minimize friction and ensure smooth operation. Periodically lubricating the cylinders with the recommended hydraulic oil is recommended.

- Seal Replacement and Calibration Checks: Over time, seals may deteriorate, compromising the cylinder’s performance. Regularly replacing seals and conducting calibration checks is necessary to maintain optimal functionality.

During installation, it is important to provide proper guidance for aligning the cylinder, recommend the use of suitable installation brackets to secure the cylinder, and follow recommended inspection, repair, and replacement procedures. We offer replacement parts and rebuilding services to enhance the lifespan of your hydraulic cylinders.

Safety Considerations and Environmental Factors

When using the Replacement Of AHC20257 Hydraulic Cylinder Kit, it is important to adhere to safety measures to prevent accidents and ensure worker safety. Properly following safety protocols and guidelines when handling hydraulic cylinders is essential. Additionally, considering environmental factors and using appropriate measures to minimize potential environmental impact is crucial.

Failure Diagnosis and Common Issues

Common hydraulic cylinder issues and troubleshooting tips:

- Leakage: Inspect the cylinder for any signs of leakage and check seals for damage. Replace faulty seals to resolve leakage issues.

- Slow or Inconsistent Movement: Check for insufficient lubrication or contamination in the hydraulic fluid. Ensure proper lubrication and clean the hydraulic system if necessary.

- Unusual Noises or Vibrations: Inspect the cylinder and connections for loose parts or misalignment. Tighten any loose components or realign as needed.

These troubleshooting tips can help readers effectively diagnose and resolve common hydraulic cylinder problems. Additionally, providing preventive measures can minimize potential issues and optimize performance.

Design Considerations and Selection Criteria

When selecting hydraulic cylinders, several design considerations should be kept in mind:

- Load-bearing Capacity: Ensure the cylinder’s load-bearing capacity is compatible with the intended application.

- Sealing and Durability: Look for cylinders with durable seals and components to withstand demanding operating conditions.

- Safety: Consider cylinders with built-in safety features to prevent accidents and ensure operator protection.

- Maintainability: Opt for cylinders that are easy to maintain and repair, reducing downtime and increasing efficiency.

Sealing and Lubrication

The Replacement Of AHC20257 Hydraulic Cylinder Kit incorporates various sealing components, including piston seals and rod seals made of wear-resistant materials like polyurethane and nitrile rubber. The cylinder body and threaded ends undergo precise surface treatments to enhance wear resistance. Regularly lubricating the cylinder with the recommended hydraulic oil helps maintain optimal performance.

Regular Inspections and Preventive Maintenance

Proper installation, lubrication, and adjustment are crucial for the longevity of the Replacement Of AHC20257 Hydraulic Cylinder Kit. Providing guidance on aligning the cylinder correctly, recommending the use of suitable installation brackets for securing the cylinder, and suggesting inspection, repair, and replacement procedures are essential. We offer guidance for the correct installation and provide tips to extend the lifespan of your hydraulic cylinders.

Company Overview

We are a leading manufacturer and wholesale distributor of hydraulic cylinders in the domestic and international markets. Our extensive product range caters to diverse industry needs.

Our Strengths:

- Professionalism: We have a team of experts dedicated to delivering high-quality hydraulic cylinders.

- International Certifications: Our products meet rigorous international standards, ensuring reliability and performance.

- Customization Services: We offer tailored solutions to meet specific customer requirements.

- Advanced Production Equipment: Our state-of-the-art manufacturing facilities enable us to produce top-notch hydraulic cylinders.

- Superior After-Sales Service: We provide comprehensive after-sales support, including component replacements and rebuilding services.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: