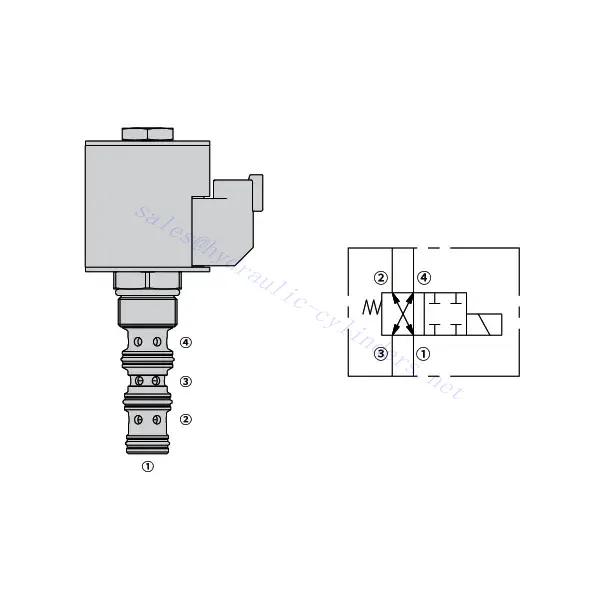

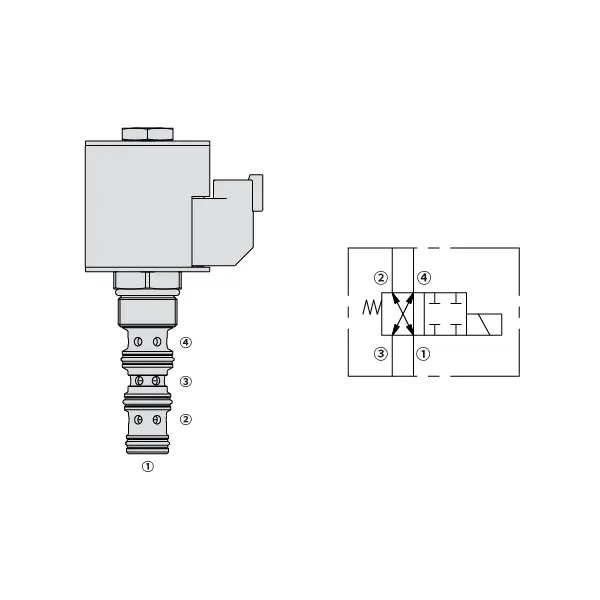

30SD10-42 Solenoid Directional Valve

30SD10-42 Solenoid Directional Valve

The 30SD10-42 solenoid directional valve is a cutting-edge hydraulic component that offers unmatched efficiency and control in various applications. Designed with precision engineering and advanced technology, this valve ensures seamless directional control of hydraulic fluid, allowing for precise and reliable operation in various industries. From industrial machinery to mobile equipment, the 30SD10-42 solenoid directional valve is a trusted solution for optimizing hydraulic systems.

The 30SD10-42 solenoid directional valve is a game-changer for hydraulic systems, providing unparalleled efficiency, control, and reliability. By following the proper usage and maintenance guidelines, you can optimize the performance and longevity of this valve. Invest in the 30SD10-42 solenoid directional valve today and experience the benefits of enhanced precision and efficiency in your hydraulic systems.

30SD10-42 Solenoid Directional Valve Characteristics:

- Precision Control: With its advanced design and technology, the valve ensures precise and reliable directional control of hydraulic fluid, allowing for smooth and efficient operation.

- Durability: Built with high-quality materials and subjected to rigorous testing, the valve is designed to withstand demanding environments and provide long-lasting performance.

- Versatility: The valve’s versatile design suits various applications across industries, including industrial machinery and mobile equipment.

- Efficient Flow Control: The valve’s optimized flow path minimizes pressure drop, enhancing the hydraulic system’s efficiency.

- Safety Features: The valve incorporates safety mechanisms such as pressure relief and overload protection, ensuring the security of equipment and personnel during operation.

30SD10-42 Solenoid Directional Valve Parameter:

| Rated pressure | 207 bar(3000 psi) | |

| Peak flow | See performance chart | |

| Fluid | Mineral-based or synthetics with lubricating properties | |

| Fluid temperature range ℃ | -54 to 107 ℃ (Polyurethane seals) | |

| -40 to 100 ℃ (Buna N seals) | ||

| -26 to 204 ℃ (Fluorocarbon seals) | ||

| Viscosity range | 7.4 to 420 mm2/s | |

| Degree of contamination | The minimum pollution level is ISO4406 level 20/18/14, and level 17/15/13 is recommended to prolong the service life | |

| Internal Leakage | ≤ 82 mL/min@207bar | |

| Cavity | VC10-4 | |

| Coil Duty Rating | Continuous from 85% to 115% of nominal voltage | |

| Initial Coil Current Draw at 20℃ | E-coil | 1.7A at 12VDC; 0.85A at 24VDC |

| D-coil | 1.67A at 12VDC; 0.83A at 24VDC | |

| Minimum pull-in voltage | 85% of nominal at 207 bar | |

30SD10-42 Solenoid Directional Valve Advantages:

• Continuous-duty rated coil

• Cartridges are voltage interchangeable

• Optional waterproof E-Coils rated up to IP69K

• Efficient wet-armature construction

• Industry common cavity

• Hardened parts for long life

Usage Method Of 30SD10-42 Solenoid Directional Valve:

- Installation: Begin by ensuring that your hydraulic system is powered off and depressurized. Identify the appropriate location for the valve and securely mount it using the recommended mounting techniques, ensuring proper alignment.

- Connection: Connect the hydraulic lines to the designated inlet and outlet ports of the valve. Ensure that all connections are tight, leak-free, and properly sealed to prevent fluid loss.

- Electrical Wiring: Wire the solenoid valve to the control system using the specified electrical connections. Follow the manufacturer’s instructions to ensure proper voltage, polarity, and grounding.

- System Calibration: Power on the hydraulic system and activate the control mechanism. Adjust the control settings to calibrate the valve’s performance according to your specific application requirements.

- Operation: Engage the control mechanism to activate the 30SD10-42 Solenoid Directional Valve. Experience the precision and efficiency as the valve directs hydraulic fluid flow, enabling seamless operation of your machinery or equipment.

How To Identify Delta Shower Valve Cartridge?

Identifying a Delta shower valve cartridge can be essential when it comes to troubleshooting or replacing a faulty cartridge in your Delta shower system. Here are the steps to help you identify the Delta shower valve cartridge:

- Turn off the Water: Before starting any work on your shower, make sure to turn off the water supply to the shower. You can typically find the shut-off valve near the shower or in the main water supply line of your house.

- Remove the Handle: Depending on the type of Delta shower faucet you have, the handle removal method may vary. Most Delta shower handles have a small cap covering the screw that holds the handle in place. Use a flathead screwdriver to pry off the cap. Once the screw is exposed, use a screwdriver to remove it and gently pull off the handle.

- Remove the Trim Plate: After removing the handle, you’ll find a trim plate or escutcheon surrounding the valve. This plate is usually secured with screws or is a threaded piece that can be unscrewed. Use a screwdriver or pliers to remove the screws or twist the trim plate counterclockwise to remove it.

- Identify the Cartridge: With the trim plate removed, you will now have access to the cartridge. The cartridge is a cylindrical component that controls the flow and temperature of the water. Delta shower cartridges come in different types, so it’s important to identify the specific cartridge you have.

- Single-Handle Cartridge: If you have a single-handle Delta shower faucet, the cartridge will usually be a single unit with a round or hexagonal top. It may also have a colored cap, such as blue or red, indicating hot or cold water.

- Dual-Handle Cartridge: For dual-handle Delta shower faucets, you will have two separate cartridges—one for hot water and one for cold water. These cartridges typically have a stem with a square or hexagonal top.

- Note the Cartridge Model: Once you have identified the cartridge, take note of its model number or series. This information is usually imprinted on the side of the cartridge or can be found in the documentation that came with your Delta shower system.

- Replace or Troubleshoot: If you need to replace the cartridge, having the model number or series will help you find the exact replacement cartridge. You can visit a local plumbing supply store or contact Delta customer service for assistance. If you’re experiencing specific issues with your shower, such as leaks or temperature control problems, knowing the cartridge model will also aid in troubleshooting the problem.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

液压缸应用: