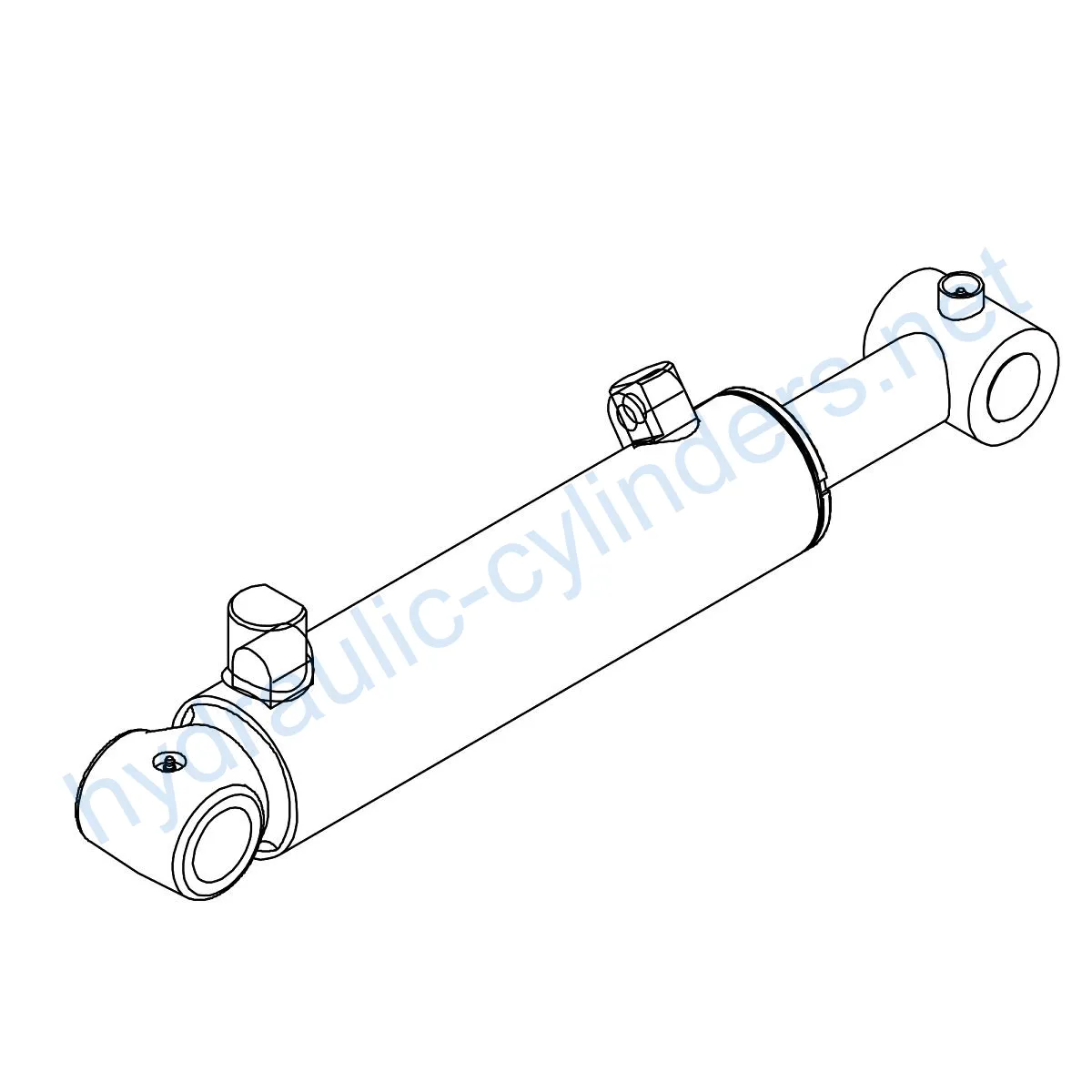

Replacement Of F059958 Hydraulic Cylinder

Hidrolik silindir üreticilerinden, tedarikçilerinden ve mekanik ürünlerin ihracatçılarından biri olarak, hidrolik silindirler ve diğer birçok ürünü sunuyoruz.

Ayrıntılar için lütfen bizimle iletişime geçin.

Posta:sales@hydraulic-cylinders.net

Hidrolik silindir üreticisi tedarikçisi ihracatçısı.

Introduction to Replacement Of F059958 Hydraulic Cylinder

The Replacement Of F059958 Hydraulic Cylinder is a critical component used in various industrial applications. It is designed to provide hydraulic power and control movements in machinery and equipment. The hydraulic cylinder plays a crucial role in ensuring the smooth operation and performance of the equipment.

Specifications and Models

Weight: 51 lb

Height: 4 in

Width: 5.5 in

Length: 23 in

Compatible Models: 810D, 810E, 910G, 1010D, 1010E, 1010G, 1110D, 1110E, 1110G, 1210E, 1210G, 1410D, 1490D, 1510E, 1510G, 1710D, 1711D, 1910E, 1910G, CF1, CF7

Key Features

- Improved Equipment Performance: Replacing damaged or worn hydraulic cylinders can restore the equipment’s normal operating capabilities, ensuring optimal performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: New cylinder designs often incorporate better overload protection mechanisms, enhancing safety during operation.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it easy to obtain replacement parts in the market.

Applications

The Replacement Of F059958 Hydraulic Cylinder finds its applications in various industries. Here are a few examples:

- Excavators: Hydraulic cylinders in excavator arms or buckets may get damaged due to prolonged use or overload, requiring replacement to restore normal operation.

- Cranes: Hydraulic cylinders in crane boom arms can experience wear and tear during frequent lifting and lowering processes, necessitating regular replacement for safety purposes.

- Tractors: Front-end loader hydraulic cylinders in tractors can develop leaks or reduced performance during continuous lifting and tilting operations, calling for replacement.

- Harvesters: High hydraulic pressure in harvesting processes can lead to cylinder fatigue, causing damage that needs immediate replacement to maintain work efficiency.

- Automated Production Lines: Hydraulic cylinders are used to control robotic arms and other automated equipment. Cylinder failures can lead to reduced production efficiency, requiring immediate replacement.

- Die-casting Machines: Hydraulic cylinders in die-casting machines may experience performance degradation under high pressure and temperature conditions. Regular replacement ensures product quality.

- Mining Equipment: Hydraulic cylinders are used for lifting and moving heavy loads in mining equipment. Due to harsh working environments, regular inspection and replacement are necessary to avoid equipment failures.

- Bulldozers: Wear on hydraulic cylinders in bulldozer blades can decrease pushing capacity, necessitating timely replacement to maintain operational efficiency.

Maintenance Tasks

Regular maintenance is vital for the longevity and optimal performance of the Replacement Of F059958 Hydraulic Cylinder. Here are three common maintenance tasks:

- Regular Inspection: Scheduled inspections ensure early detection of any issues and allow for prompt repairs or replacements.

- Proper Lubrication: Adequate lubrication of the cylinder’s moving parts reduces friction, preventing premature wear and optimizing performance.

- Seal Replacement and Calibration Check: Periodic replacement of seals and calibration checks ensure the cylinder maintains optimal functionality.

Safety Considerations and Environmental Factors

When operating the Replacement Of F059958 Hydraulic Cylinder, it is crucial to follow safety measures to prevent accidents and ensure the well-being of personnel. This includes:

- Using appropriate personal protective equipment (PPE) when working with hydraulic systems.

- Adhering to proper lockout/tagout procedures to isolate energy sources during maintenance or repair.

- Disposing of used hydraulic fluids and other materials in an environmentally responsible manner.

Fault Diagnosis and Common Issues

Identifying faults and resolving issues promptly is essential for the optimal performance of the Replacement Of F059958 Hydraulic Cylinder. Here are some common problems:

- Leakage: Hydraulic fluid leakage can occur due to worn seals or damaged components. Regular inspection and seal replacement can mitigate this issue.

- Slow Operation: Sluggish cylinder movement may indicate a lack of lubrication or internal contamination. Proper lubrication and cleaning can help restore normal operation.

- Excessive Noise or Vibration: Abnormal noise or vibration may suggest loose connections or misalignment. Inspection and adjustment can resolve these issues.

- Insufficient Power: Inadequate pushing or lifting force may indicate internal cylinder damage. Timely replacement of damaged components can rectify this problem.

Troubleshooting Tips and Preventive Measures

To assist readers in diagnosing and resolving issues effectively, here are some troubleshooting tips and preventive measures for the Replacement Of F059958 Hydraulic Cylinder:

- Ensure proper installation, lubrication, and adjustment for optimal performance.

- Provide guidance on aligning the cylinder correctly during installation.

- Recommend the use of suitable mounting brackets to secure the cylinder.

- Suggest inspection, repair, and replacement procedures, along with available parts and rebuild services.

- Share techniques to extend the lifespan of the cylinder, such as appropriate keyword usage.

Design Considerations and Selection Criteria

When designing and selecting hydraulic cylinders, several factors should be taken into account, including:

- Load Bearing Capacity: The cylinder must be capable of handling the expected load without compromising performance.

- Sealing: Various sealing components, such as piston seals and rod seals, should be carefully chosen to ensure proper function and minimize leakage.

- Durability: The cylinder should be constructed using durable materials and undergo appropriate surface treatments to withstand harsh operating conditions.

- Safety: Incorporating safety features, such as overload protection mechanisms, enhances the overall safety of the system.

- Maintainability: Easy access to components and the availability of spare parts simplify maintenance and facilitate timely repairs.

Sealing and Lubrication

The Replacement Of F059958 Hydraulic Cylinder utilizes various sealing elements, including piston seals and rod seals, to ensure proper functioning. These seals are made of wear

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: