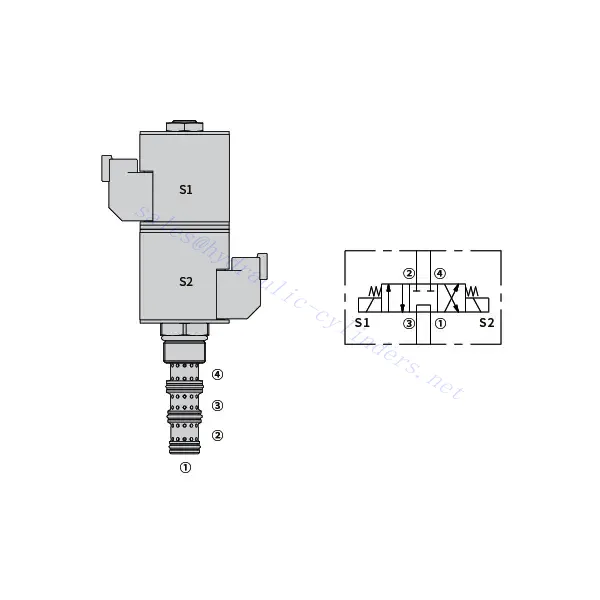

35SD10-47A Solenoid Directional Valve

The 35SD10-47A solenoid directional valve is a high-performance hydraulic component designed to provide exceptional efficiency and precise control in various applications. With advanced engineering and cutting-edge technology, this valve allows for seamless directional control of hydraulic fluid, enabling reliable operation in various industries. From industrial machinery to mobile equipment, the 35SD10-47A solenoid directional valve is the trusted solution for optimizing hydraulic systems.

The 35SD10-47A solenoid directional valve offers exceptional hydraulic systems efficiency, control, and durability. Its precise directional control capabilities, robust construction, and easy installation make it an excellent choice for various applications. By following the recommended maintenance practices, you can ensure optimal performance and extend the lifespan of this valve. Invest in the 35SD10-47A solenoid directional valve today and experience enhanced efficiency and control in your hydraulic systems.

35SD10-47A Solenoid Directional Valve Characteristics:

- Robust Construction: The 35SD10-47A solenoid directional valve is built to withstand demanding environments. Constructed from high-quality materials, it offers exceptional durability and longevity, ensuring reliable performance even in harsh conditions.

- High Flow Capacity: This valve boasts a high flow capacity, enabling efficient and rapid movement of hydraulic fluid. It facilitates quick response times and enhances the overall productivity of hydraulic systems.

- Precise Control: The 35SD10-47A solenoid directional valve allows precise control over the direction of hydraulic flow. It offers excellent accuracy and repeatability, ensuring your hydraulic system operates strictly as intended.

- Low Pressure Drop: With its optimized design, this valve minimizes pressure drop, maximizing the efficiency of your hydraulic system. It allows for smooth fluid flow without unnecessary energy losses.

35SD10-47A Solenoid Directional Valve Parameter:

| Rated pressure | 240 bar (3500 psi) | |

| Peak flow | 19 L/min (5 gpm) | |

| Fluid | Mineral-based or synthetics with lubricating properties | |

| Fluid temperature range ℃ | -54 to 107 ℃ (Polyurethane seals) | |

| -40 to 100 ℃ (Buna N seals) | ||

| -26 to 204 ℃ (Fluorocarbon seals) | ||

| Viscosity range | 7.4 to 420 mm2/s | |

| Degree of contamination | The minimum pollution level is ISO4406 level 18/16/13, and level 15/13/11 is recommended to prolong the service life | |

| Internal Leakage | ≤ 328 mL/min@240 bar | |

| Cavity | VC10-4 | |

| Coil Duty Rating | Continuous from 85% to 115% of nominal voltage | |

| Initial Coil Current Draw at 20℃ | E-coil | 1.7A at 12VDC; 0.85A at 24VDC |

| D-coil | 1.67A at 12VDC; 0.83A at 24VDC | |

| Minimum pull-in voltage | 85% of nominal at 207 bar | |

35SD10-47A Solenoid Directional Valve Advantages:

• Continuous-duty rated coil

• Cartridges are voltage interchangeable

• Optional waterproof E-Coils rated up to IP69K

• Efficient wet-armature construction

• Industry common cavity

• Hardened parts for long life

Maintenance Of 35SD10-47A Solenoid Directional Valve:

Using the 35SD10-47A Solenoid Directional Valve is straightforward and user-friendly. Here’s a step-by-step guide to get you started:

- System Preparation: Ensure the hydraulic system is appropriately set up and all necessary components are in place.

- Mounting: Install the 35SD10-47A solenoid directional valve in the desired location within the hydraulic system and secure it tightly using appropriate mounting brackets or fasteners.

- Plumbing Connections: Connect the hydraulic lines to the designated ports on the valve. Ensure proper alignment and tighten the connections to prevent any leaks.

- Electrical Connections: Connect the solenoid valve to the electrical power supply. Follow the wiring diagram provided with the valve to connect the wires and ensure safe operation correctly.

- Test and Adjust: Once the valve is installed and connected, test its functionality by activating the solenoid and observing the directional control of the hydraulic fluid. Make any necessary adjustments to ensure proper operation.

How To Remove A Moen Shower Valve Cartridge?

Removing a Moen shower valve cartridge is a crucial step when replacing or repairing your shower valve. Here’s a step-by-step guide to help you remove the cartridge:

- Gather the Required Tools: Before starting, gather the necessary tools, including an adjustable wrench, pliers, a cartridge puller (if needed), and a screwdriver.

- Turn Off the Water Supply: Locate the main water shut-off valve for your house and turn it off to stop the water flow to the shower. If you have a dedicated shut-off valve for the shower, you can use that instead.

- Remove the Handle and Trim: Remove the handle by locating the set screw or screw cover on the handle and using a screwdriver or Allen wrench to loosen and remove it. Once the screw is removed, pull the handle off. Next, remove the trim plate or escutcheon surrounding the valve using a screwdriver.

- Identify the Retaining Clip: Behind the trim plate, you will find a retaining clip or pin that holds the cartridge in place. This clip might be circular or horseshoe-shaped, depending on the Moen shower valve model.

- Remove the Retaining Clip: Use pliers to grip the retaining clip and carefully pull it out. Be cautious as the clip may spring out when released. Set the clip aside for reinstallation later.

- Extract the Cartridge: With the retaining clip removed, the cartridge is ready to be taken out. Grasp the cartridge firmly with pliers or use a cartridge puller if necessary. Slowly and steadily pull the cartridge straight out of the valve body.

- Clean and Inspect: Once the cartridge is removed, inspect it for any signs of damage or wear. Also, take a moment to clean the valve body and remove any debris or buildup that may affect the new cartridge’s performance.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!