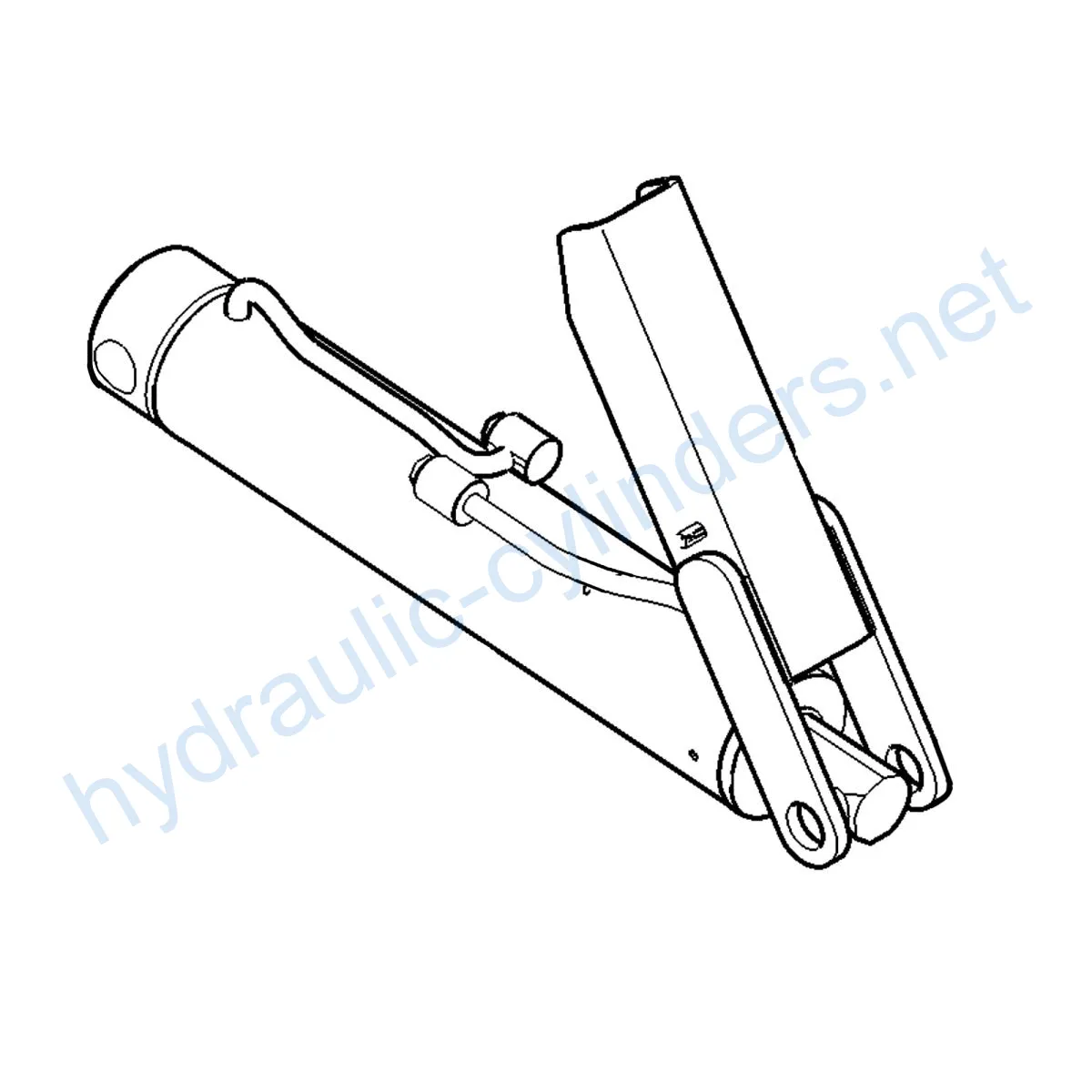

Replacement Of AFH214102 Hydraulic Cylinder

Hidrolik silindir üreticilerinden, tedarikçilerinden ve mekanik ürünlerin ihracatçılarından biri olarak, hidrolik silindirler ve diğer birçok ürünü sunuyoruz.

Ayrıntılar için lütfen bizimle iletişime geçin.

Posta:sales@hydraulic-cylinders.net

Hidrolik silindir üreticisi tedarikçisi ihracatçısı.

Replacement Of AFH214102 Hydraulic Cylinder

The Replacement Of AFH214102 Hydraulic Cylinder is a crucial component used in various machines, such as W110, W150, and W155 models. This hydraulic cylinder plays a vital role in providing the necessary force for lifting, pushing, and moving heavy loads. It ensures smooth and efficient operation of the equipment.

Specifications

- Weight: 38.34 lb

- Height: 3.8 in

- Width: 5 in

- Length: 23.5 in

Models

- W110

- W150

- W155

Features

- Improved Equipment Performance: Replacing damaged or worn hydraulic cylinders can restore the equipment’s normal operational capabilities, ensuring optimal performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders reduces safety hazards associated with cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: New cylinder designs often incorporate better overload protection mechanisms, enhancing safety during operation.

- Quick Installation: Modern hydraulic cylinders are designed with ease of installation and replacement in mind, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts in the market.

We are capable of producing this hydraulic cylinder and offer a perfect replacement for the mentioned models. Our products are designed to meet the highest standards of quality and performance.

Applications

Here are three common applications where the Replacement Of AFH214102 Hydraulic Cylinder is used:

- Excavators: In excavators, hydraulic cylinders in the arm or bucket may get damaged due to extensive use or overload. Replacement is necessary to restore normal operation.

- Cranes: Hydraulic cylinders in crane boom experience wear and tear during frequent lifting and lowering. Regular replacement is required to ensure safety.

- Tractors: Hydraulic cylinders in front-end loaders of tractors may develop leaks or performance degradation due to continuous lifting and tilting operations. Replacement is necessary.

These are just a few examples, but the Replacement Of AFH214102 Hydraulic Cylinder finds applications in various industries, including harvesting machines, automated production lines, die-casting machines, mining equipment, bulldozers, and more.

Maintenance Tasks

Regular maintenance of the hydraulic cylinder is essential for optimal performance and longevity. Here are three common maintenance tasks:

- Regular Inspection: Periodically inspect the cylinder for any signs of damage or leaks. Regular inspections help identify potential issues before they escalate.

- Proper Lubrication: Adequate lubrication is necessary to minimize friction and ensure smooth operation. Use the recommended hydraulic oil and lubricate the cylinder as per the manufacturer’s guidelines.

- Seal Replacement and Calibration Check: Over time, seals may wear out and affect the cylinder’s performance. Replace worn seals and periodically check the cylinder’s calibration to maintain optimal functionality.

By following these maintenance tasks and ensuring correct installation, lubrication, and adjustment, you can prolong the lifespan of the Replacement Of AFH214102 Hydraulic Cylinder and avoid potential issues.

Safety Considerations and Environmental Factors

When working with hydraulic cylinders, it is crucial to prioritize safety measures. The use of appropriate safety precautions when handling the cylinders reduces the risk of accidents and injuries. Additionally, considering environmental factors and using environmentally friendly materials and practices contribute to sustainable operations.

Troubleshooting and Common Issues

Understanding the potential faults and common problems with hydraulic cylinders can help diagnose and address issues effectively. Here are some common troubleshooting points:

- Leakage: If the hydraulic cylinder is leaking fluid, check for damaged seals or fittings. Replace them if necessary.

- Slow Operation: Slow or sluggish cylinder movement could indicate insufficient lubrication or internal contamination. Ensure proper lubrication and clean the cylinder if needed.

- Erratic Movements: Unpredictable or irregular cylinder movements might be caused by air trapped in the system or a faulty control valve. Bleed the air from the system or inspect the valve for any defects.

For each troubleshooting point, it is essential to provide guidance on fault handling, problem-solving techniques, and preventive measures to minimize potential issues.

Design Considerations and Selection Criteria

When choosing a hydraulic cylinder, certain design considerations and selection criteria should be taken into account:

- Load Capacity: The hydraulic cylinder must have the appropriate load-carrying capacity to handle the required weight.

- Sealing and Durability: Ensuring proper sealing and durability of the cylinder is crucial for long-term performance and leak prevention.

- Safety: Hydraulic cylinders should be designed with safety features to prevent accidents and potential hazards during operation.

- Maintainability: Easy access for maintenance, repair, and replacement is vital to minimize downtime and maximize efficiency.

By considering these factors, you can select the right hydraulic cylinder for your specific application, ensuring optimal performance and longevity.

Sealing and Lubrication

The Replacement Of AFH214102 Hydraulic Cylinder utilizes various sealing components, such as piston seals and rod seals, made of wear-resistant materials like polyurethane and nitrile rubber. The cylinder body and threaded ends undergo meticulous surface treatments to enhance wear resistance. Proper lubrication is essential to ensure smooth operation and prevent premature wear. Regularly adding the appropriate amount of hydraulic oil for lubrication is recommended.

Regular Inspection and Preventive Maintenance

Regularly inspecting hydraulic cylinders is crucial for identifying potential issues and taking preventive measures. Here are some recommended maintenance practices:

- Ensure Proper Installation: Provide proper alignment guidance during installation and recommend the use of suitable mounting brackets to secure the cylinder in place.

- Recommended Inspection, Repair, and Replacement Procedures: Offer guidelines for inspecting and repairing the cylinder, as well as replacing components and providing rebuild services to maximize the lifespan of the hydraulic cylinder.

- Tips for Extending the Cylinder’s Usage Life: Share techniques and tips to enhance the longevity of the hydraulic cylinder, such as optimizing usage, maintaining cleanliness, and promptly addressing any abnormalities.

Product Installation Guide

To ensure successful installation of the Replacement Of AFH214102 Hydraulic Cylinder, follow these steps:

- Prepare the mounting area and ensure it is clean and free from debris.

- Align the cylinder properly with the equipment, ensuring it is securely positioned.

- Attach the hydraulic hoses or fittings, following the manufacturer’s instructions.

- Check for any leaks after installation, and if present, address them promptly.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: