Aerial Work Platform Luffing Cylinder

Aerial Work Platform Luffing Cylinder

The aerial work platform luffing cylinder is a vital component in aerial work platforms, designed to enhance safety and efficiency in elevated work environments. This innovative hydraulic cylinder provides controlled vertical movement, allowing for precise lifting and lowering of the platform.

The aerial work platform luffing cylinder is a crucial component in aerial work platforms, providing controlled vertical movement and enhancing safety and efficiency in elevated work environments. With its precise lifting capabilities, high load capacity, and integrated safety features, this cylinder empowers operators to work at different heights confidently. By following the recommended usage methods and maintenance practices, operators can maximize the lifespan and performance of the aerial work platform luffing cylinder, resulting in increased productivity, reduced downtime, and enhanced safety in elevated work applications. Invest in this advanced hydraulic component to elevate your aerial work platform’s capabilities and take your eloquent work to new heights of success.

Aerial Work Platform Luffing Cylinder Key Characteristics:

- Controlled Vertical Movement:

- The aerial work platform luffing cylinder offers precise and controlled vertical movement, enabling operators to adjust the working height of the platform with accuracy and ease.

- It provides smooth and stable lifting and lowering actions, ensuring a secure and comfortable working environment at different heights.

- High Load Capacity:

- This cylinder boasts a high load capacity, allowing it to support heavy loads and accommodate multiple workers, tools, and equipment on the aerial work platform.

- It provides reliable lifting performance, maintaining stability and safety even with substantial payloads.

- Compact and Robust Design:

- The aerial work platform luffing cylinder features a compact design, minimizing the overall weight and footprint of the aerial work platform.

- Its robust construction ensures durability and longevity, withstanding the demanding conditions of elevated work environments.

- Integrated Safety Features:

- This cylinder has integrated safety features like overload protection and emergency lowering systems.

- These safety mechanisms provide additional peace of mind, safeguarding against potential accidents and facilitating a quick response during emergencies.

Aerial Work Platform Luffing Cylinder Parameter:

| Product Name | Aerial Work Platform Luffing Cylinder |

| Features: | Realizing the up-and-down pitching rotation of the boom is the main driving force for lifting |

| Bore diameter: | 50mm~350mm |

| Rod diameter: | 30mm~300mm Stroke≤3000 mm |

| Pressure: | 30MPa(Maximum pressure) |

| Luffing Cylinder Applications: | Aerial Work Platform |

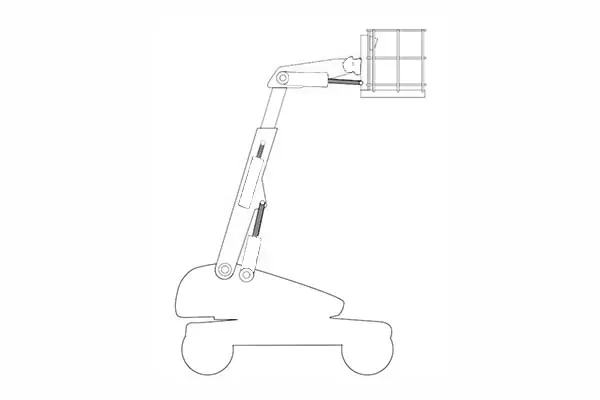

Aerial Work Platform Identification Diagram:

使用方法 Aerial Work Platform Luffing Cylinder:

- Cylinder Installation:

- Follow the manufacturer’s instructions for properly installing the aerial work platform luffing cylinder.

- Ensure the cylinder is securely mounted to the aerial work platform’s structure, providing a stable and reliable connection.

- Hydraulic Connection:

- Connect the cylinder to the hydraulic system of the aerial work platform according to the provided guidelines.

- Ensure that all hydraulic connections are secure and properly sealed to prevent any leaks or loss of hydraulic fluid.

- Control Activation:

- Utilize the platform’s control panel or interface to activate the aerial work platform luffing cylinder.

- Follow the recommended operating procedures to lift or lower the platform to the desired height.

- Safety Precautions:

- Before operating the aerial work platform, familiarize yourself with the safety features and emergency procedures.

- Ensure that all operators receive proper training on the safe operation of the platform and the aerial work platform luffing cylinder.

How To Get Water Out Of Tractor Hydraulic System?

Getting water out of a tractor’s hydraulic system is essential to maintain the system’s performance and prevent damage. Here’s a step-by-step guide on how to remove water from a tractor hydraulic system:

- Identify the Water Contamination:

- Check for signs of water contamination, such as milky or cloudy hydraulic fluid, reduced system performance, or water droplets in the reservoir.

- Confirm that water is the cause of the issue by ruling out other potential problems.

- Drain the Hydraulic System:

- Locate the drain plug or valve on the hydraulic reservoir or tank.

- Place a suitable container or drain pan beneath the drain plug to catch the fluid.

- Open the Drain Plug:

- Carefully loosen and remove the drain plug or open the valve using an appropriate wrench or tool.

- Allow the contaminated hydraulic fluid to drain completely from the system.

- Dispose of the contaminated fluid according to local regulations.

- Flush the System:

- Once the hydraulic fluid is drained, flush the system with a suitable flushing agent or clean hydraulic fluid.

- Follow the manufacturer’s recommendations for the appropriate flushing agent and procedure.

- Connect a hose to the hydraulic system’s inlet and use it to pump the flushing agent or clean fluid through the system.

- Let the flushing agent circulate through the system sufficiently to dislodge any remaining water.

- Drain the Flushing Agent:

- Open the drain plug or valve again to drain the flushing agent from the system.

- Allow the flushing agent to drain completely into the container or drain pan.

- Refill with Clean Hydraulic Fluid:

- Close the drain plug or valve once all the flushing agent has been drained.

- Refill the hydraulic system with clean, recommended hydraulic fluid.

- Follow the manufacturer’s guidelines for the appropriate fluid type and fill level.

- Bleed the System:

- Bleed any air from the hydraulic system according to the manufacturer’s instructions or bleed procedures specific to your tractor model.

- This step ensures proper hydraulic system operation and eliminates any air pockets.

- Test the System:

- Start the tractor and engage the hydraulic system.

- Check for any abnormal noises, leaks, or performance issues.

- Operate the hydraulic system to verify that it functions smoothly without water-related problems.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

液压缸应用: