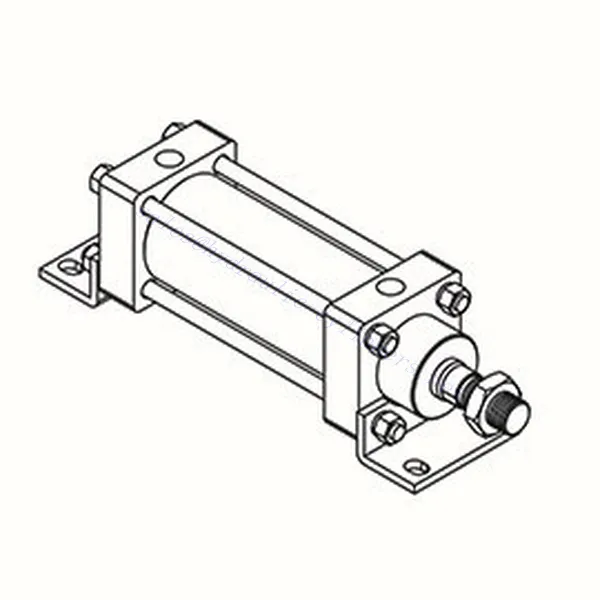

LB 脚架式光杆液压缸

LB 脚架式光杆液压缸

The LB footstand type light rod hydraulic cylinder is a high-performance hydraulic element that provides precise and efficient linear motion control in various industrial applications. With its unique pedal design and lightweight construction, this light rod hydraulic cylinder offers versatility, durability, and superior performance.

Critical Features Of Light Rod Hydraulic Cylinder:

Tripod Design: LB light rod hydraulic cylinders have a tripod that provides stability and ease of installation. The tripod ensures safe installation and improves cylinder compatibility with different systems and equipment.

轻质结构: This light rod hydraulic cylinder provides superior strength while minimizing weight using lightweight materials such as aluminum and advanced composite materials. The lightweight design is easy to operate and contributes to overall system efficiency.

Light Rod Technology: Cylinders use lightweight rod technology to optimize their performance by reducing weight without compromising strength and durability. This innovative design ensures smooth and precise linear motion control.

Versatile Applications: LB light rod cylinders are suitable for various industrial applications, including automation, robotics, material handling systems, etc. Its versatility makes it stand out in multiple industries and meet different motion control needs.

LB Footstand Type Light Rod Hydraulic Cylinder Parameter:

LB 脚架式光杆液压缸 Usage Method:

Installation: First, choose a suitable installation location. Tripod design simplifies installation and provides stability and ease of placement. Use recommended bolts to secure the cylinder and ensure proper alignment.

Hydraulic connection: Connect the hydraulic hose to the cylinder to ensure a tight connection without leakage. During installation, follow the manufacturer’s torque specification guidelines to maintain the integrity of the hydraulic system.

System integration: The cylinder is integrated into the hydraulic system and aligned with other components according to system requirements. Refer to the manufacturer’s guidelines and system schematics for proper installation.

Operation: Hydraulic pressure is applied to the system while adhering to industry standard safety protocols. With their pedal design, LB light rod hydraulic cylinders effectively convert fluid pressure into precise linear motion, providing optimal control for various applications.

LB 脚架式光杆液压缸 Maintenance:

Regular maintenance is crucial to ensure the longevity and optimal performance of the LB Footstand Cylinder. Consider the following maintenance guidelines:

- Visual inspection: Periodically check the cylinder for signs of leakage, damage, or wear. Pay close attention to the overall condition of seals, bearings, and cylinders. Replace worn or damaged parts promptly.

- Lubrication: Follow the manufacturer’s recommended lubrication intervals and use appropriate lubricants. Proper lubrication minimizes friction, reduces wear, and ensures smooth operation.

- Cleaning: Clean the cylinder by removing dirt, debris, and contaminants. Use a non-abrasive cleaning agent and not use too much force during cleaning to avoid damaging vital components.

- Seal inspection: Check the seal regularly for leakage or deterioration. Replace worn or damaged seals to maintain optimal performance and prevent potential system failures.

- System calibration: Periodically check cylinder performance by verifying stroke length, speed, and accuracy. The system is calibrated as necessary to ensure accurate and consistent operation.

How To Repair A Hydraulic Cylinder?

Repairing a hydraulic cylinder requires careful attention and knowledge of the cylinder’s components and hydraulic systems. Here is a general guide on how to fix a hydraulic cylinder:

- 安全第一: Before beginning any repair work, ensure the hydraulic system is depressurized and the equipment is safely secured to prevent accidental movement or injury.

- Identify the Issue: Determine the specific problem with the hydraulic cylinder. Typical issues may include leaking seals, damaged rods, bent tubes, or worn-out components.

- 拆卸: Carefully disassemble the hydraulic cylinder, following the manufacturer’s instructions or guidelines. Take note of the order of removed components for proper reassembly.

- 检查: Thoroughly inspect all components for signs of damage, wear, or malfunction. Pay close attention to seals, rods, pistons, and cylinder barrels. Replace any parts that are worn, damaged, or leaking.

- Seal Replacement: If the cylinder leaks, replace the seals with new, manufacturer-approved seals. Ensure proper installation and lubrication of the seals.

- Rod Repair or Replacement: If the piston rod is damaged or bent, it may need to be repaired or replaced. Minor surface damage can often be repaired by grinding or polishing. However, more severe damage may require rod replacement.

- Barrel Repair or Replacement: If the cylinder barrel is damaged or worn, it may need to be repaired or replaced. Consult with a professional or the manufacturer to determine the best action.

- 清洁: Thoroughly clean all components, removing any dirt, debris, or contaminants that could interfere with the cylinder’s operation.

- 重新组装: Carefully reassemble the hydraulic cylinder, ensuring all components are correctly aligned and tightened according to the manufacturer’s specifications. Use the appropriate torque settings for fasteners.

- Testing and Inspection: Test its operation once the hydraulic cylinder is reassembled. Check for smooth movement, proper sealing, and any signs of leakage. Monitor the cylinder’s performance during initial use to ensure that the repair was successful.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

我们是最好的光杆液压缸制造商之一。我们可以提供广泛的光杆液压缸库存。我们还提供相应的 农用齿轮箱.我们的产品已出口到世界各地,并凭借卓越的产品质量和售后服务赢得了良好的声誉。我们热忱欢迎海内外客户与我们联系,洽谈业务,交流信息,共谋发展。 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

液压缸应用: