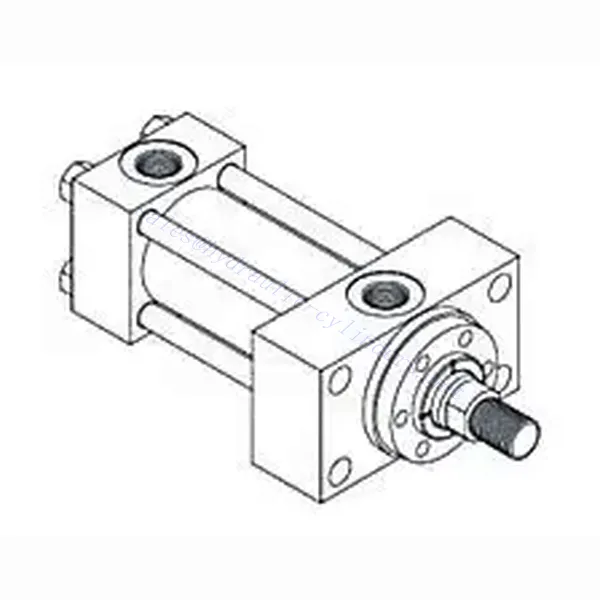

前盖矩形法兰四连杆液压缸

前盖矩形法兰四连杆液压缸

The front cover rectangular flange four-bar hydraulic cylinder is a cutting-edge assembly that offers superior performance in various industrial applications. With its innovative design, precise engineering, and robust construction, this hydraulic cylinder provides excellent functionality and reliability. This paper will discuss the main features, use methods, and maintenance guidelines of the front cover rectangular flange four rod hydraulic cylinder.

Essential Characteristics Of Four Rod Hydraulic Cylinder:

The front cover rectangular flange four rod hydraulic cylinder boasts several remarkable features that make it a standout product in the hydraulic industry:

Enhanced Stability and Load-Bearing Capacity:

- The unique rectangular flange design provides superior stability on the cylinder by evenly distributing the load. This design minimizes deflection and ensures consistent performance even under heavy loads and challenging operating conditions.

- The increased load-bearing capacity allows the cylinders to handle large loads and high forces, making them ideal for demanding industrial applications.

Precise Control and Positioning:

- The cylinder’s four rod configuration allows precise control and positioning of the piston rod. This feature ensures accurate movement and alignment of loads for detailed and synchronized operations.

- The precise control provided by the cylinder makes it ideal for applications that require precise motion control, such as robotics, material handling, and automation systems.

Durability and Longevity:

- Front cover rectangular flange four rod hydraulic cylinder can withstand harsh environments and heavy use. It is made of high quality materials that provide superior strength, durability, wear resistance, and corrosion resistance.

- The four rod hydraulic cylinder’s rugged construction ensures longevity and reliable performance, reducing downtime and maintenance costs.

Front Cover Rectangular Flange Four Rod Hydraulic Cylinder Parameter:

前盖矩形法兰四连杆液压缸:

The front cover rectangular flange four rod hydraulic cylinder is designed for straightforward integration into various hydraulic systems. Here’s a general guide to using the cylinder effectively:

Mounting and Connection:

- Ensure proper alignment and secure cylinder mounting to the equipment or machinery using suitable bolts or fasteners.

- Connect the hydraulic lines to the four rod hydraulic cylinder’s inlet and outlet ports, ensuring a secure and leak-free connection. Use appropriate fittings, seals, and thread types as the manufacturer recommends.

Hydraulic Control:

- Activate the hydraulic system that powers the cylinder by operating the associated hydraulic pump or control valve.

- Control the four rod hydraulic cylinder’s movement by adjusting the hydraulic flow and pressure using the control valve. This allows for precise positioning and operation of the hydraulic cylinder.

Maintenance Of TD Front Cover Rectangular Flange Four Rod Hydraulic Cylinder:

Proper maintenance of the front cover rectangular flange four rod hydraulic cylinder is vital to ensure optimal performance and extend its lifespan. Consider the following maintenance tips:

- 定期检查:

- Periodically inspect the cylinder for any leakage, damage, or excessive wear. Pay attention to seals, rods, and mounting components.

- Replace any worn or damaged parts promptly to prevent further issues and ensure optimal performance.

- 润滑:

- Follow the manufacturer’s recommendations for lubrication intervals. Apply high-quality hydraulic oil or grease to the rod, seals, and other moving parts.

- Proper lubrication minimizes friction, reduces wear, and ensures smooth operation of the hydraulic cylinder.

- Cleanliness:

- Keep the cylinder and its surroundings clean and free from dirt, debris, or contaminants affecting performance.

- Regularly remove accumulated dirt or grime using a mild cleaning agent and a soft cloth.

How To Disassemble A Hydraulic Cylinder?

Disassembling a hydraulic cylinder requires careful attention and adherence to proper procedures to ensure safe and effective disassembly. Here is a step-by-step guide on how to disassemble a hydraulic cylinder:

- Preparation and Safety:

- Ensure you have a clean, organized workspace with ample room to work on the hydraulic cylinder.

- Wear appropriate personal protective equipment, including safety glasses, gloves, and protective clothing, to protect yourself from hazards.

- Release Hydraulic Pressure:

- Before disassembling the hydraulic cylinder, release the pressure to avoid sudden movements or accidental activation.

- Open the hydraulic control valve or release the pressure using the appropriate method recommended by the manufacturer.

- Remove External Components:

- Begin by removing external components, such as mounting brackets, clevis pins, or bolts that secure the cylinder to the equipment or machinery.

- Carefully set aside these components in a safe place for reassembly later.

- Remove the Cylinder Cap:

- Locate the cylinder cap, typically at one end of the cylinder.

- Use the appropriate tools, such as wrenches or socket sets, to loosen and remove the bolts or fasteners that secure the cylinder cap.

- Tap the cap to loosen it and carefully remove it from the cylinder.

- Extract the Piston Assembly:

- With the cylinder cap removed, you can access the piston assembly.

- Carefully slide out the piston assembly from the cylinder barrel. It may be necessary to apply gentle pressure or tap the assembly to loosen it.

- Do not damage the piston seals or other components as you remove the assembly.

- Remove the Piston Rod:

- After removing the piston assembly, you can now extract the piston rod.

- Slide the piston rod out of the cylinder barrel, not damaging it or the rod seals.

- If there are any retaining devices or attachments, such as snap rings or bolts, remove them first before attempting to remove the rod.

- Disassemble Additional Components:

- Depending on the hydraulic cylinder’s design, additional components may need to be disassembled.

- Follow the manufacturer’s instructions or guidelines to disassemble any remaining components, such as the gland assembly or rod seals.

- Inspection and Cleaning:

- Inspect all disassembled components for signs of wear, damage, or contamination. Pay special attention to seals, rods, and cylinder walls.

- Clean the components using an appropriate cleaning solution to remove debris, dirt, or old lubricants. Use lint-free cloths or compressed air to dry the components completely.

- Replacement or Repair:

- If any components show signs of wear or damage, replace them with new ones from a reputable supplier.

- If necessary, repair or refurbish components as the manufacturer or a qualified professional recommends.

- Reassembly:

- Begin reassembling the hydraulic cylinder by following the reverse order of disassembly.

- Lubricate the seals and other moving parts with a compatible hydraulic fluid or assembly lubricant to aid reassembly and ensure proper functioning.

- Ensure all components are properly aligned and fitted together.

- Tighten all bolts or fasteners to the manufacturer’s recommended torque specifications, ensuring a secure assembly.

- Testing and Reinstallation:

- Once the hydraulic cylinder is reassembled, conduct a thorough inspection to ensure all components are properly aligned and fitted together.

- Reinstall the hydraulic cylinder into the equipment or machinery, following any specific instructions provided by the manufacturer.

- Reconnect the hydraulic lines, ensuring all connections are secure and leak-free.

- Test the hydraulic cylinder for proper function and operation, checking for any leaks, abnormal noises, or other issues during operation.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best light four rod hydraulic cylinder manufacturers. We can offer comprehensive light four rod hydraulic cylinder stock. We also provide corresponding 农用齿轮箱.我们的产品已出口到世界各地,并凭借卓越的产品质量和售后服务赢得了良好的声誉。我们热忱欢迎海内外客户与我们联系,洽谈业务,交流信息,共谋发展。 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

液压缸应用: