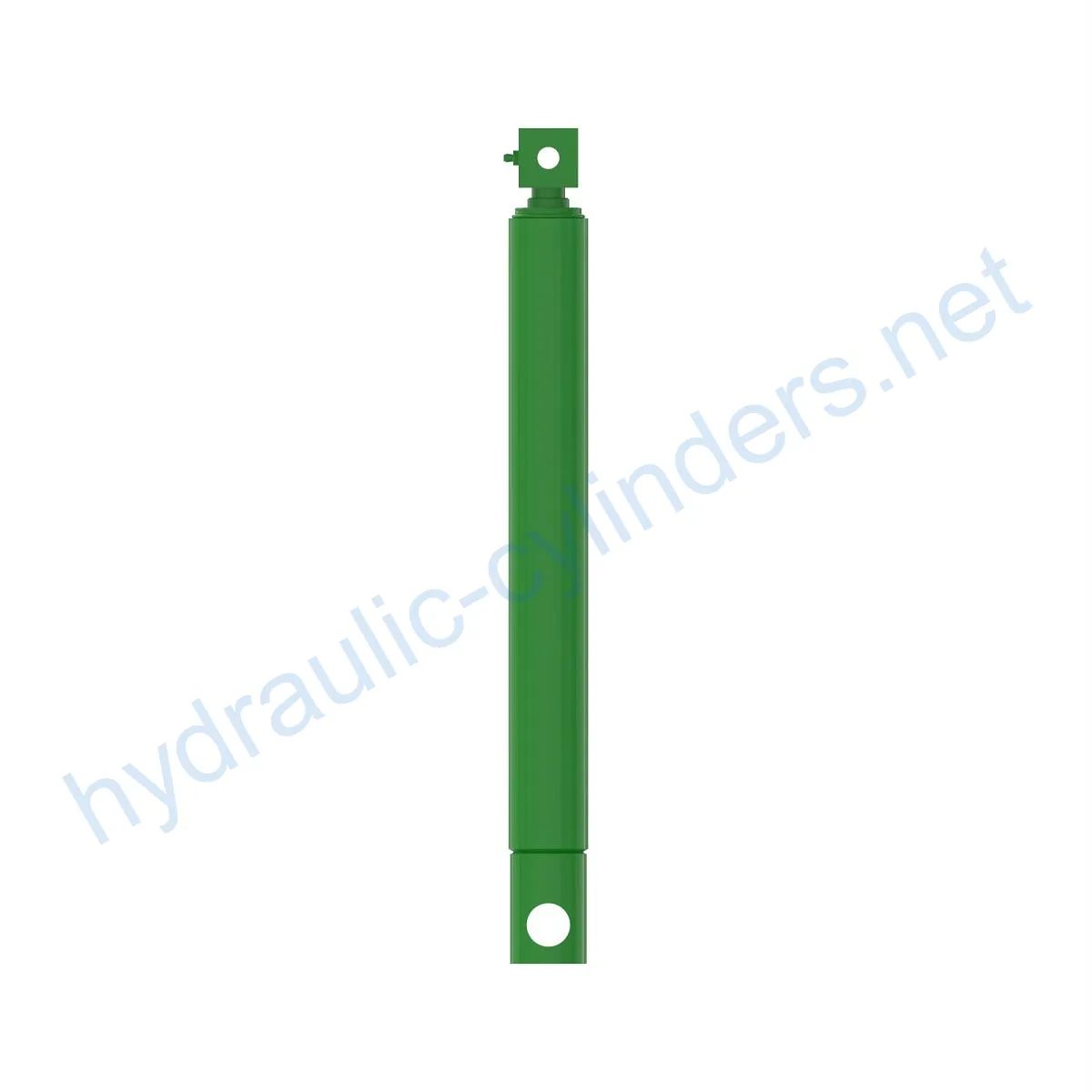

Replacement Of AW14971 Fork Hydraulic Cylinder

Hidrolik silindir üreticilerinden, tedarikçilerinden ve mekanik ürünlerin ihracatçılarından biri olarak, hidrolik silindirler ve diğer birçok ürünü sunuyoruz.

Ayrıntılar için lütfen bizimle iletişime geçin.

Posta:sales@hydraulic-cylinders.net

Hidrolik silindir üreticisi tedarikçisi ihracatçısı.

Introduction:

This article provides an overview of the Replacement Of AW14971 Fork Hydraulic Cylinder product. The article will define what the hydraulic cylinder is and its functions. Moreover, it will expand on the specifications and models of the product. Additionally, the article will describe the features of the product, such as improving equipment performance, enhancing safety, overload protection, quick installation, and standardized components. Furthermore, the article will explore the applications of the hydraulic cylinder, including excavators, cranes, tractors, harvesters, automated production lines, and mining equipment. The article will also discuss the importance of regular inspection, proper lubrication, seal replacement, and calibration checks. Additionally, the article will provide tips for troubleshooting and diagnosing common problems.

Product Definition:

The Replacement Of AW14971 Fork Hydraulic Cylinder is a mechanical device used to convert hydraulic power into mechanical force and motion. It is commonly used in industrial applications such as excavators, cranes, tractors, harvesters, automated production lines, and mining equipment. The hydraulic cylinder has a hollow cylindrical casing with a piston and a rod inside. The cylinder converts fluid pressure into linear motion and force to operate the machine’s components.

Specifications and Models:

The Replacement Of AW14971 Fork Hydraulic Cylinder weighs 20.75 lbs and has a height of 2.81 inches, width of 4.6 inches, and length of 22 inches. It is compatible with machine models 146, 148, 158, and 168.

Features:

The Replacement Of AW14971 Fork Hydraulic Cylinder has several features that make it an essential component in industrial applications. The key features include:

1. Improved Equipment Performance: Replacing damaged or worn hydraulic cylinders can restore a machine’s normal operating ability, ensuring its performance in various applications.

2. Enhanced Safety: Regular replacement of hydraulic cylinders can reduce safety hazards caused by cylinder failure and ensure the safety of operators and equipment.

3. Overload Protection: New cylinder designs usually consider better overload protection mechanisms, enhancing safety.

4. Quick Installation: Modern hydraulic cylinder designs typically consider ease of installation and replacement, reducing downtime.

5. Standardized Components: Many hydraulic cylinders are standardized products, making it easy to obtain replacement parts in the market.

Applications:

The Replacement Of AW14971 Fork Hydraulic Cylinder has various applications in industrial machines. Here are a few examples:

1. Excavators: Hydraulic cylinders in excavator arms or buckets may become damaged due to prolonged use or overload and require replacement to restore normal operation.

2. Cranes: Hydraulic cylinders in crane booms may wear out during frequent lifting and lowering processes, requiring regular replacement to ensure safety.

3. Tractors: Front-end loader hydraulic cylinders in tractors may leak or experience performance degradation during continuous lifting and tilting operations, requiring replacement.

4. Harvesters: Hydraulic cylinders in harvesters’ hydraulic systems sustain high pressure during harvesting, and cylinder fatigue may occur, necessitating timely replacement to maintain work efficiency.

5. Automated Production Lines: Hydraulic cylinders control robotic arms and other automated equipment. Cylinder faults can affect production efficiency, requiring immediate replacement.

Maintenance:

To ensure the Replacement Of AW14971 Fork Hydraulic Cylinder’s longevity, regular maintenance is necessary. Here are three common maintenance tasks:

1. Regular Inspection: Regular inspection of the hydraulic cylinder to check for leaks, corrosion, and wear can prevent further damage to the machine.

2. Proper Lubrication: Correct lubrication of the hydraulic cylinder with adequate hydraulic oil can reduce wear and tear of the cylinder and extend its life span.

3. Seal Replacement and Calibration Checks: Replacement of seals and calibration checks can ensure proper hydraulic cylinder operation.

Safety Considerations:

When using the Replacement Of AW14971 Fork Hydraulic Cylinder, certain safety precautions must be undertaken. Proper use of personal protective equipment, such as gloves and safety glasses, is necessary. It is also essential to follow the machine’s instructions and never exceed the hydraulic cylinder’s maximum operating pressure.

Troubleshooting and Diagnosis:

The hydraulic cylinder may develop issues that require troubleshooting. Here are some common problems and their solutions:

1. Leaks: Inspect the cylinder seals, replace them, and check the hydraulic fluid level.

2. Slow Operation: Check for low hydraulic fluid levels or a damaged piston seal.

3. Noisy Operation: Check for worn hydraulic cylinder components or low hydraulic fluid levels.

Preventive Measures:

To prevent hydraulic cylinder problems, regular inspection and maintenance are critical. Also, it is essential to follow the machine’s instructions for the proper use and operation of the hydraulic cylinder.

Product Design Considerations:

The Replacement Of AW14971 Fork Hydraulic Cylinder’s design considerations include load-bearing capacity, sealing, durability, safety, and maintainability. Here is a breakdown of the design considerations:

1. Load-bearing Capacity: The hydraulic cylinder’s design must be able to handle the machine’s maximum load capacity.

2. Sealing: The hydraulic cylinder’s seals must be durable and wear-resistant to prevent fluid leakage.

3. Durability: The hydraulic cylinder’s components must be able to withstand extreme operating conditions and be made of materials that are resistant to corrosion and wear.

4. Safety: The hydraulic cylinder must be designed with safety in mind and must not exceed the maximum operating pressure.

5. Maintainability: The hydraulic cylinder must be easy to maintain and replace when necessary.

Sealing and Lubrication:

To ensure the hydraulic cylinder’s longevity, it is essential to use proper sealing and lubrication. High-quality seals made of materials such as polyurethane and nitrile rubber can extend the hydraulic cylinder’s life. Lubrication with adequate hydraulic oil is also critical to reduce wear and tear of the cylinder.

Installation Guide:

When installing the Replacement Of AW14971 Fork Hydraulic Cylinder, it is essential to align the cylinder to the machine’s specifications. The use of proper installation brackets to secure the cylinder is also recommended. Follow the recommended inspection, repair, and replacement procedures to maintain the hydraulic cylinder’s longevity.

Company Information:

We are a leading manufacturer and wholesaler of hydraulic cylinders, offering a wide range of products to domestic and international markets. Our company offers professional, customized services, and our production equipment is state-of-the-art. We also offer after-sales services to ensure customer satisfaction.

Conclusion:

The Replacement Of AW14971 Fork Hydraulic Cylinder is an essential component in industrial machines. Regular inspection, proper lubrication, seal replacement, and calibration checks are critical to maintaining the hydraulic cylinder’s longevity. Safety precautions should also be taken when using the hydraulic cylinder. Troubleshooting and diagnosis of common problems can help prevent future hydraulic cylinder issues. Proper installation and maintenance are necessary to optimize the hydraulic cylinder’s performance. Our company offers high-standard hydraulic cylinders with excellent customer service.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: