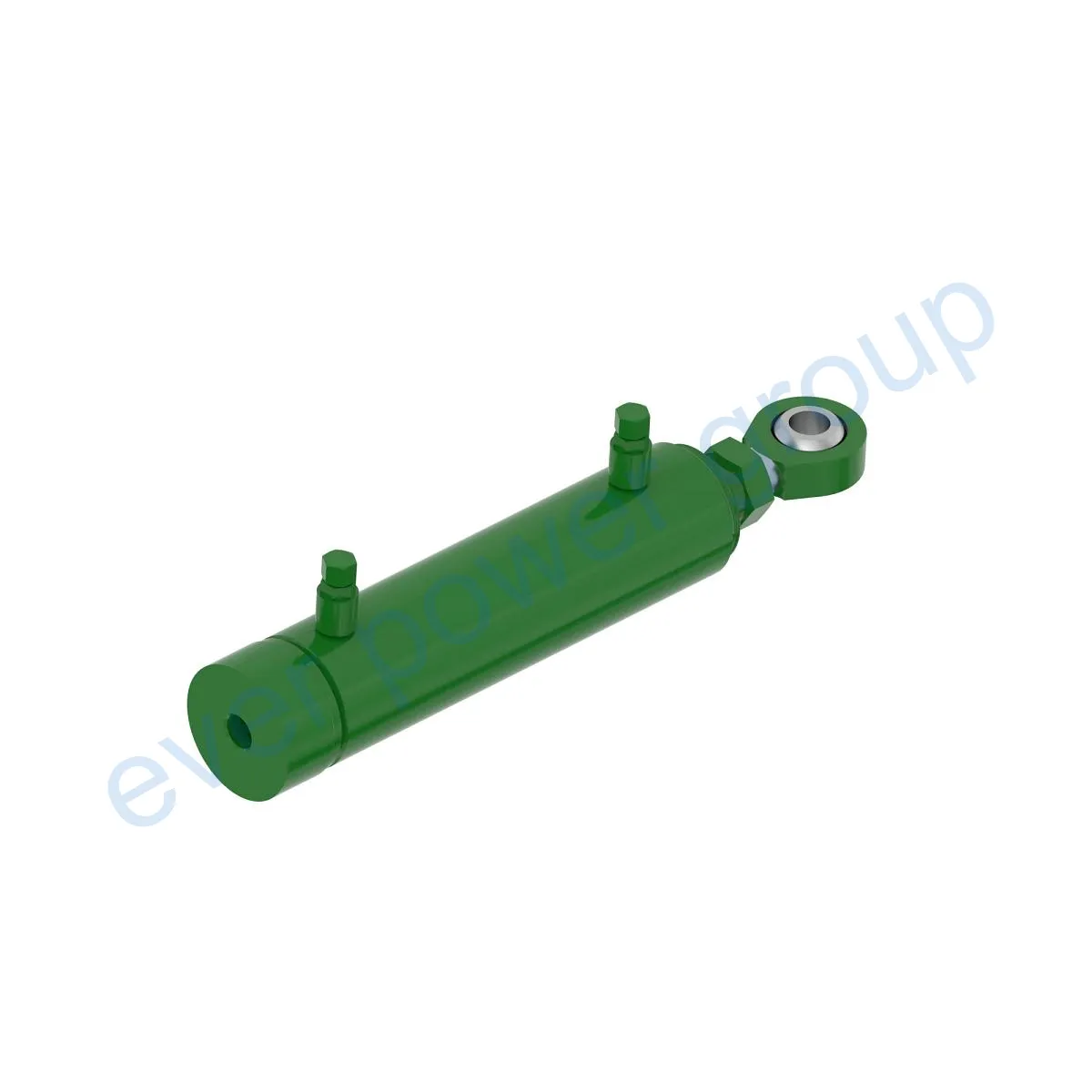

Replacement Of AHC19564 Hydraulic Cylinder

Hidrolik silindir üreticilerinden, tedarikçilerinden ve mekanik ürünlerin ihracatçılarından biri olarak, hidrolik silindirler ve diğer birçok ürünü sunuyoruz.

Ayrıntılar için lütfen bizimle iletişime geçin.

Posta:sales@hydraulic-cylinders.net

Hidrolik silindir üreticisi tedarikçisi ihracatçısı.

Replacement Of AHC19564 Hydraulic Cylinder

First, let’s introduce the product and define what this hydraulic cylinder is and its purpose. The Replacement Of AHC19564 Hydraulic Cylinder is a crucial component used in various applications to provide linear force and motion. It plays a vital role in the proper functioning of equipment.

Specifications

- Weight: 29 lb

- Height: 5.8 in

- Length: 20 in

Compatible Models

- 4730

- M4030

- M4040

Product Features

- Durable construction for long-lasting performance

- Precise engineering for efficient operation

- High load-bearing capacity

- Excellent sealing properties for leak-free operation

- Easy maintenance and repair

Our company specializes in producing replacement hydraulic cylinders that perfectly substitute the AHC19564 model. With our expertise, we guarantee top-notch quality and reliability.

Applications

This hydraulic cylinder finds extensive use in various industries:

Construction

Commonly used in cranes, hoists, and elevators where a secure and stable fixation of heavy loads is necessary.

Manufacturing

Utilized in presses where materials undergo high-pressure forming, requiring a secure hold during the machining process.

Transportation

Integrated into stabilizers and jacks of vehicles to ensure safety during maintenance or transportation.

Aviation

Essential for landing gear systems, securely fixing the landing gear in the appropriate position during takeoff and landing.

Design Considerations and Selection Criteria

When it comes to designing and selecting hydraulic cylinders, several key factors must be taken into account:

Load-Bearing Capacity

The cylinder must withstand the specified load without failure or deformation.

Sealing

Various sealing components, such as piston seals and rod seals, should be utilized to ensure leak-free performance. Polyurethane and nitrile rubber are commonly used materials for seals.

Durability

The cylinder body and threaded ends should undergo precise treatment to enhance wear resistance and overall durability.

Safety

Ensuring that the hydraulic cylinder meets safety standards to prevent accidents and injuries during operation.

Maintenance

Regular lubrication with appropriate hydraulic oil and periodic inspections are essential to maintain optimal performance and extend the cylinder’s lifespan.

Regular Inspection and Preventative Maintenance

To ensure the longevity of the hydraulic cylinder, consider the following maintenance measures:

Proper Installation

Provide accurate alignment instructions during installation and recommend the use of suitable mounting brackets to secure the cylinder.

Recommended Maintenance Tasks

- Regular inspections to identify any potential issues

- Appropriate lubrication to reduce friction and wear

- Seal replacement when necessary

- Calibration checks to maintain optimal performance

These maintenance tasks are vital to guarantee the efficient operation and extended lifespan of the hydraulic cylinder.

Safety Considerations and Environmental Factors

When working with hydraulic cylinders, it is crucial to prioritize safety measures. Proper handling and adherence to safety protocols reduce the risk of accidents and injuries in the workplace.

Troubleshooting and Common Issues

In the event of problems, it is important to diagnose and address them promptly. Here are some common issues that may arise:

Leakage

If there is hydraulic fluid leakage, inspect the seals and replace them if necessary. Ensure the cylinder is properly lubricated.

Insufficient Force

If the cylinder fails to provide sufficient force, check for any blockages or restrictions in the hydraulic system. It may be necessary to clean or replace components.

Erratic Movement

If the cylinder exhibits unpredictable or uneven movement, inspect the hydraulic lines and connections for any leaks or damage. Check for proper alignment and make adjustments as needed.

Conclusion

Our company takes pride in being a leading manufacturer and wholesale distributor of hydraulic cylinders. We offer a comprehensive range of products, ensuring top-notch quality and unmatched customer satisfaction.

About Us

With our expertise, international certifications, customized services, state-of-the-art production equipment, and exceptional after-sales support, we have established ourselves as a trusted name in the industry.

Author: lyl

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: