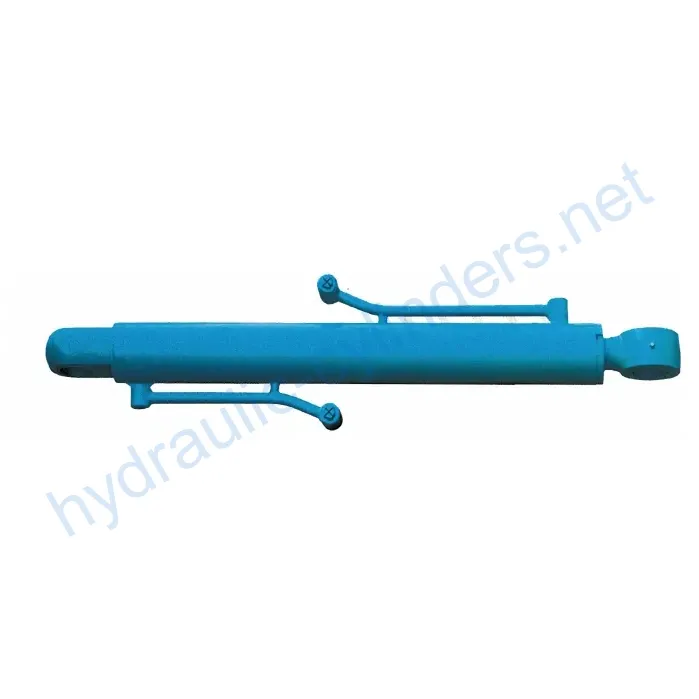

Bucket Cylinder For Volwa Cane Unloader DLS818-9A

Bucket Cylinder For Volwa Cane Unloader DLS818-9A

Introduction

A bucket cylinder is a specially designed hydraulic cylinder that is primarily used to control the movement of the bucket in heavy equipment such as excavators, backhoe loaders, and front-end loaders. Its main function is to enable the bucket to be lifted, lowered, and tilted, making it easier to handle various material handling tasks. In the hydraulic system, the bucket cylinder achieves precise control of the bucket by means of changes in hydraulic oil pressure, allowing operators to efficiently handle heavy loads and adapt to complex working environments and diverse operational needs.

Features

- High strength and durability: Usually made of high-strength steel or aluminum, it can withstand high pressure and heavy loads, adapt to harsh working environments, and is designed with wear resistance and corrosion resistance to extend its service life

- Efficient hydraulic operation: Smooth extension and retraction movements are achieved by utilizing the pressure of hydraulic oil, providing powerful pushing and pulling forces, suitable for handling heavy loads and complex tasks

- Various types: Single-acting (hydraulic used only in one direction) or double-acting (hydraulic used in both directions) cylinders can be selected according to operational needs. Some models are telescopic, allowing for greater extension without increasing external dimensions, suitable for applications with limited space.

- Easy to install: Our product is capable of replacing these hydraulic cylinders perfectly.

Applications

Bucket cylinders are widely used in various industries and equipment, including:

- Construction equipment: In excavators, they are critical for digging, loading, and moving soil or debris. In backhoe loaders, the bucket cylinder helps with both digging and lifting.

- Agricultural machinery: Used in front-end loaders for scooping, lifting, and transporting soil, hay, and other materials.

- Excavators: Bucket cylinders achieve digging actions by allowing the bucket to penetrate soil.

- Front-end loaders: In front-end loaders, they help with lifting and tilting loads efficiently.

Design Considerations And Selection Standards

Bearing capacity:

Bucket cylinders are designed to withstand high loads and pressures, which requires strict selection of materials, processing, and testing. To ensure the maximum bearing capacity, we use high-strength materials, such as steel and aluminum alloys, and the cylinder structure design is optimized for high load and pressure resistance.

Sealing and Durability:

Sealing plays a crucial role in the durability and reliability of bucket cylinders. We use various sealing components, such as piston seals, rod seals, and wiper seals, that can withstand abrasion and corrosion. Cylinder bodies and threaded end surfaces are finely processed to enhance wear resistance, and regular lubrication with hydraulic oil is necessary to maintain the sealing performance and extend service life.

Maintenance And Troubleshooting

Maintenance:

Regular inspection, lubrication, seal replacement, and calibration checks are common maintenance tasks that help to prolong the service life of bucket cylinders. During installation, it is essential to align the cylinder correctly and use adequate mounting brackets to secure it. We recommend following the recommended inspection, repair, and replacement procedures to maintain optimum performance, and we offer replacement parts and rebuilding services to extend the service life of your cylinder.

Troubleshooting:

Common issues that may arise with bucket cylinders include leaks, misalignment, and poor performance. To diagnose and solve these problems effectively, we recommend understanding the root cause by checking the hydraulic system, seals, and cylinder body for wear and damage. Proper alignment and lubrication are crucial to preventing these issues, and regular inspection and maintenance can help detect problems before they escalate.

About Our Company

We are a leading manufacturer and wholesale distributor of hydraulic cylinders in the domestic and international markets. Our company offers a comprehensive range of products, adheres to excellent quality, and relies on industrialized production management strategies in finely crafted manufacturing workshops. We constantly enhance our manufacturing platform from the application of technology talents, high-end digitalized manufacturing equipment, and professional detection systems. We have strong development capabilities and adhere to the principles of high efficiency, high precision, and high quality to meet diverse customer needs.

Professionalism:

Our team of experts has years of experience in the manufacturing and distribution of hydraulic cylinders. We use advanced technology and testing equipment to ensure the high quality of our products, and we offer customization services to meet customer-specific needs.

International Certification:

Our company has obtained international certification, such as ISO 9001, CE, and SGS, to ensure our products comply with industry standards and regulations.

Production Equipment:

Our company has invested in high-end digital manufacturing equipment to enhance our production capacity and improve product quality.

After-sales Service:

We provide excellent after-sales service to our customers, including installation guidance, technical support, and warranty services, to ensure customers have a hassle-free experience with our products.

Author: lyl

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

液压缸应用: