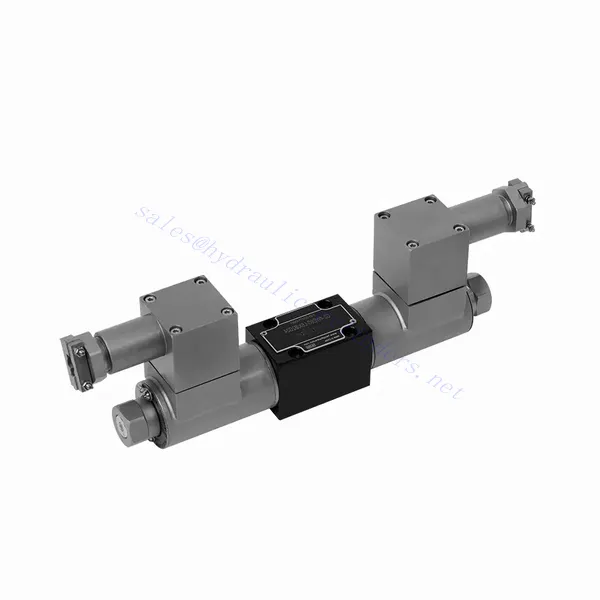

GWE Series Explosion-proof Solenoid Directional Hydraulic Valve

Hidrolik silindir üreticilerinden, tedarikçilerinden ve mekanik ürünlerin ihracatçılarından biri olarak, hidrolik silindirler ve diğer birçok ürünü sunuyoruz.

Ayrıntılar için lütfen bizimle iletişime geçin.

Posta:sales@hydraulic-cylinders.net

Hidrolik silindir üreticisi tedarikçisi ihracatçısı.

GWE Series Explosion-proof Solenoid Directional Hydraulic Valve

The GWE series explosion-proof solenoid directional hydraulic valve is a cutting-edge product designed to ensure safety and efficiency in hydraulic systems operating in hazardous environments. With its explosion-proof capabilities and reliable performance, this valve offers precise control, enhanced safety features, and optimal fluid flow management.

The GWE series explosion-proof solenoid directional hydraulic valve is a remarkable solution for achieving safety and efficiency in hydraulic systems operating in hazardous environments. With its explosion-proof design, solenoid technology, directional control capabilities, and versatility, this valve provides reliable performance and precise fluid flow management. By following the recommended usage methods and adhering to regular maintenance practices, the GWE series valve ensures safe and efficient operation in explosive atmospheres. Upgrade your hydraulic system with the GWE series explosion-proof solenoid directional hydraulic valve and experience the benefits of enhanced safety and optimized fluid flow control.

GWE Series Explosion-proof Solenoid Directional Hydraulic Valve Key Characteristics:

- Explosion-proof Design:

- The GWE series hydraulic valve is precisely engineered to operate safely in explosive atmospheres, such as those containing flammable gases or dust.

- It complies with stringent safety standards and certifications, ensuring reliable performance and preventing potential ignition sources.

- Solenoid Technology:

- This hydraulic valve utilizes solenoid technology for precise control of fluid flow.

- The electromagnetic coil generates a magnetic field that actuates the valve, enabling quick response times and accurate positioning.

- Directional Control:

- The GWE series valve provides efficient directional control of hydraulic fluid flow, allowing for the activation and deactivation of specific hydraulic actuators.

- It ensures smooth and reliable operation of various hydraulic functions, such as cylinder extension and retraction or motor direction changes.

- Versatility and Compatibility:

- This hydraulic valve is highly versatile and compatible with various systems and applications.

- It can be integrated into industrial machinery, mobile equipment, and automation systems operating in hazardous environments.

GWE Series Explosion-proof Solenoid Directional Hydraulic Valve Parameter:

| Specifications | NG6 | NG10 | ||

| Installation position | Optional | Optional | ||

| Environment temperature | ℃ | -30 to +50(NBR seal) | ||

| -20 to +50(FKM seal) | ||||

| Weight | Single solenoid valve | kg | 2.6 | 5.9 |

| Double solenoid valve | kg | 4.3 | 8.9 | |

| Maximum working pressure | Port P, A, B | bar | 350 | 315 |

| Port T | bar | 210 | ||

| When the working pressure exceeds the allowable pressure, the valves with symbols a and B must use T as the oil release port. | ||||

| Max. flow-rate | L/min | 80 | 120 | |

| V type | mm2 | / | 11(A/B → T);10.3(P → A/B) | |

| Flowarea (switching neutral position ) | Q type | mm2 | for symbol Q 6% of nominal cross section | 2.5(A/B → T) |

| W type | mm2 | for symbol W 3% of nominal cross section | 5.5(A/B → T) | |

| Fluid | Mineral oil suitable for NBR and FKM seal | |||

| Phosphate ester for FKM seal | ||||

| Fluid temperature range | ℃ | -30 to +80(NBR seal) | ||

| -20 to +80(FKM seal) | ||||

| Viscosity range | mm2/s | 2.8 to 500 | ||

| Degree of contamination | Maximum permissible degree of fluid contamination: Class 9. NAS 1638 or 20/18/15, ISO4406 | |||

GWE Series Explosion-proof Solenoid Directional Hydraulic Valve Advantages:

NG6

• Direct explosion proof solenoid slide valve as standard type

• Installation face follow DIN 24340 A, ISO 4401 and CETOP-RP 121H

• Wet DC explosion proof solenoid

• Explosion proof solenoid can rotate 90°

• Replace coil without releasing oil

NG10

• Explosion proof solenoid slide valve as standard typen

• Installation face follow DIN 24340 A, ISO 4401 and CETOP-RP 121H

• Wet DC explosion proof solenoid

• Explosion proof solenoid can rotate 90°

• Replace coil without releasing oil

Usage Method Of GWE Series Explosion-proof Solenoid Directional Hydraulic Valve:

- Hazardous Area Assessment:

- Conduct a thorough assessment of the hazardous area to identify the specific explosion-proof requirements and classification.

- Determine the appropriate safety measures and precautions needed to comply with the regulations.

- Valve Selection:

- Select the GWE Series Valve with the appropriate specifications, considering pressure ratings, flow capacity, and voltage requirements.

- Ensure compatibility with the hydraulic system and the specific hazardous environment.

- Installation:

- Follow the manufacturer’s instructions for properly installing the GWE series valve in the hydraulic system.

- Ensure secure mounting and proper electrical connections, adhering to the recommended torque values and wiring guidelines.

- Control and Activation:

- Utilize the recommended control method, such as electrical signals or remote activation, to operate the GWE Series Valve.

- Connect the valve to a suitable power source and control system, following the provided wiring diagrams.

How Does A Hydraulic Check Valve Work?

A hydraulic check valve, also known as a one-way or non-return valve, is a crucial component in hydraulic systems that allows fluid flow in only one direction while preventing backflow. It ensures the proper operation and safety of hydraulic systems by preventing the reverse flow of fluid, maintaining pressure, and controlling the movement of hydraulic actuators. Here’s an overview of how a hydraulic check valve works:

- Valve Structure:

- A hydraulic check valve typically consists of a valve body, seat, and a movable element such as a ball, disc, or poppet.

- The valve body contains inlet and outlet ports through which the fluid enters and exits the valve.

- The valve seat is a sealing surface where the movable element makes contact to block or allow fluid flow.

- Flow Direction:

- Hydraulic check valves are designed to allow fluid flow in one direction (forward flow) and prevent flow in the opposite direction (reverse flow).

- The valve body is marked with an arrow indicating the direction of permissible flow.

- Forward Flow:

- When fluid pressure in the hydraulic system exceeds a certain threshold, it overcomes the force exerted by the movable element against the valve seat.

- The fluid pushes the movable element away from the valve seat, creating an open pathway for fluid flow through the valve.

- Reverse Flow Prevention:

- In the absence of forward flow or when the pressure on the outlet side of the valve exceeds the inlet side, the movable element is forced against the valve seat.

- The sealing surface of the valve seat prevents fluid from flowing in the reverse direction by creating a tight seal.

- Check Valve Types:

- Ball Check Valve: It consists of a ball that rests on the valve seat. When fluid pressure exceeds the force holding the ball against the seat, the ball lifts, allowing fluid to pass through.

- Swing Check Valve: It has a hinged disc that swings open to allow forward flow and swings closed under reverse flow conditions.

- Poppet Check Valve: It features a spring-loaded poppet that lifts off the valve seat to enable flow in the forward direction and closes to block reverse flow.

- Applications:

- Hydraulic check valves are used in various hydraulic systems to prevent backflow, maintain pressure, and control the movement of hydraulic actuators.

- They are commonly found in hydraulic cylinders, pumps, motors, control valves, and other components to ensure proper system operation.

- Benefits:

- Preventing Backflow: The primary function of a hydraulic check valve is to prevent reverse flow, which can cause system instability, damage, or inefficient operation.

- Pressure Maintenance: Check valves help maintain pressure by preventing pressure loss due to backflow.

- Control and Safety: By allowing flow in one direction only, check valves enable precise control of hydraulic systems and contribute to their safe operation.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: