Replacement Of N222897 Hydraulic Cylinder End

Як один з виробників, постачальників та експортерів механічних виробів, ми пропонуємо гідравлічні циліндри та багато інших продуктів.

Будь ласка, зв'яжіться з нами для уточнення деталей.

Пошта:sales@hydraulic-cylinders.net

Виробник, постачальник, експортер гідравлічних циліндрів.

Replacement Of N222897 Hydraulic Cylinder End

Introduction:

The Replacement Of N222897 Hydraulic Cylinder End is a vital component used in various industrial applications. This hydraulic cylinder plays a crucial role in providing the necessary force and motion for the efficient operation of machinery. It is designed to withstand heavy loads and ensures smooth and precise movement.

Specifications:

- Weight: 5.11 lb

- Height: 1.5 in

- Width: 2 in

- Length: 7.25 in

- Screw Size: 1.125 in

Model: 748 7460

Features:

- Improved Equipment Performance: Replacing damaged or worn-out hydraulic cylinders can restore the normal operational capability of the equipment, ensuring optimal performance in various applications.

- Enhanced Safety: Regular replacement of hydraulic cylinders reduces the safety risks associated with cylinder failures, ensuring the safety of both operators and equipment.

- Overload Protection: New cylinder designs often incorporate better overload protection mechanisms, enhancing overall safety.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts in the market.

We specialize in producing and offering perfect replacements for these hydraulic cylinders. Our products are designed to seamlessly replace the original cylinders while meeting or exceeding the required specifications.

Applications:

Here are three examples of how the Replacement Of N222897 Hydraulic Cylinder End is used:

- Excavators: The hydraulic cylinder on the arm or bucket of an excavator may get damaged due to prolonged use or overloading, requiring replacement to restore normal operation.

- Cranes: The hydraulic cylinder on the crane’s lifting boom is prone to wear during frequent lifting and lowering processes, necessitating regular replacement for safety purposes.

- Tractors: The hydraulic cylinder on the front loader of a tractor may develop leaks or experience performance degradation due to continuous lifting and tilting operations, demanding replacement.

These are just a few examples of the diverse applications where the Replacement Of N222897 Hydraulic Cylinder End proves essential. Its reliable performance ensures the smooth operation of various equipment, including harvesting machines, automated production lines, bulldozers, and mining equipment.

Maintenance Tasks:

Regular maintenance is crucial for ensuring the longevity and optimal performance of the Replacement Of N222897 Hydraulic Cylinder End. Here are three common maintenance tasks:

- Regular Inspections: Periodically inspect the cylinder for any signs of damage, leaks, or abnormal wear. Address any issues promptly to prevent further damage.

- Proper Lubrication: Adequate lubrication is essential to minimize friction and extend the lifespan of the cylinder. Follow the recommended lubrication guidelines for optimal performance.

- Seal Replacement and Calibration Checks: Replace worn-out seals to maintain proper sealing integrity. Periodically calibrate the cylinder to ensure accurate operation.

During installation, it is important to provide guidance on aligning the cylinder correctly. Using suitable installation brackets to secure the cylinder is recommended. We offer inspection, repair, and replacement services, along with valuable tips to enhance the lifespan of the Replacement Of N222897 Hydraulic Cylinder End.

Safety Considerations and Environmental Factors:

When using hydraulic cylinders, adhering to safety measures is of utmost importance. Proper training and following safety protocols minimize the risk of accidents and ensure a safe working environment. Environmental factors should also be considered, and appropriate precautions should be taken to prevent contamination and optimize the cylinder’s performance.

Fault Diagnosis and Common Issues:

Here are some common faults and issues that may arise with hydraulic cylinders:

- Leakage: Leaking hydraulic fluid indicates a damaged seal or other component. Promptly identify and replace the faulty part.

- Slow or Inconsistent Movement: If the cylinder’s movement becomes sluggish or irregular, it may be due to insufficient lubrication, worn-out components, or improper alignment.

- Overheating: Excessive heat can lead to cylinder failure. Check for proper fluid levels, ensure adequate cooling, and address any blockages or restrictions in the system.

To diagnose and resolve these problems effectively, consider the following tips:

- Perform regular inspections and maintenance checks to identify issues early.

- Consult the manufacturer’s guidelines and technical resources for troubleshooting assistance.

- Implement preventive measures to minimize potential problems, such as proper lubrication and seal replacements.

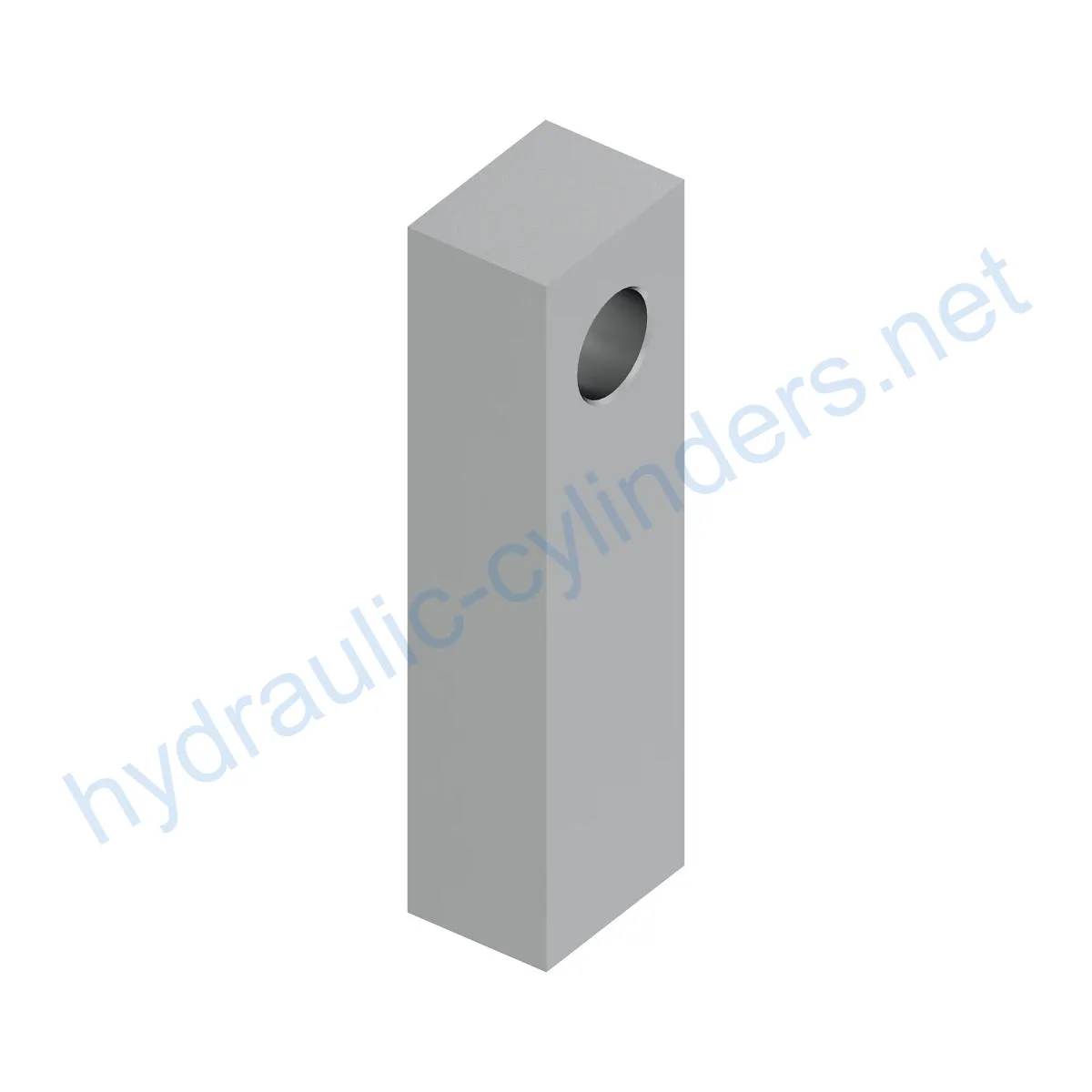

Attached is an image of the Replacement Of N222897 Hydraulic Cylinder End:

Design Considerations and Selection Criteria:

When considering the design and selection of hydraulic cylinders, several factors are essential:

- Load-bearing Capacity: Ensure the selected cylinder can handle the required load without compromising performance or safety.

- Sealing and Durability: Opt for seals made from wear-resistant materials like polyurethane or nitrile rubber. Finely treated cylinder body and threaded ends enhance durability.

- Safety and Maintenance: Choose cylinders designed with safety features and ease of maintenance in mind.

Sealing and Lubrication:

Proper sealing and lubrication are crucial for the optimal performance of hydraulic cylinders. Consider the following recommendations:

- Utilize various sealing components, such as piston seals and rod seals, made from durable materials to minimize wear.

- Treat the cylinder body and threaded ends to improve wear resistance.

- Regularly add the appropriate amount of hydraulic fluid for lubrication.

Regular Inspections and Preventive Maintenance:

Regular inspections and preventive maintenance are essential to prolong the lifespan of the Replacement Of N222897 Hydraulic Cylinder End. Here are some recommended measures:

- Proper installation, lubrication, and adjustment are vital for the cylinder’s performance and longevity.

- Provide guidance on aligning the cylinder correctly during the installation process.

- Suggest the use of suitable installation brackets to secure the cylinder in place.

- Recommend inspection, repair, and replacement procedures to address any potential issues promptly.

- Offer replacement parts and rebuilding services to enhance the lifespan of the hydraulic cylinder.

- Provide tips and techniques to improve the overall durability and performance of the cylinder.

Attached is an image of the Replacement Of N222897 Hydraulic Cylinder End:

About Our Company

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: